CUTMASTER 40MM

Manual 0-5085 5-23 SERVICE

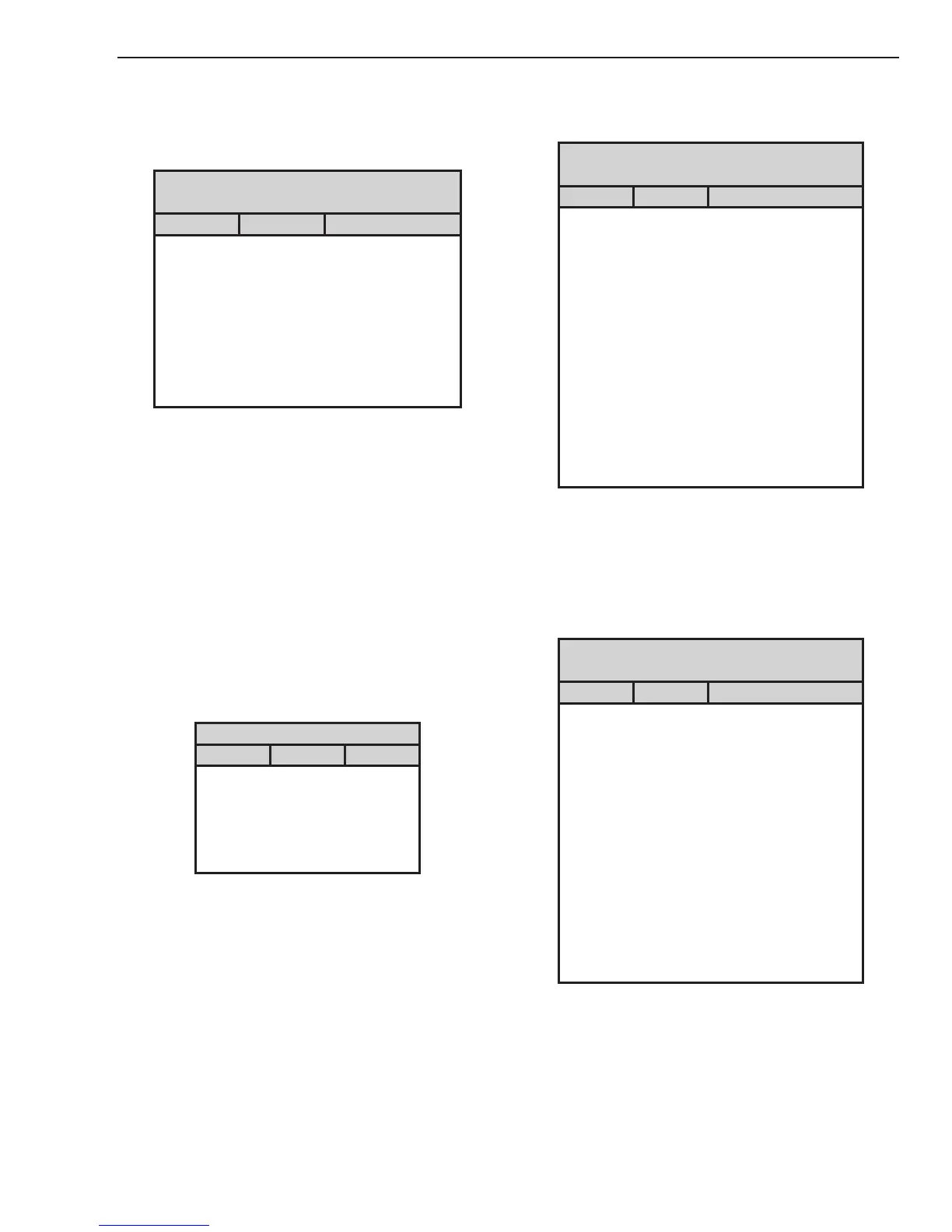

H. PCB 5 Output Diode D2 Test

1. Disconnect transformer wires from Main PCB 5

terminal SEC1.

2. Using an ohmmeter perform the following checks:

PCB 5 – D2

Test points located on PCB 5

Meter (+) Meter (-) Indication

CHOKE1 SEC1 Forward Bias

CHOKE1 SEC2 Forward Bias

SEC1 CHOKE1 Reversed Bias

SEC2 CHOKE1 Reversed Bias

+OUT_1 SEC1 Reversed Bias

+OUT_1 SEC2 Reversed Bias

SEC1 +OUT_1 Forward Bias

SEC2 +OUT_1 Forward Bias

I. PCB 1 Pilot IGBT Test

1. Disconnect wire E35 from Main PCB 1 terminal

TIP1.

2. Using a multimeter with a diode test scale, place

the positive probe on PCB 1 terminal TIP1 and

the negative probe on PCB 1 terminal WORK1

and check for a forward Biased diode reading.

3. If the test reveals a failed component, replace

Main PCB 1. If no problem is found, reconnect

wire to Main PCB.

