OPERATION & MAINTENANCE MANUAL SWE155F

Loosen drain valve underneath diesel oil tank to drain

water and deposit. Collect them with container. Fasten

valve the moment clean diesel oil is discharged.

4.5.1.6 Checking Hoses and Pipelines for Leakage, Interference Abrasion

Warning

Pressurized fluid can penetrate skin causing serious injury.

To prevent being injured, use a card board to search leakage. Be careful not to allow

high-pressure fluid to come into contact with body.

In case of accidents, contact experienced doctor for medical attention.

Warning

Exposed hydraulic oil and lubricant can cause fire and injury to person.

To avoid this hazard:

Stop the machine to firm level ground, lower bucket to ground.

Stop the engine, remove key from starting lock, set pilot safety lever to LOCK position.

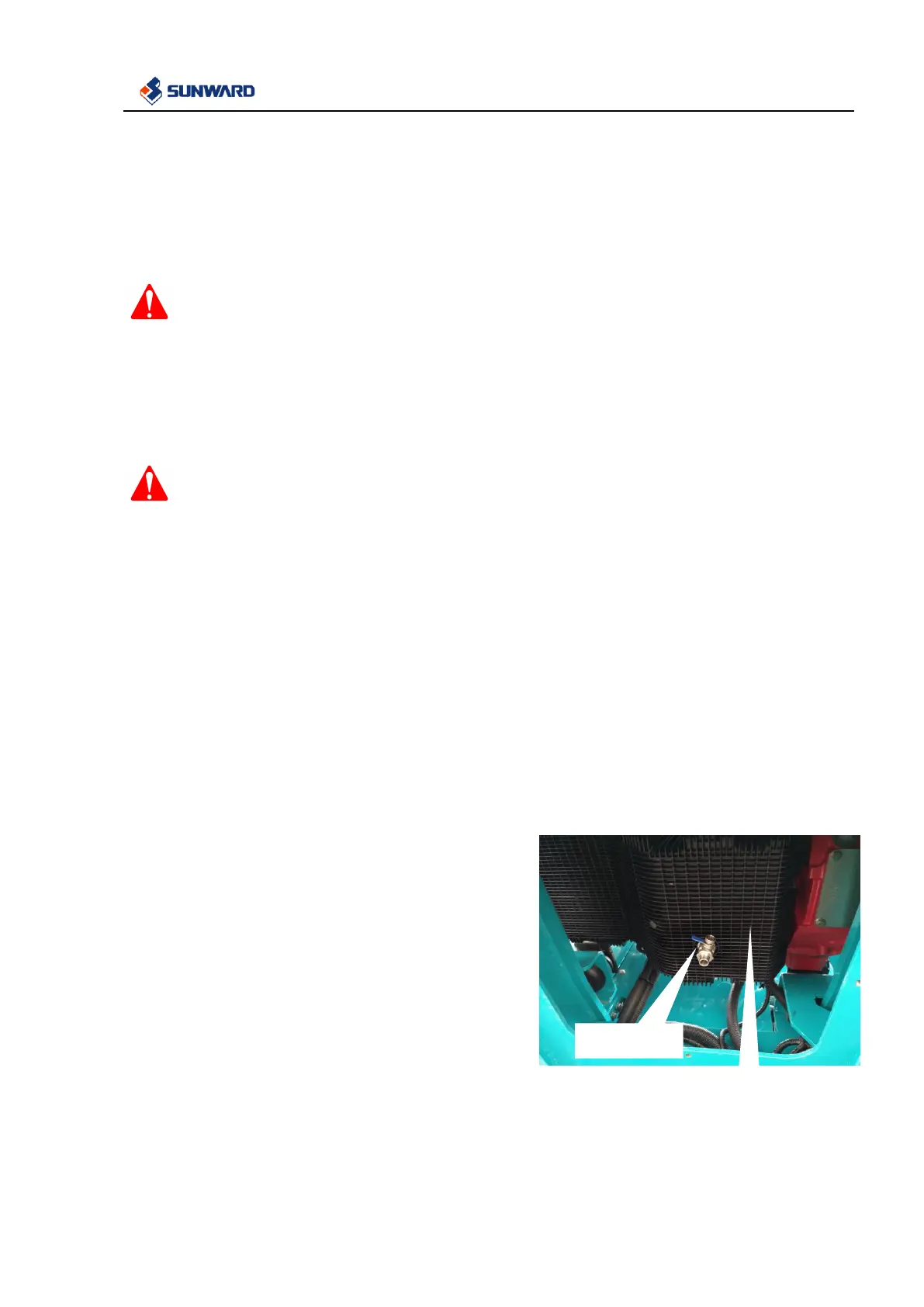

Check hose for any twist, abrasion, check hose clamp for looseness or lost. Check damages of cooler.

Check flange for looseness, and oil leakage.

When clamping, repairing or replacing any loosened, damaged, lost hose clamp, hose, pipe, oil cooler

and its flange bolt, do not bend or hit high-pressure hose, do not install twist or damaged hose or piping.

4.5.2 Maintenance in Initial 50 Hours of Running-in Period

The first 50 operation hours are the running-in period. It is

necessary to carry out following maintenance operation:

4.5.2.1 Replacing Engine Oil, Oil Filter Element

1) Start engine to warm up oil without overheating.

2) Lower bucket to ground, stop the machine at level

ground. Turn off auto-idle switch to run machine

unloaded at low speed for 5 minutes.

【Important】

Stopping engine improperly can cause damages

to turbocharger.

3) Set starting key to OFF position, stop engine, remove

the key from starting lock, set pilot safety lever to

LOCK position.;

Loading...

Loading...