Calibration

6–6

1502C MTDR Service Manual

7. Rotate DIST/DIV counterclockwise to its far stop. The switch reading on the

display should be 15.

8. Slowly rotate this control clockwise to its far stop. Each position should

increase the switch reading one count, starting at 15 and ending with 25.

9. The display should currently show a V

P

of 0.30. Slowly rotate the left V

P

control

to full clockwise. Each click should correspond to the front-panel control

setting.

10. Rotate the right V

P

control to full clockwise. Again, the LCD reading should

match the front-panel control setting. The final reading with both controls fully

clockwise should be 0.99.

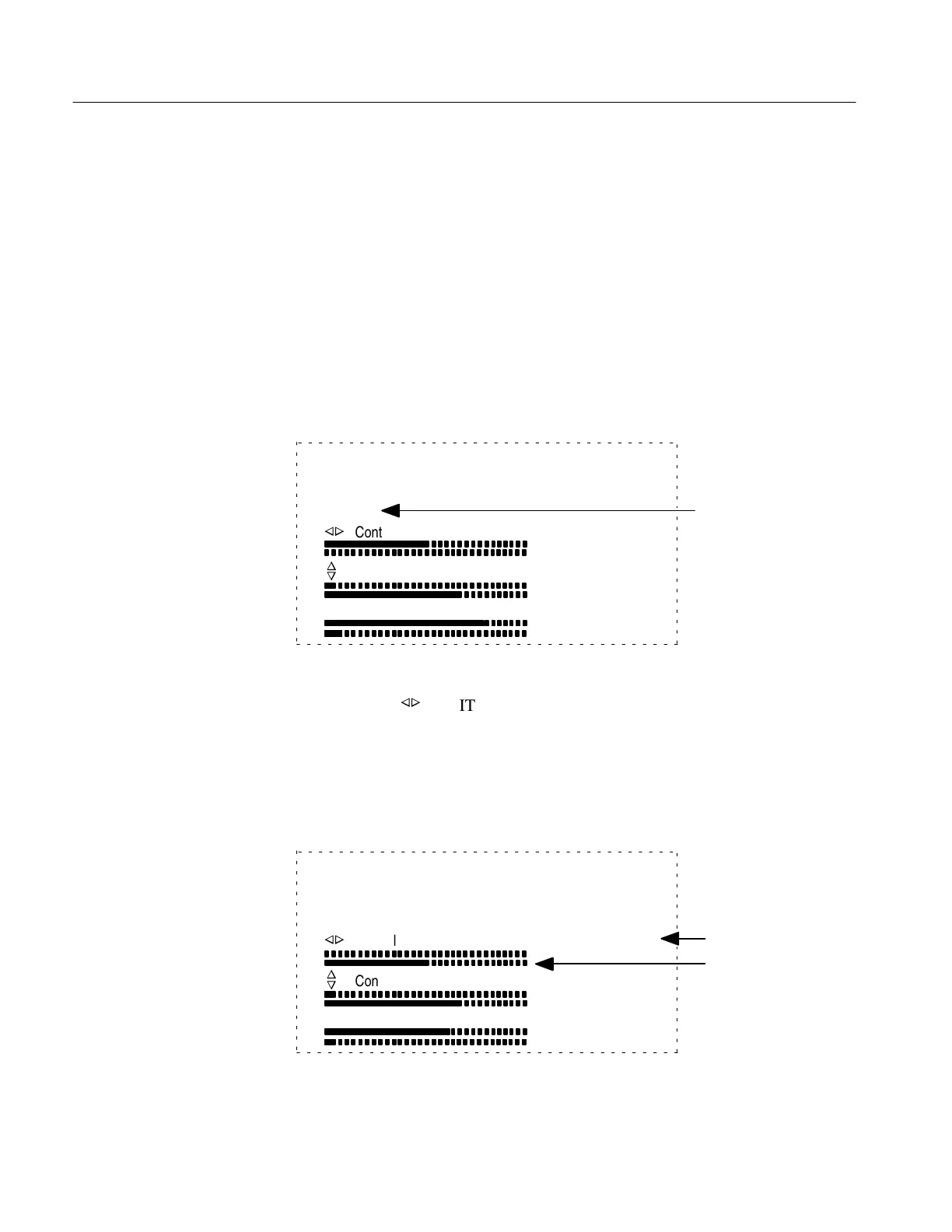

Front Panel Diagnostic, test all switches.

Hold down MENU button to Exit.

