1-17

1.2 BASIC SERVICING KNOWLEDGE

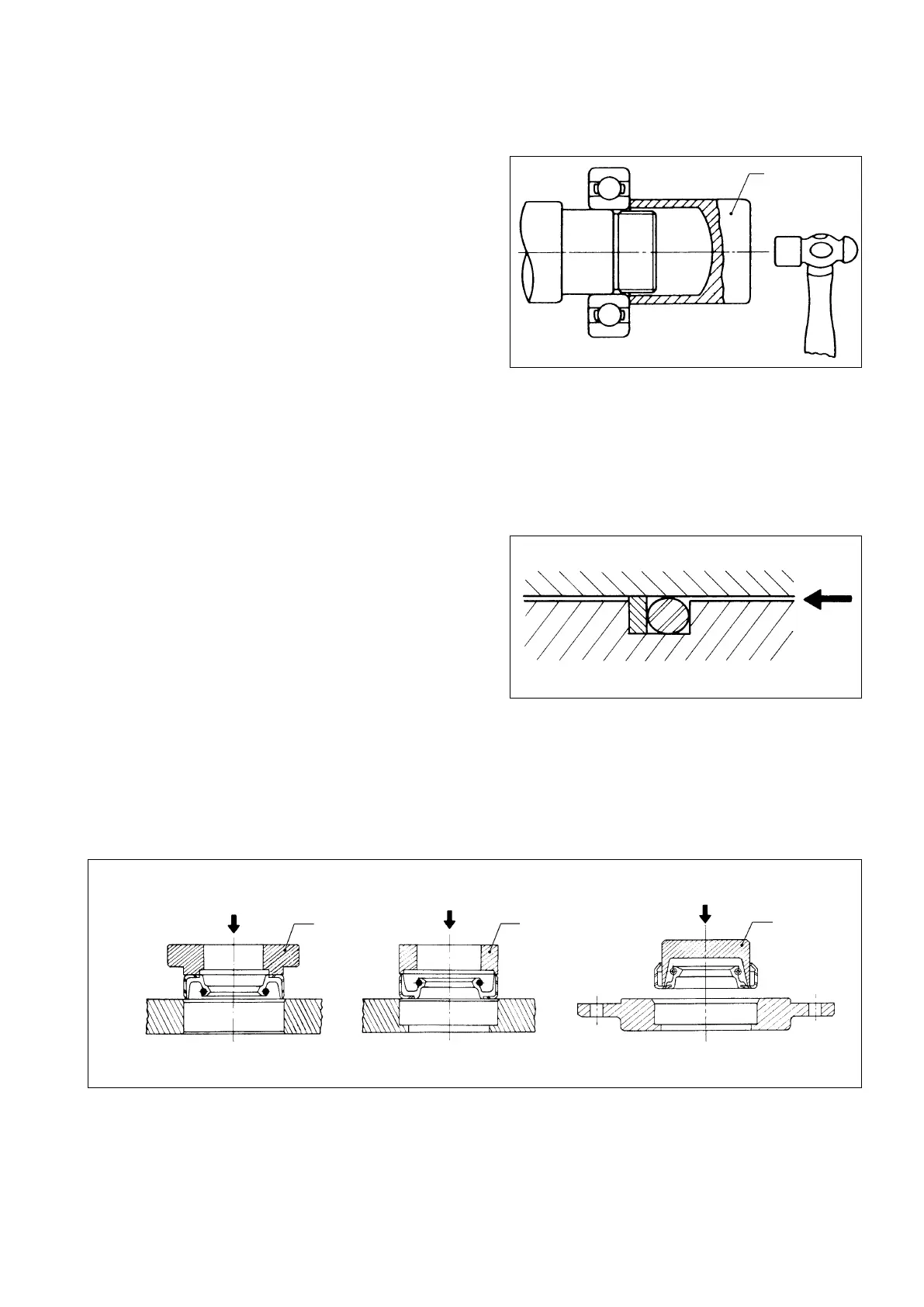

1. Installing bearings

When installing a bearing onto a shaft, tap its inner

race with a mallet as shown in Figure 1.1. When installing

a bearing into a case, tap its outer race.

When removing, use the same procedure as for

installing.

2. “O”-rings

① Use “O”-rings free from molding fault or damage.

② Clean “O”-rings and their mounting area and apply grease or hydraulic oil to them.

③ When installing “O”-rings, do not expand them so excessively that they suffer permanent deformation. Also

do not roll them when installing; otherwise they might stay twisted, causing oil leakage.

