AIR

FORCE

T033A1-13-496-1

NAVELEX

0969-LP-1

70-0010

Maintenance

Instructions

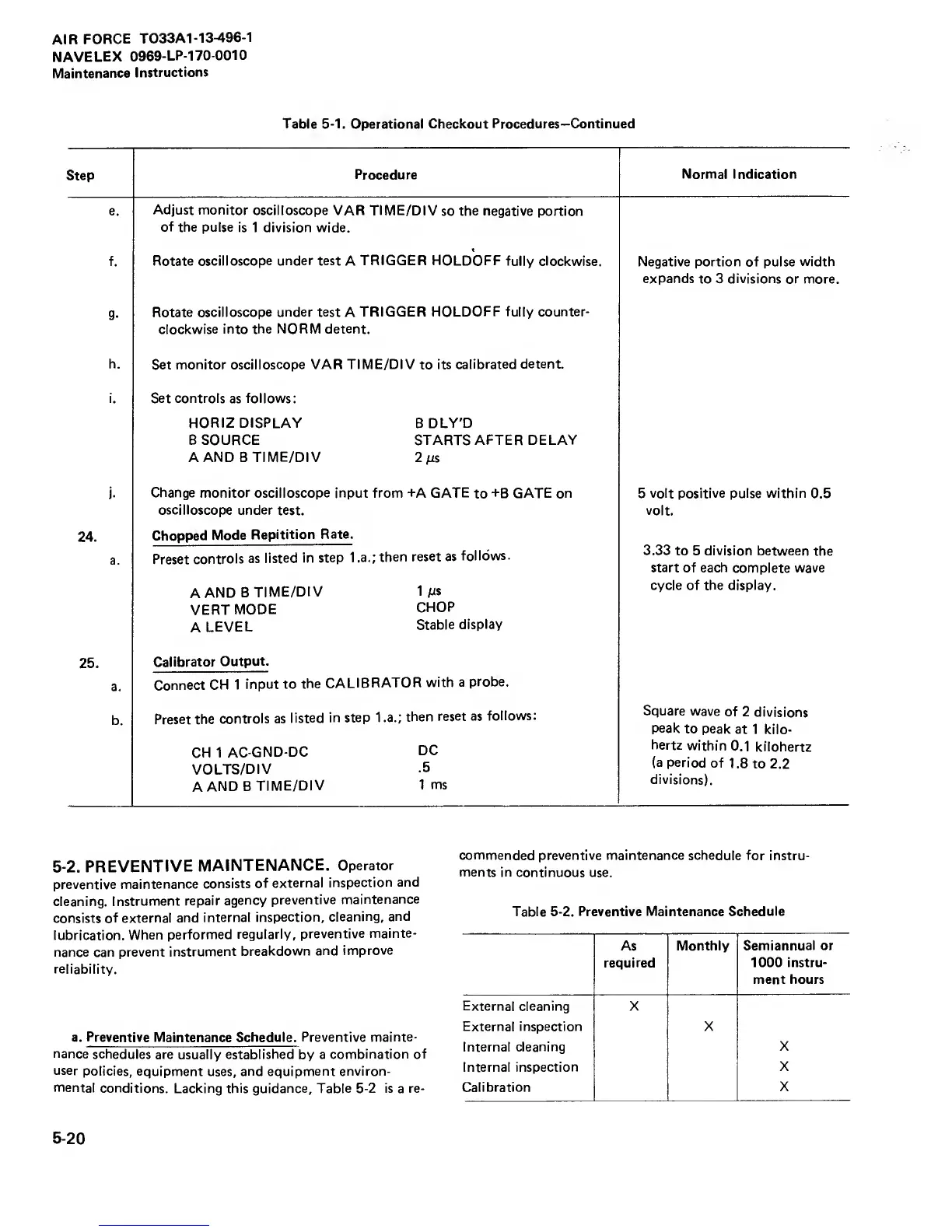

Table

5-1.

Operational

Checkout Procedures—Continued

Step

Procedure

Normal Indication

e.

Adjust

monitor

oscilloscope VAR TIME/DIV

so

the

negative portion

of

the pulse

is 1 division wide.

f.

Rotate oscilloscope

under test

A

TRIGGER HOLDOFF

fully clockwise.

Negative portion of pulse

width

expands

to 3

divisions

or more.

g.

Rotate oscilloscope

under test

A

TRIGGER

HOLDOFF fully counter-

clockwise

into the NORM detent.

h.

Set

monitor oscilloscope VAR TIME/DIV

to

its

calibrated

detent.

i. Set controls

as

follows:

HORIZ DISPLAY

B SOURCE

A

AND

B

TIME/DIV

B

DLY'D

STARTS

AFTER DELAY

2

^s

24.

a.

Change monitor oscilloscope input

from

-tA

GATE

to +B

GATE on

oscilloscope under test.

Chopped

Mode

Repitition

Rate.

Preset

controls

as

listed in

step

1 .a.;

then

reset as

follows.

A

AND

B

TIME/DIV

1

/iS

VERT

MODE

CHOP

A

LEVEL

Stable

display

5

volt positive pulse within

0.5

volt.

3.33

to 5 division

between the

start

of

each

complete wave

cycle of the display.

25.

