79

9

SYSTEMA EOLO RT rev. 09ENIT04052021

MANUTENZIONE

9.2 ANOMALIES AND REMEDIES

In case the device does not work or works in the way incorrect, it must be turned o. All elements must be

repaired or replaced by specialized personnel. Spare parts must be original. The use of the device can be

dangerous if these principles are not respected.

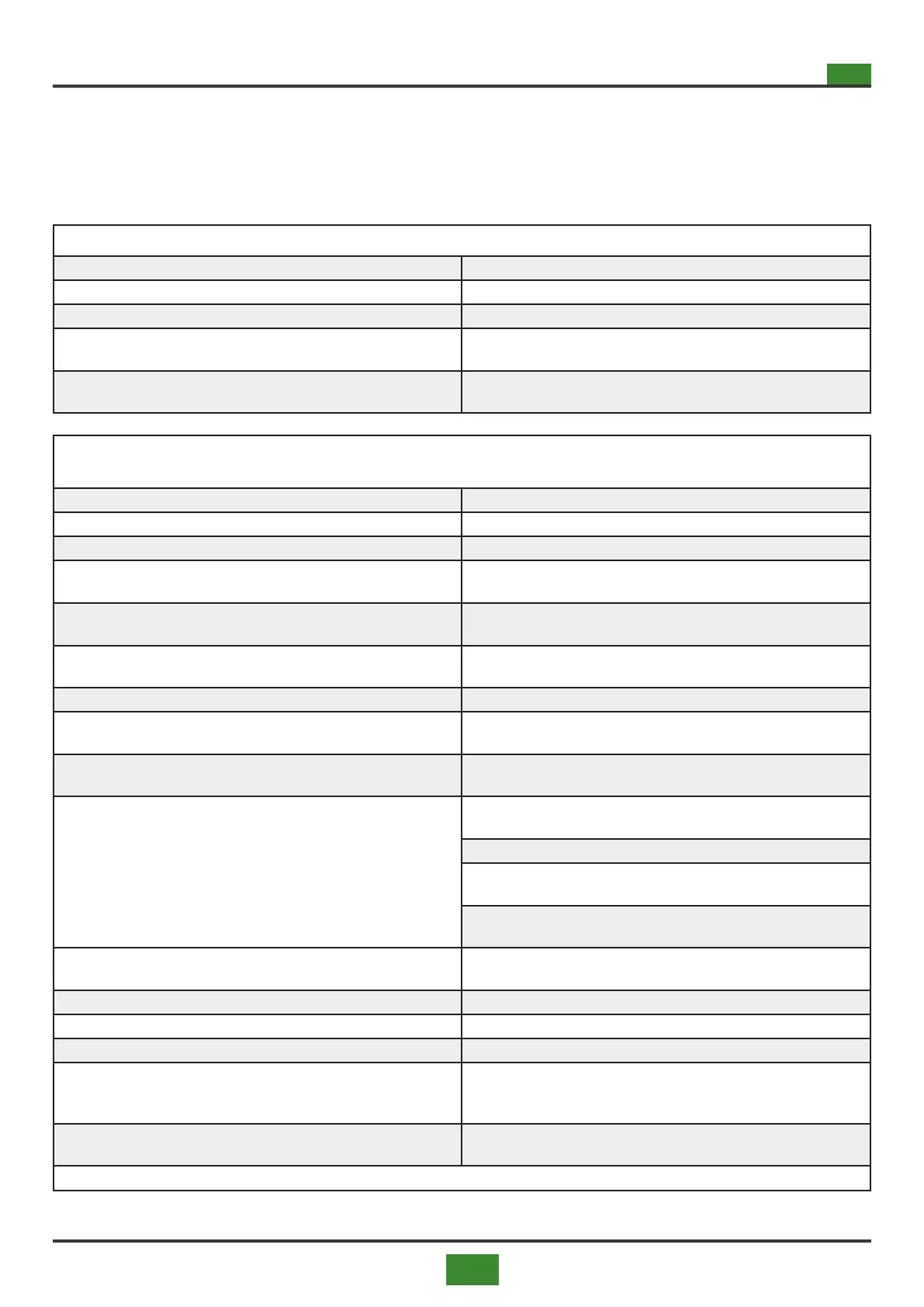

ANOMALY: the appliance does not switch on

CAUSES REMEDIES

1) Lack of power supply 1) Check the power supply

2) Motherboard fuses blown 2) Replace fuses

3) No communication between the internal control board and the com-

mand and external control panel

3) Vericare collegamenti elettrici e comunicazione, in caso di guasto

sostituire o scheda interna o quadro di comando e controlo

4) There is no power

4) Vericare la posizione degli interruttori sui quadri comando e sul

quadro generale

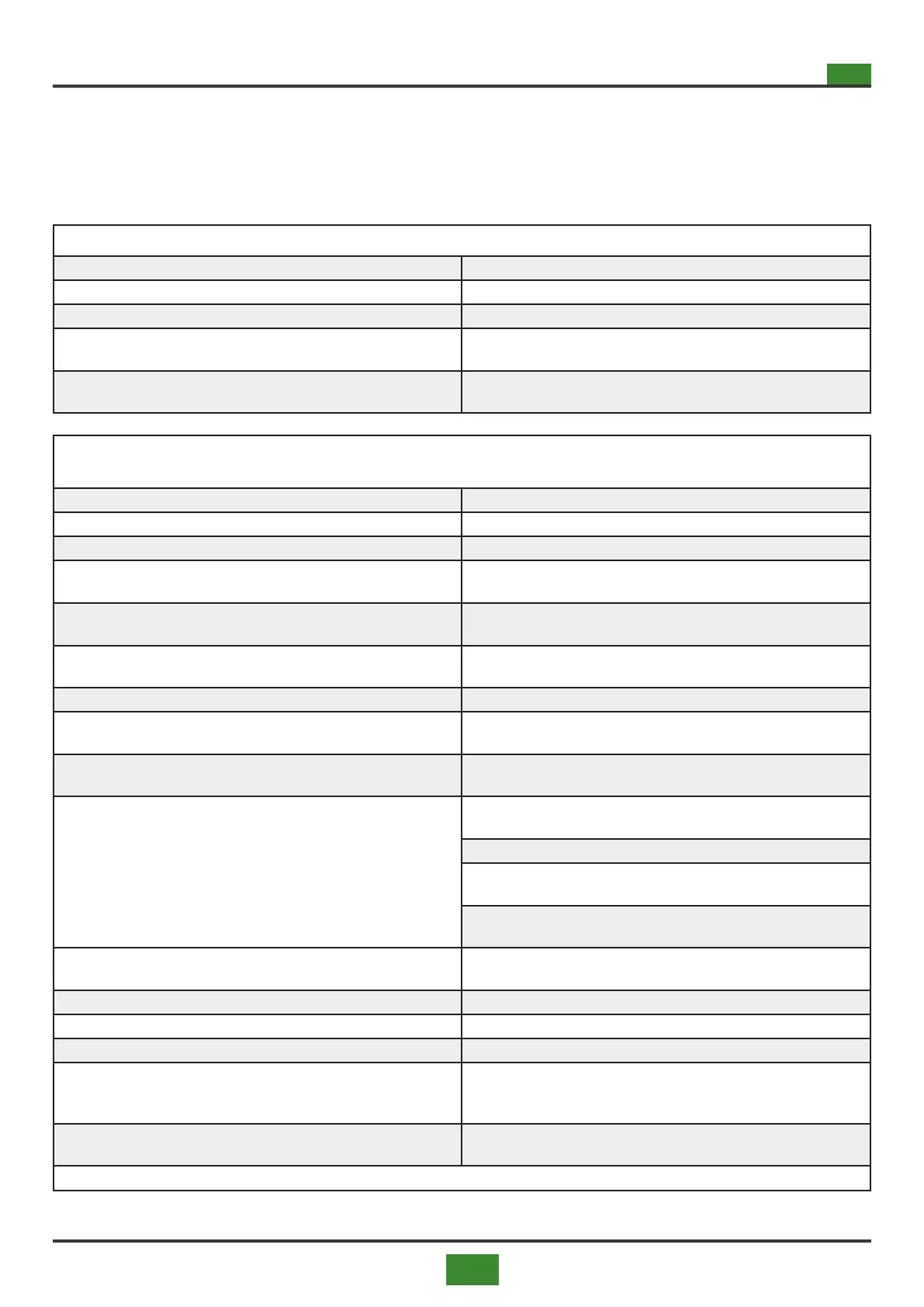

ANOMALY: the appliance does not turn on and after three ignition attempts it goes into lockout, on reset,

after three more attempts it continues to lock out

CAUSES REMEDIES

1) Power supply reversed between phase and neutral 1) Connect correctly and respect the phase and neutral polarity

2) Lack of gas in the burner 2) Check the gas supply line

3) Wrong type of gas

3) Check that the type of gas complies with that indicated on the plate.

Contact assistance or authorized and qualied personnel.

4) Wrong gas pressure

4) Check the pressure with the values shown on the plate. Seal the

regulating organ of the gas valve after calibration.

5) The ignition electrode (s) are incorrectly positioned or not working