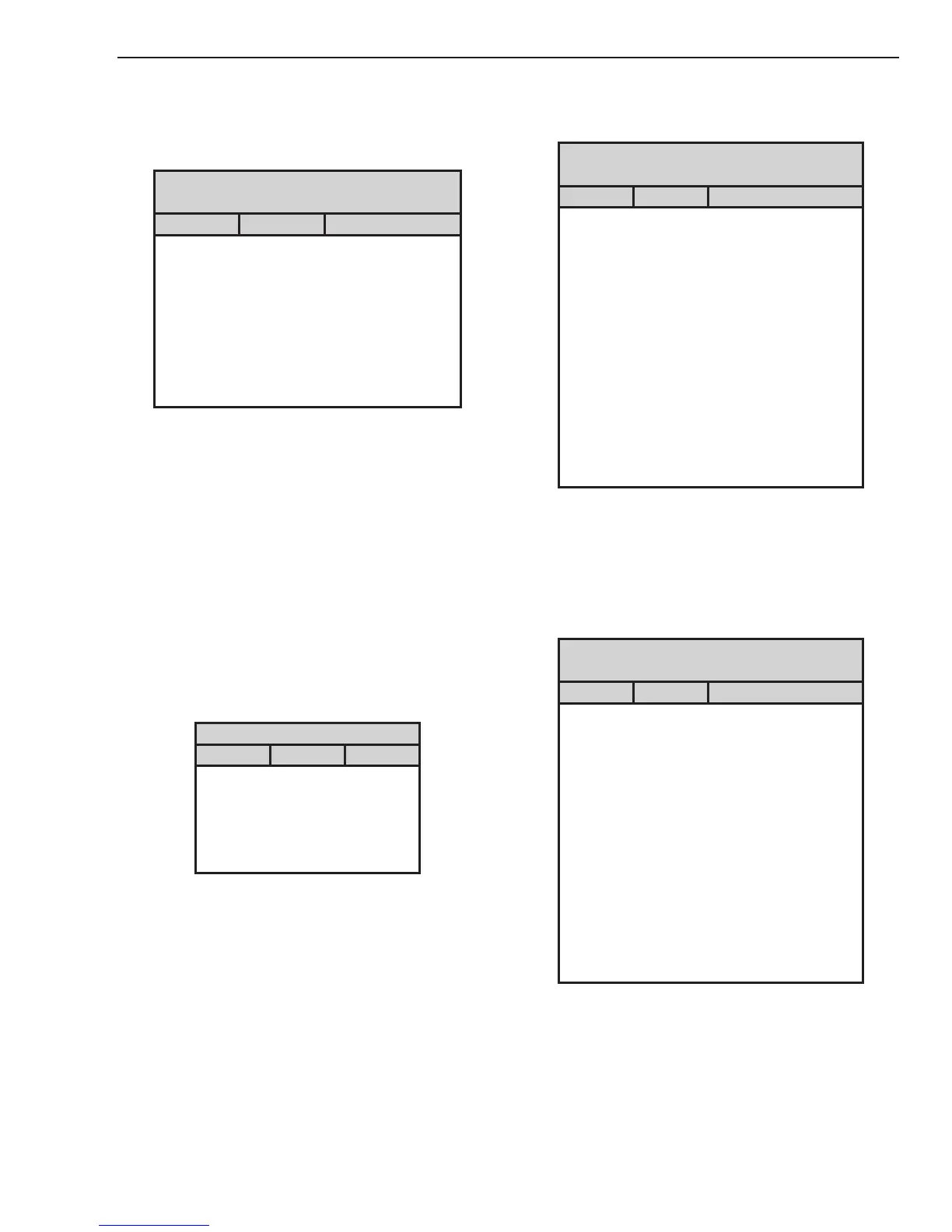

J. PCB 2 Capacitor / Relay Test (with PCB 2

removed from the unit)

1. Using an ohmmeter perform the following checks:

PCB2Capacitor&RelayTest

Meter + Meter - Indication

MTH2 MTH4 Charging

MTH8 MTH7 Charging

MTH7 MTH4 Open

MTH8 MTH2 Open

MTH8 MTH4 Open

Most meters will show a charging action. Initially a

low resistance will be shown and then the resistance

will start to increase. If the meter probes are reversed

the reading will decrease to zero, then start charging

in the opposite polarity.

2. If test reveals a failed component, replace Capaci-

tor PCB 2.

K. PCB 1 Input Diode Test. (With PCB 2

removed form unit)

1. Using an ohmmeter perform the following checks:

Input Diode Module D1 on PCB 1

Test points located on PCB 1

Meter (+) Meter (-) Indication

AC1 TP2 Forward Biased Diode

AC2 TP2 Forward Biased Diode

AC3 TP2 Forward Biased Diode

TP2 AC1 Reverse Biased Diode

TP2 AC2 Reverse Biased Diode

TP2 AC3 Reverse Biased Diode

TP8 AC1 Forward Biased Diode

TP8 AC2 Forward Biased Diode

TP8 AC3 Forward Biased Diode

AC1 TP8 Reverse Biased Diode

AC2 TP8 Reverse Biased Diode

AC3 TP8 Reverse Biased Diode

TP8 TP2 2 Forward Biased Diodes

2. If the test reveals a failed component, replace

Main PCB 1.

L. PCB 5 Input Diode Test. (With PCB 2

removed form unit)

1. Using an ohmmeter perform the following checks:

Input Diode Module D1 on PCB 5

Test points are located on PCB 5

Meter (+) Meter (-) Indication

AC1 PMTH 1 Forward Biased Diode

AC2 PMTH 1 Forward Biased Diode

AC3 PMTH 1 Forward Biased Diode

PMTH 1 AC1 Reverse Biased Diode

PMTH 1 AC2 Reverse Biased Diode

PMTH 1 AC3 Reverse Biased Diode

PMTH 4 AC1 Forward Biased Diode

PMTH 4 AC2 Forward Biased Diode

PMTH 4 AC3 Forward Biased Diode

AC1 PMTH 4 Reverse Biased Diode

AC2 PMTH 4 Reverse Biased Diode

AC3 PMTH 4 Reverse Biased Diode

PMTH 4 PMTH 1 2 Forward Biased Diodes

2. If the test reveals a failed component, replace 40A

PCB 5.

Loading...

Loading...