3-106

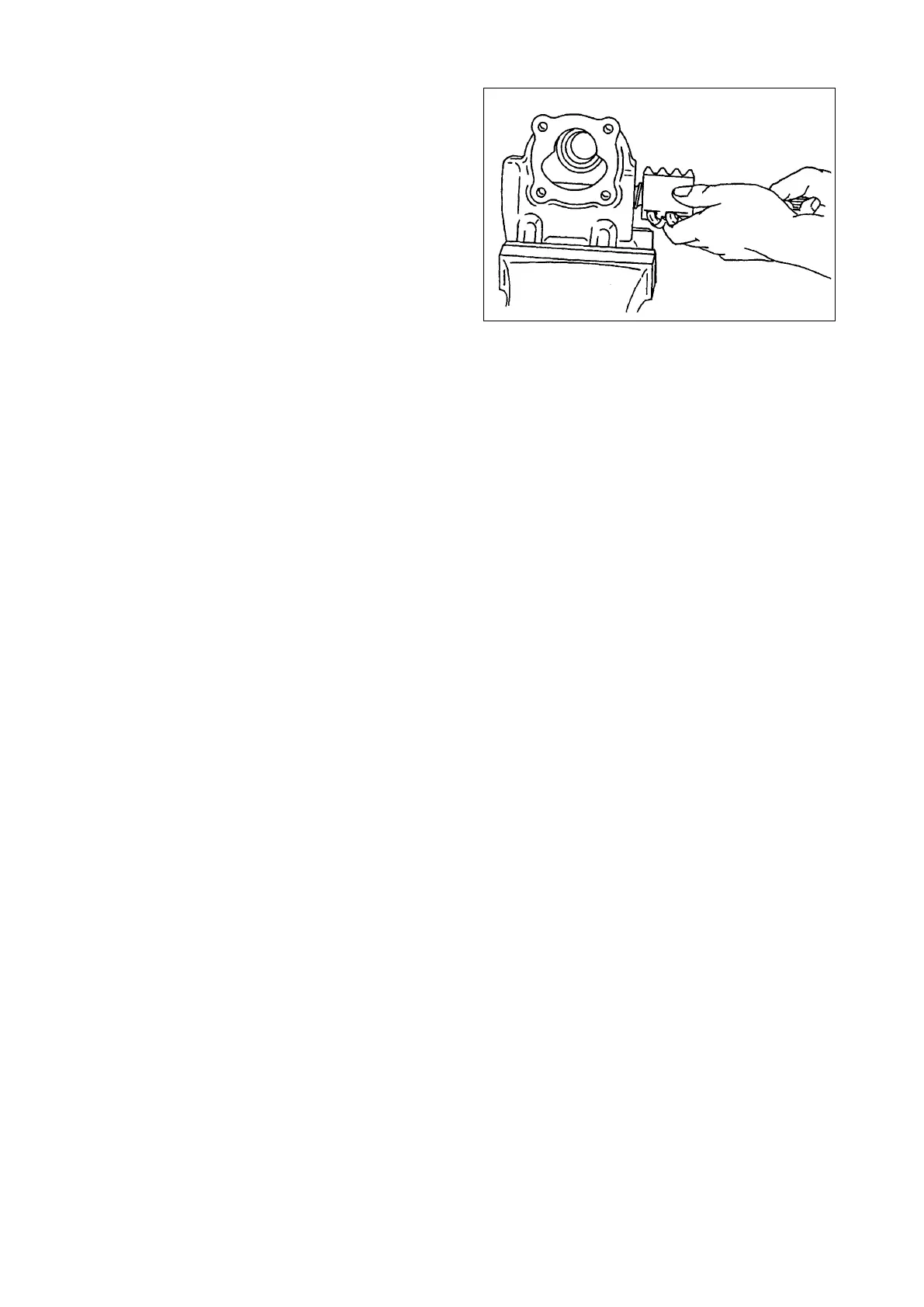

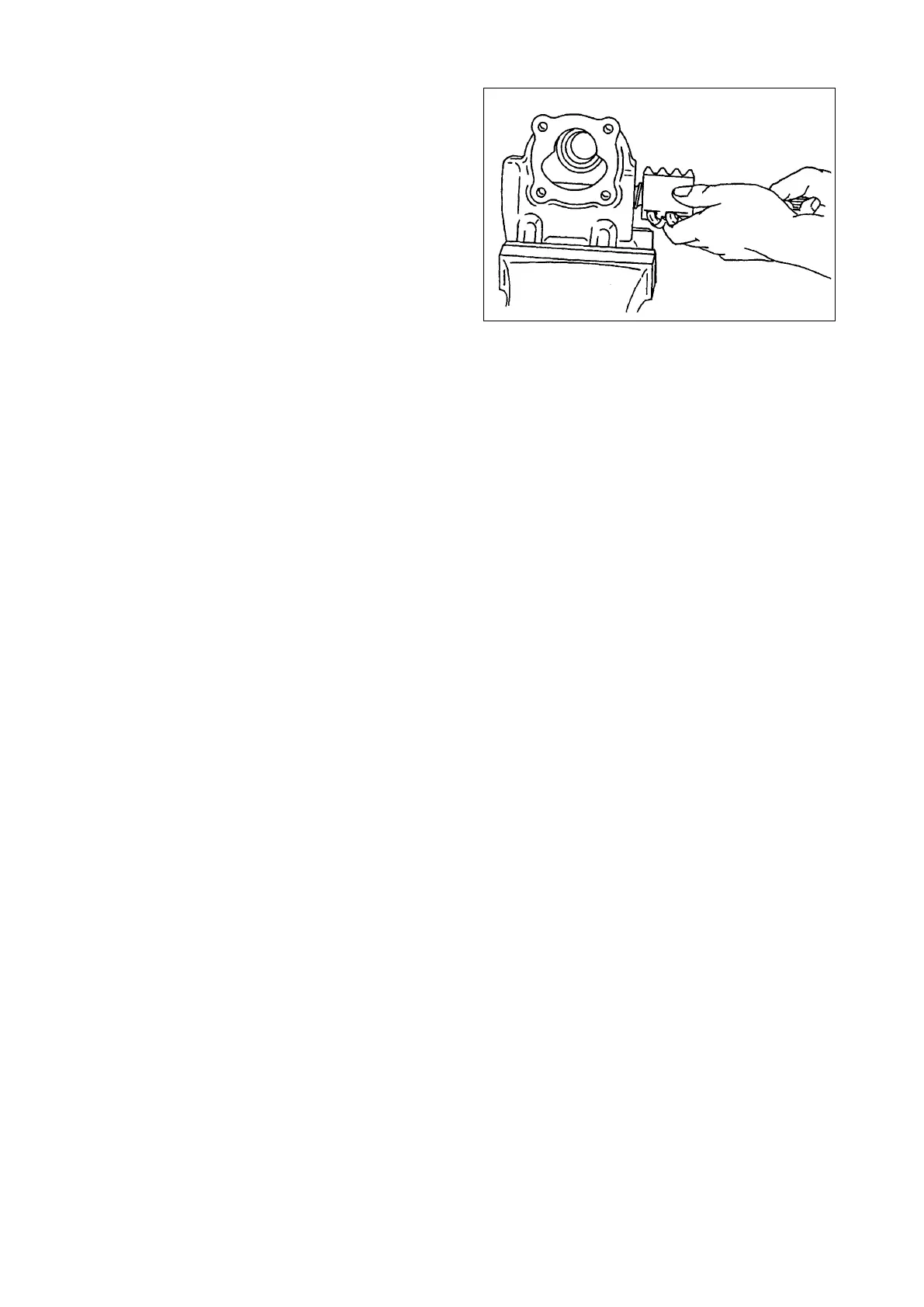

Fig. 3.342

⑧ Remove the ball nut assembly from the gear

box carefully. Make sure to keep the ball nut

assembly horizontally at all times. If it is

turned vertically, the ball nut may fall off by

itself and get damaged, which will prevent the

ball nut assembly from operating properly.

■ INSPECTION

Clean all the disassembled metal parts in clean oil. The “O”-rings and oil seals must be replaced with

new ones. After cleaning those metal parts, check them for scratches, wear, or cracks. Place them in a clean

location to keep them free of dust and dirt.

① Replace the “O”-rings and oil seals with new ones. Replace the side cover bushing with a new one if it

is damaged or worn.

② Check the ball nut operation. If it fails to operate smoothly, clean it by operating it in a oil bath. Also

check the threads on the nut for stripping, nicks, indentations, or abnormal wear. If any defects are

found, replace the ball nut assembly with a new one.

③ Check the sector shaft gear teeth for scoring. Also check the sector shaft for excessive wear. Replace as

needed.

④ Check the radial bearings of the gear box assembly and the side cover bushing for wear. Replace any

defective parts with new ones.

⑤ Check the radial bearings in the top cover. If any damage is found, replace them with new ones.

⑥ Check the control valve as follows:

1) Checktheinnersurfaceofthevalvehousing,payingspecialattentiontotheorice,fordents.Ifany

defects are found, replace the complete control valve assembly with a new one.

2) Checkthespool’souterdiameterandtheoricefordentsordamage.Replaceanydefectivepartswith

new ones.

3) Check all the springs for cracks or breaks. Replace any defective spring with a new one.

4) Check to see if the reaction pistons slide smoothly in the valve housing. If defective, replace the

complete valve assembly with a new one.

Loading...

Loading...