5) Position the electrode / s correctly, see diagram in this booklet or

replace them with original spare parts

6) Poor grounding 6) Check the grounding

7) Ignitor broken

7) Check if the discharge occurs and / or replace it with an original

spare part

8) Control unit faulty

8) Check the operation of the control unit and / or replace it with an

original spare part

9) Gas valve does not activate

9.1) Check the gas supply on the valve and its operation

replace with original spare parts if necessary

9.2) Motherboard faulty replace with original spare parts

9.3) Check operation of the gas valve coils. Replace with original parts

if necessary

9.4) Check the operation of the control unit, replace with spare parts

originals if necessary

10) The valve opens but there is no gas at the valve outlet towards the

burner premix fan

10) Gas valve lter dirty or clogged with installation residues, check

ll lter and clean or replace lter with original spare parts

11) Presence of air in the gas supply channel 11) If necessary, bleed the air from the system

12) Dirty combustion head 12) Clean the combustion head and check operation

13) Gas nozzle blocked 13) Clean the gas nozzle and check operation

14) Wrong parameters of the burner

14) Check and set the gas parameters correctly as indicated in this bo-

oklet. The operation can be carried out by assistance or by authorized

and qualied personnel.

15) Wrong parameters of the PWM burner in burner ignition

15) Check parameter Y2 and / or set it by increasing it gradually until

correct ignition

CONTINUED ON NEXT PAGE

Loading...

Loading...