④ When using an “O”-ring and back-up ring as a set,

such as when hydraulic pressure is high, position the

“O”-ring at the side which receives the oil pressure.

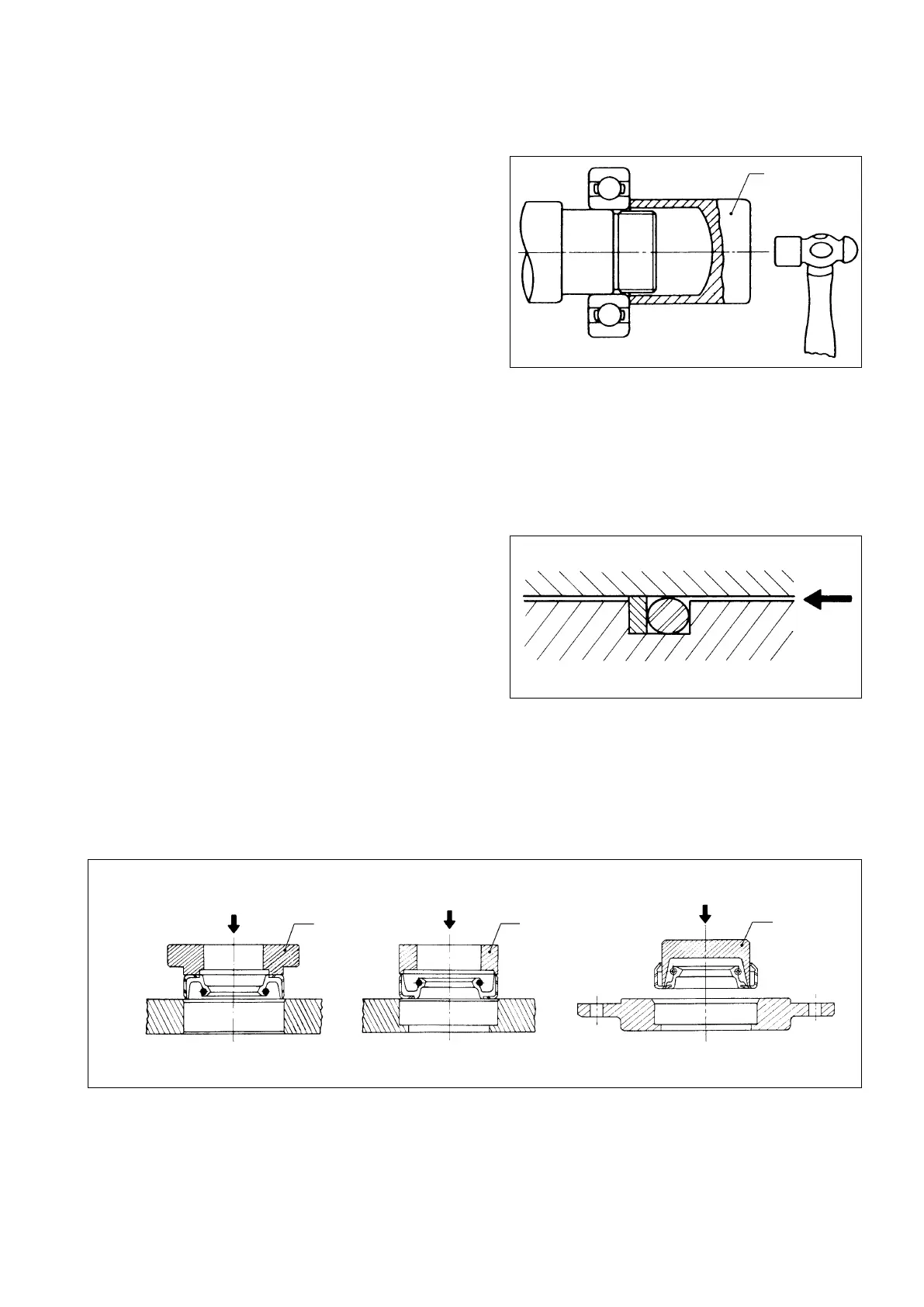

3. Oil seals

① Oil seals should be installed with the seal lip pointed toward the lubrication or hydraulic oil.

② When installing an oil seal on a housing, apply a thin coat of packing cementing agent on the oil seal outer

ring and inside the housing to prevent oil leakage through the fitting area. It is recommended to use a

suitable jig to apply uniform pressure when mounting oil seals.

Fig. 1.1 Installing bearings

JIG

Fig. 1.2 “O”-ring location

Pressure

Fig. 1.3 Installing Oil Seal

JIG JIG

JIG

Loading...

Loading...