Refrigeration Service Operations

124

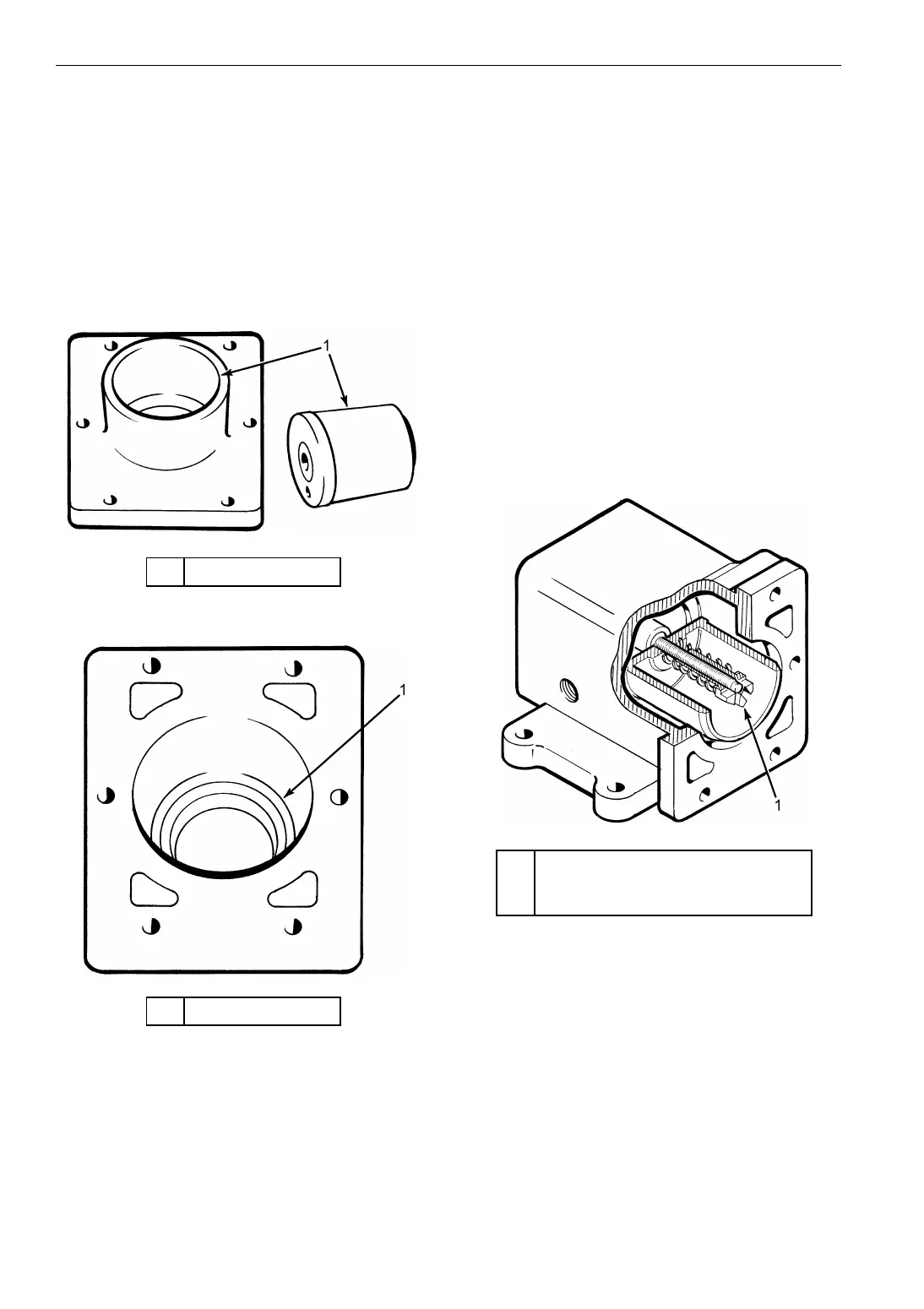

8. Inspect all the parts.

a. Piston and cap for wear (scuff marks).

b. Body for stripped threads.

