AIR FORCE

T033A1-13-496-1

NAVE

LEX

0969-LP-170-0010

Maintenance Instructions

NOTE

(5)

Semiconductor

Lead Configurations.

Typical

semiconductor

lead configurations are

shown in Figure

5-3.

b.

Troubleshooting

Techniques. The following pro-

cedures are

arranged in an order that checks the simple

trouble

possibilities

before

proceeding with extensive

troubleshooting.

The first few checks ensure proper con-

nection,

operation, and calibration.

If the trouble is not

located by

these checks, the remaining

checks should aid

in

locating the defective component.

(1)

Check

Control

Settings. Incorrect control settings

can

indicate

a

trouble that does not

exist.

If

there is any

question about the correct function

or operation of any

control,

see

the Operation Instructions section.

(2)

Check Associated Equipment. Before proceeding

with

troubleshooting, check

that the equipment used with

this instrument is operating correctly.

Check that the signal

is

properly connected and

that the interconnecting

cables

are not defective. Also,

check the power

source.

(3)

Check

Instrument Calibration.

Check

the cali-

bration of

this

instrument,

or the affected

circuit if

the

trouble exists in one circuit.

The apparent

trouble may

only be misadjustment

that can be

corrected

by

calibration.

(4)

Visual Check. Visually

check

the portion of the

instrument in

which the trouble

is located.

Many troubles

can

be located

by

visual

indications

such

as

unsoldered

con-

nections, broken wires,

damaged

circuit boards,

and dam-

aged

components.

(5)

Isolate

Trouble

to a Circuit.

Using the trouble-

shooting

chart Figure

5-2,

isolate trouble

to a

particular

circuit.

The

symptom often

identifies

the defective

circuit.

Trouble

appearing

in more

than one

circuit can

indicate

possible

power

supply problems.

Power

supply tolerance

and

ripple limits

can

be checked

using Table

5-5.

Power

supply

disconnect

jumpers

are provided

for each of

the

sup-

plies. Refer

to the

schematics and

circuit

board illustrations

for their

location.

These

jumpers can be

unsoldered

to

dis-

connect

the circuit

load from

most of

the supplies.

Each

unregulated supply

contains

a fuse

for

circuit

protection.

(6)

Check

Circuit

Board

Interconnections.

After

the

trouble

has been

isolated

to a

particular circuit,

check

for

loose

or broken

connections,

improperly

seated

transistors

and

heat

damaged

components.

(7)

Check

Voltages

and

Waveforms.

Often the

de-

fective

component

can

be

located

by checking

for

the

correct

voltage

or

waveform

in

the

circuit.

Typical

volt-

ages

are

given

on

the

diagrams.

Waveforms

are

shown on

the

circuit

diagram

apron.

Voltages

and waveforms given

on the

diagrams are

not

absolute and therefore

may vary

slightly

be-

tween

instruments.

To

obtain

operating

conditions

similar

to

those

used to take

these readings,

see the

voltage and

waveform

set up procedures

in the

Diagrams

section.

Individual deviations

should

be noted

on the

schematics for future

reference.