Calibrator

Output.

a.

Connect

CH 1

input to

the

CALIBRATOR

with

a

probe.

b.

Preset the

controls as

listed

in step 1 .a.;

then

reset

as

follows:

CH 1

AC-GND-DC

DC

VOLTS/D

IV

.5

A

AND B

TIME/DIV

1

ms

Square

wave

of 2

divisions

peak

to peak

at

1

kilo-

hertz

within

0.1 kilohertz

(a

period

of

1.8

to 2.2

divisions).

5-2. PREVENTIVE

MAINTENANCE.

Operator

preventive

maintenance

consists

of

external

inspection

and

cleaning.

Instrument

repair

agency

preventive

maintenance

consists of

external

and

internal

inspection,

cleaning,

and

lubrication.

When

performed

regularly,

preventive mainte-

nance can

prevent instrument

breakdown

and

improve

reliability.

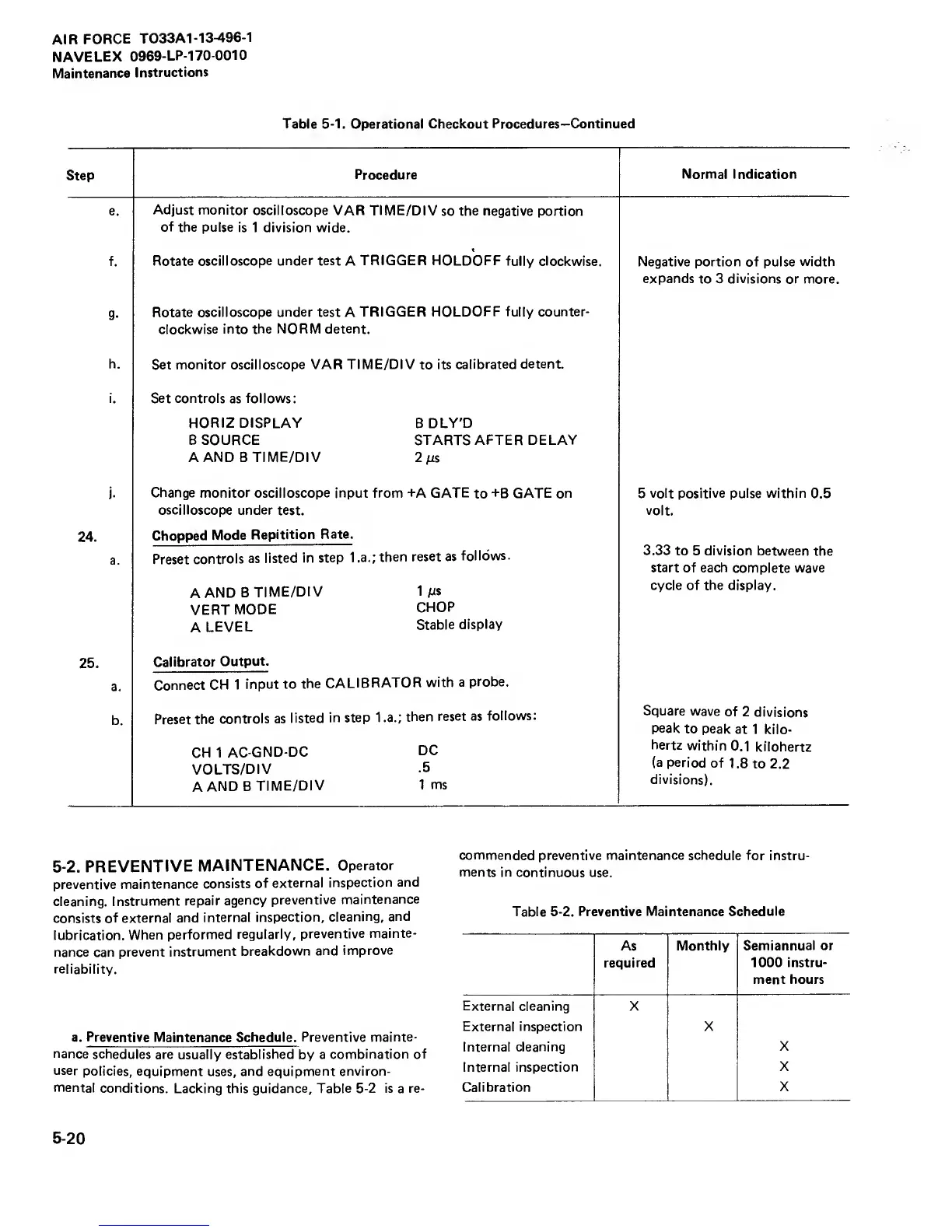

a. Preventive Maintenance Schedule.

Preventive mainte-

nance

schedules

are usually established

by

a

combination of

user

policies, equipment

uses,

and equipment environ-

mental

conditions. Lacking this guidance. Table

5-2

is

a

re-

commended preventive maintenance schedule for

instru-

ments in

continuous use.

Table

5-2.

Preventive

Maintenance Schedule

—

As

required

Monthly

Semiannual or

1000 instru-

ment hours

External cleaning X i

External inspection X

Internal

cleaning

X

Internal

inspection

X

Calibration

X

5-20

Loading...

Loading...