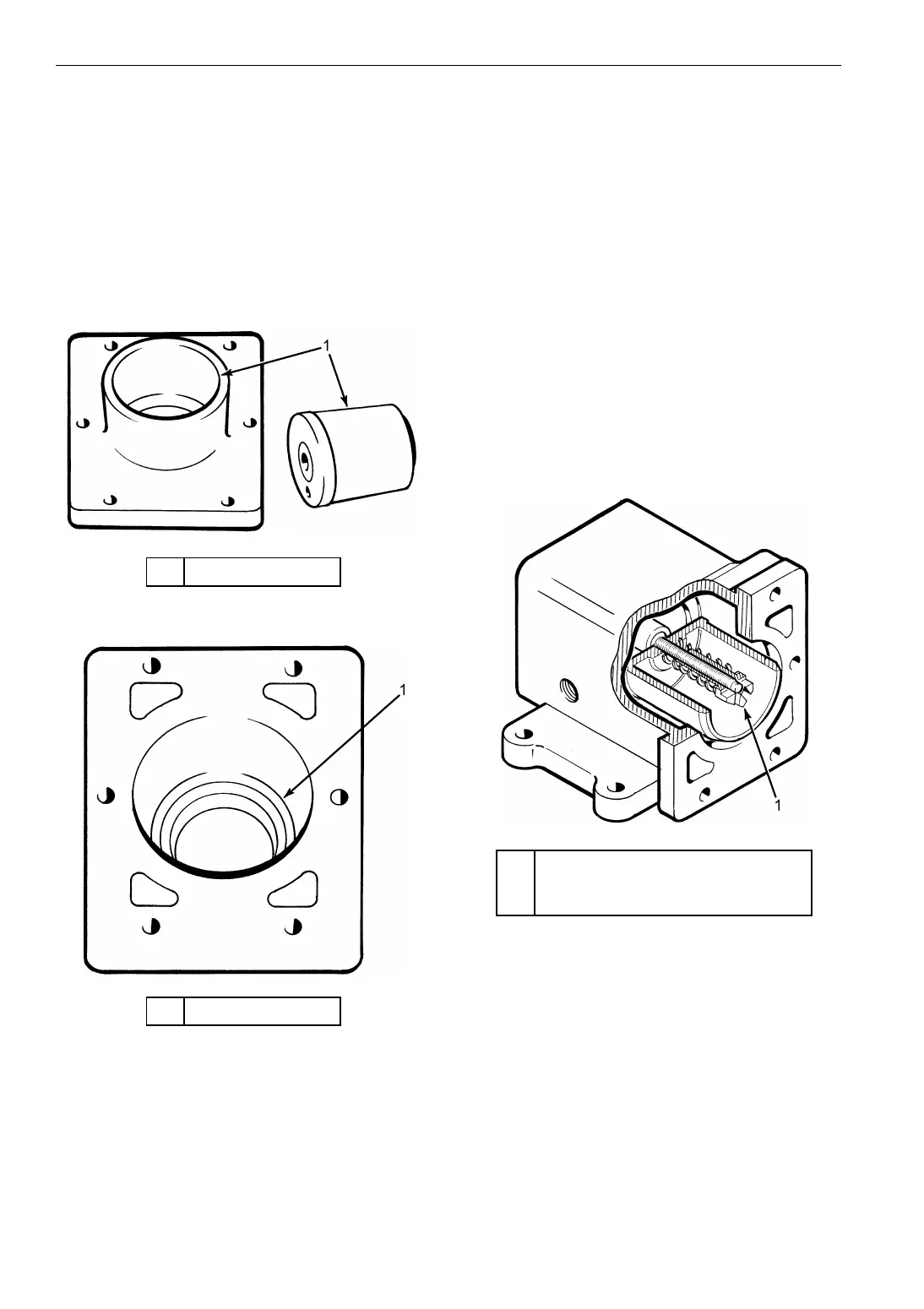

c. Bellows end cap for damage in the pilot

hole.

NOTE: The bellows is normally replaced.

4. Clean the parts that will be reused.

Reassembly

1. Install the bellows with the O-ring in the

housing.

2. Center the spring on the bellows shoulder.

3. Oil the gasket, install it on the housing, and

place the shims in the end cap (use same

number as removed). Tighten the end cap in

place with the vent hole closest to the outlet

opening of the valve housing.

4. Install the piston, spring and tighten the castle

nut until it is firmly seated against the bottom

of the piston.

5. Back off the castle nut, one full turn only.

6. Insert the cotter pin.

7. Oil the gasket and install the end cap.

8. The throttling valve will have to be

recalibrated on operating unit. (Refer to the

Specification chapter for setting.)

9. Adjust by adding or removing shims under the

spring.

1. Inspect for Wear

Figure 67: Inspect Piston and Cap for Wear

1. Inspect for Damage

Figure 68: Inspect Pilot Hole for Damage

AEA649

AEA650

1. Tighten Castle Nut to Bottom—

Then Back Off 1 Turn Only—

Insert Cotter Pin

Throttling Valve Housing Reassembly

AGA1264

Loading...

Loading...