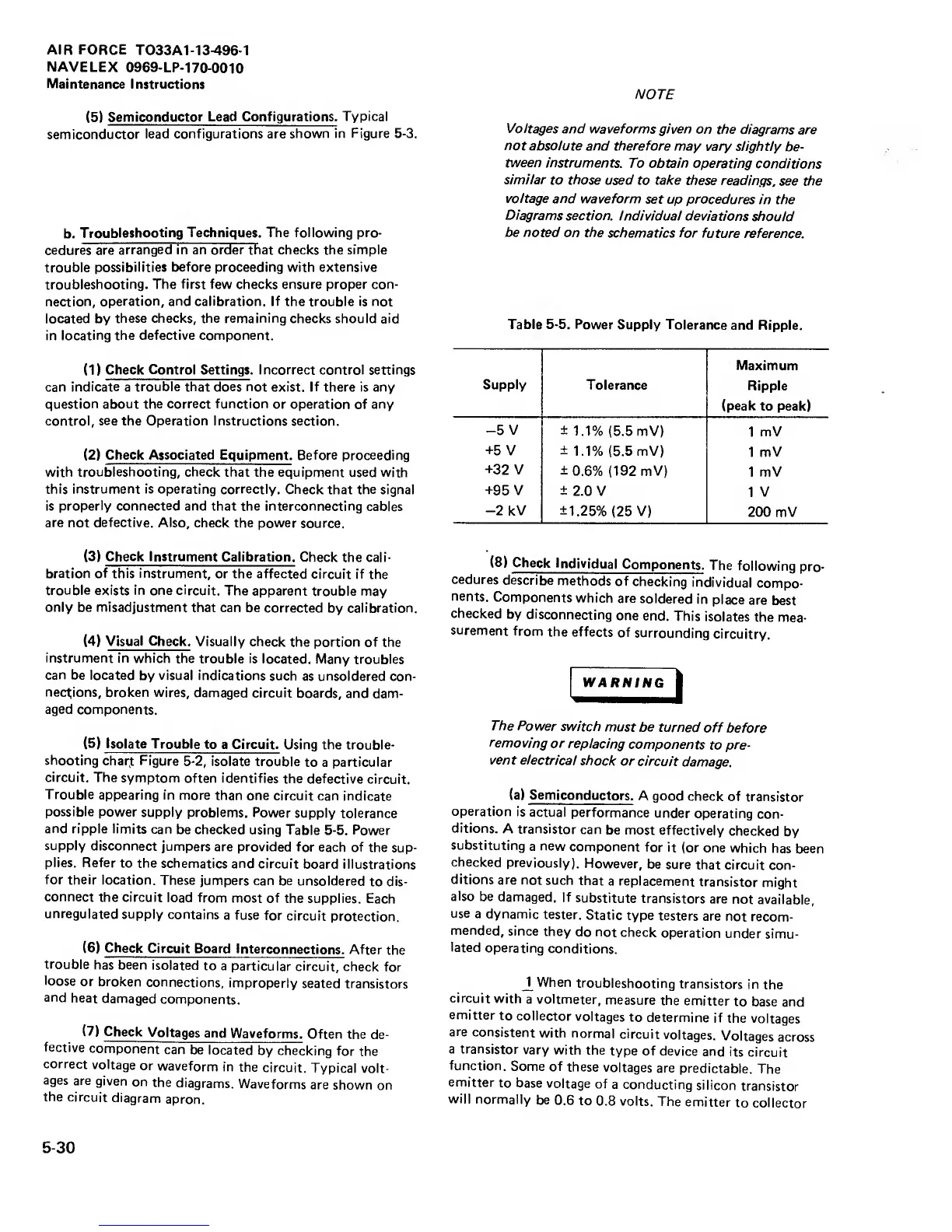

Table

5-5.

Power

Supply

Tolerance

and Ripple.

Supply

Tolerance

Maximum

Ripple

(peak

to peak)

-5

V ±

1.1%

(5.5

mV)

1 mV

+5

V

±1.1%

(5.5

mV)

1 mV

+32

V

±0.6%

(192

mV)

1 mV

+95

V ±

2.0 V

1 V

-2

kV

±1.25%

(25

V)

200

mV

(8) Check

Individual

Components.

The

following

pro-

cedures

describe

methods

of

checking

individual

compo-

nents.

Components

which

are

soldered

in

place

are

best

checked

by

disconnecting

one

end.

This

isolates

the

mea-

surement

from

the

effects

of

surrounding

circuitry.

WARNING

The

Power

switch

must be

turned

off

before

removing

or

replacing

components

to

pre-

vent

electrical

shock

or circuit

damage.

(a)

Semiconductors.

A good

check

of

transistor

operation

is

actual

performance

under

operating

con-

ditions.

A

transistor

can be

most

effectively

checked

by

substituting

a

new

component

for

it (or

one which

has

been

checked

previously).

However,

be

sure that

circuit

con-

ditions

are

not

such

that

a replacement

transistor

might

also

be

damaged.

If

substitute

transistors

are

not

available,

use

a

dynamic

tester.

Static

type

testers are

not recom-

mended,

since

they

do

not check

operation

under

simu-

lated

operating

conditions.

When

troubleshooting

transistors

in

the

circuit

with

a

voltmeter,

measure

the

emitter

to

base and

emitter

to

collector

voltages

to

determine

if

the

voltages

are

consistent

with

normal

circuit

voltages.

Voltages

across

a transistor

vary

with

the

type of device

and its

circuit

function.

Some of

these

voltages

are

predictable.

The

emitter

to base

voltage

of

a

conducting

silicon

transistor

will

normally

be

0.6

to

0.8 volts.

The

emitter

to

collector

5-30

Loading...

Loading...