CUTMASTER 40MM

SERVICE 5-16 Manual 0-5085

If gas DOES flow out of SOL1 when the unit is in SET

mode, reconnect SOL1 to the ATC connector.

4. Defective torch solenoid.

a) Measure the coil terminals of the torch mount-

ed gas solenoid SOL2 for 24VAC. If present,

replace SOL2.

5. Defective Main PCB 1.

a) Measure on Main PCB 1 between J2-20 to

GND1 for less than 2VDC.

If voltage is 12VDC replace Main PCB 1

b) Measure on Main PCB between J2-11 to GND1

for less than 2VDC. If voltage is less than

2VDC replace Main PCB 1.

6. Defective Logic PCB 3.

a) Measure on Main PCB 1 between J2-11 to

GND1 for less than 2VDC. If voltage is 12VDC,

replace Logic PCB 3.

R. Cannot adjust gas pressure.

1. Inlet gas pressure is too low

a) Increase inlet gas pressure to 95-120 psi

2. Faulty regulator.

a) Replace Regulator.

If Air flow changes but display does not:

3. Faulty Logic PCB 3.

a) Measure on Logic PCB 3 for 12 VDC between

TP3 to TP1. If voltage is low or not present,

replace Logic PCB 3.

4. Faulty Pressure transducer.

a) Measure on Logic PCB 3 between J3-2 to TP1

while adjusting the Pressure regulator from

Min to Max. Voltage should adjust from

0-4.5VDC. If voltage does not change, replace

the Pressure Transducer.

5. Faulty Logic PCB 3.

a) Measure on Logic PCB 3 between J3-2 to TP1

while adjusting the Pressure regulator from

Min to Max. Voltage should adjust from

0-4.5VDC. If voltage does change, replace the

Logic PCB 3.

S. AC LED ON, TEMP LED is OFF, GAS LED

is ON. Fan MOT 1 turns ON, plasma gas

not flowing. (Earlier revision units).

1) Open connection between J2 connector on Capaci-

tor PCB 2 to J3 connector on 40A PCB 5.

a) Check continuity.

2) Defective Main PCB 1.

a) Measure for approximately 325VDC on the

CAPACITOR PCB 2 between MTH 1 to MTH

7. Replace if no voltage present.

3) Defective Capacitor PCB 2.

a) Disconnect plug from J2 connector on Capaci-

tor PCB 2 and measure for 12VDC between

J2-1 to J2-2. If low or missing, replace PCB 2.

4) Defective 40A PCB 5.

a) Disconnect plug from J4 on 40A PCB 5. If fan

MOT 1 turns OFF, replace PCB 5.

5) Defective Main PCB 1.

a) Replace PCB 1.

5.08 Pilot Arc Problems

A. AC LED ON, TEMP LED OFF, GAS LED

ON. Nothing happens when START signal

is active. No gas flow, DC LED OFF, fans

MOT 1-3 do not turn ON.

1. Problem in the torch and leads switch circuit (or

remote pendant or CNC signal missing

a) For hand torches, check continuity of torch

switch circuit at ATC pins 3 & 4.