Switch: 1 temp: 84

Vp: 0.30

n

o

n

o

Control

Control

Vertical Scale

142

11

190

0

181

24

Vp Reading

Figure 6–7: Front Panel Diagnostic Display

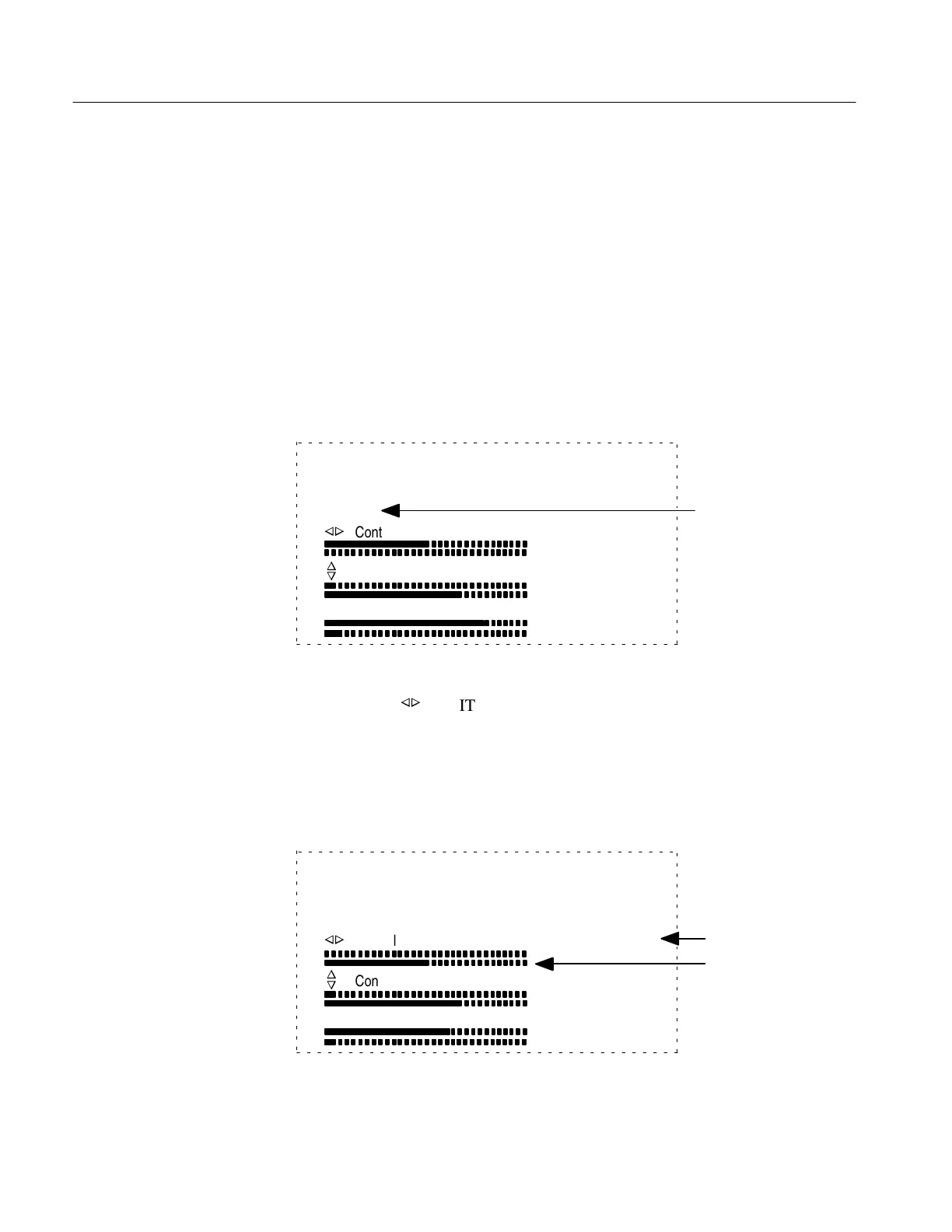

11. Rotate the

n

o

POSITION control, slowly in either direction. The bar graph

shown on the display represents the two elements of each control. The readings

to the right of the bar graph represent numbers used by the instrument to

calculate the position of the knob. As the control is rotated, these values and the

bar graph will change. The lower value in each column should be between 0 and

10 while the higher number is between 245 and 255.

Front Panel Diagnostic, test all switches.

Hold down MENU button to Exit.

Switch: 35 temp: 82

Vp: 0.99

n

o

n

o

Control

Control

Vertical Scale

0

12

172

142

181

8

Bar Graph

Corresponding

Numbers

Figure 6–8: Front Panel Diagnostic Display

Artisan Technology Group - Quality Instrumentation ... Guaranteed | (888) 88-SOURCE | www.artisantg.com

Loading...

Loading...