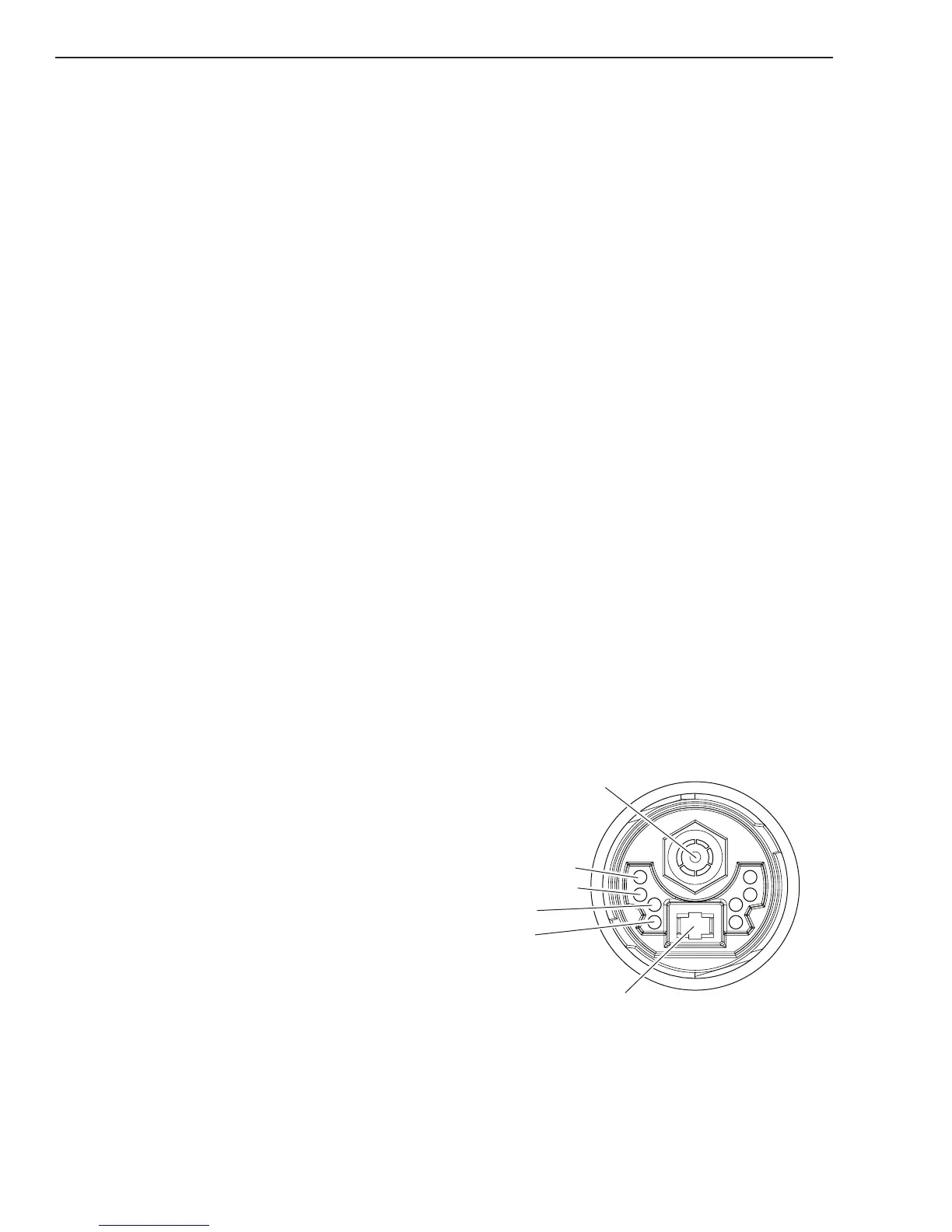

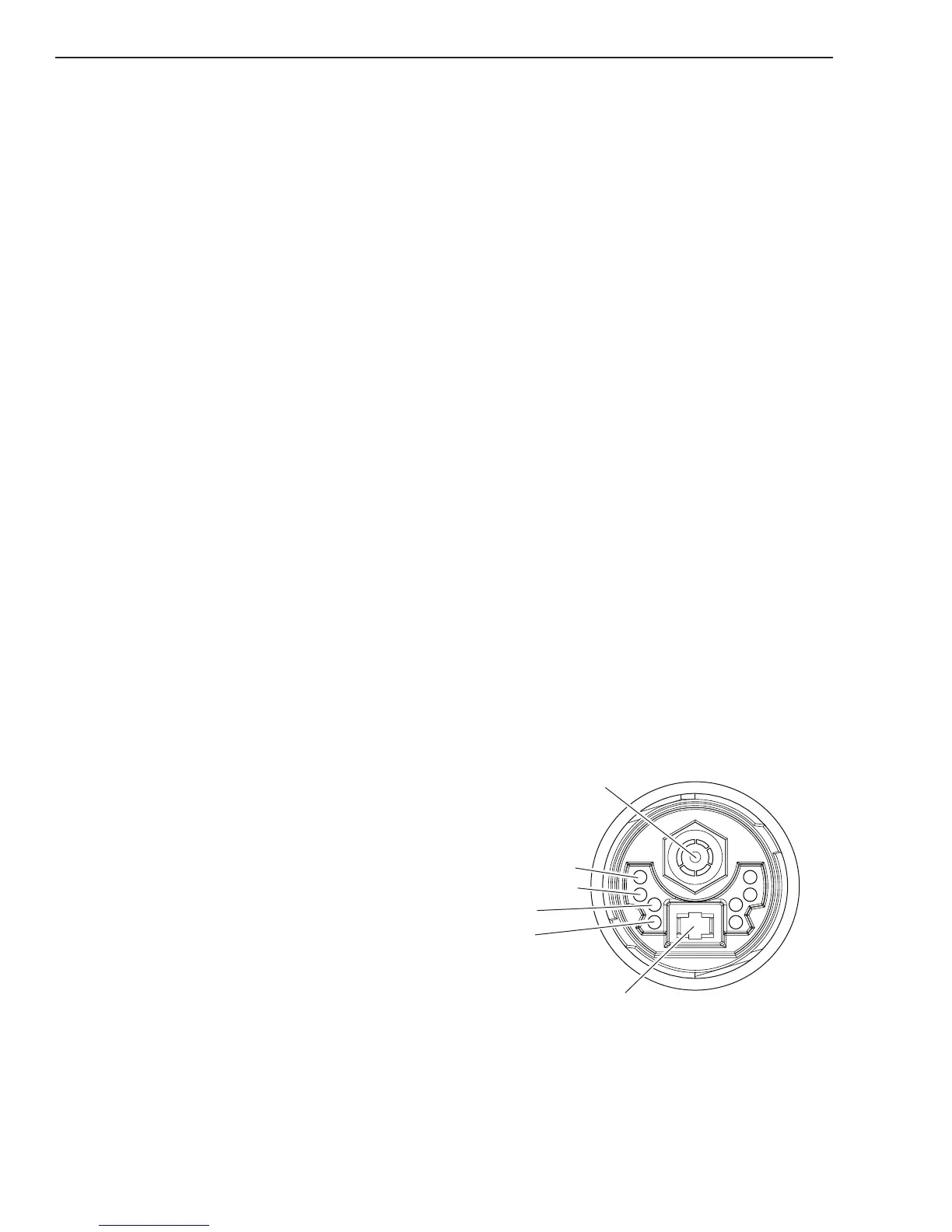

4 Torch Switch

3 Torch Switch

2 PIP

1 PIP

Pilot Lead

Art # A-08124

b) For machine torches using a remote pendant,

check continuity of Pendant switch circuit

c) Check CNC START signal

2. Defective Logic PCB 3

Loading...

Loading...