Engine Maintenance

95

4. Remove the CYCLE-SENTRY module from

the option board to prevent the Auto Start

system from preheating and cranking the

engine.

5. Place the Diesel/Electric switch in the Diesel

position. Place the CYCLE-SENTRY switch

(if so equipped) in the Cont Run position.

6. Place the On/Off switches in the On position

and press the

ON key to energize the fuel

solenoid and the fuel pump.

7. The engine should be close to the top dead

center position with the plunger port in the

pump closed. No fuel should flow from the

drip tube.

8. Turn the engine backwards past the injection

timing mark until fuel flows from the drip

tube.

9. Slowly rotate the engine in the direction of

rotation while watching the drip tube. When

the fuel flow slows to approximately one drip

every 10 to 15 seconds, check the timing

marks. They should be lined up.

10. If the timing marks did not line up, a shim or

shims will have to be added or subtracted

from the injection pump. Adding shims will

retard the injection timing, subtracting shims

will advance the timing. Increasing or

decreasing shim thickness by 0.004 in.

(0.1 mm) will change the timing by 1 degree.

11. After shims have been added or subtracted,

recheck the timing.

12. When the injection pump has been correctly

timed to the engine, remove the pump and put

a light coat of silicone gasket sealer on the

shim pack and the pump, or dip the new shims

in lacquer thinner to activate the sealer.

13. Reinstall the pump, and torque the nuts to

18 to 20 ft-lb (24 to 27 N•m).

14. Reinstall the delivery valve spring. Torque the

delivery valve holder to 30 ft-lb (41 N•m).

15. Reinstall the injection lines, bleed the air from

the nozzles, and test run the engine.

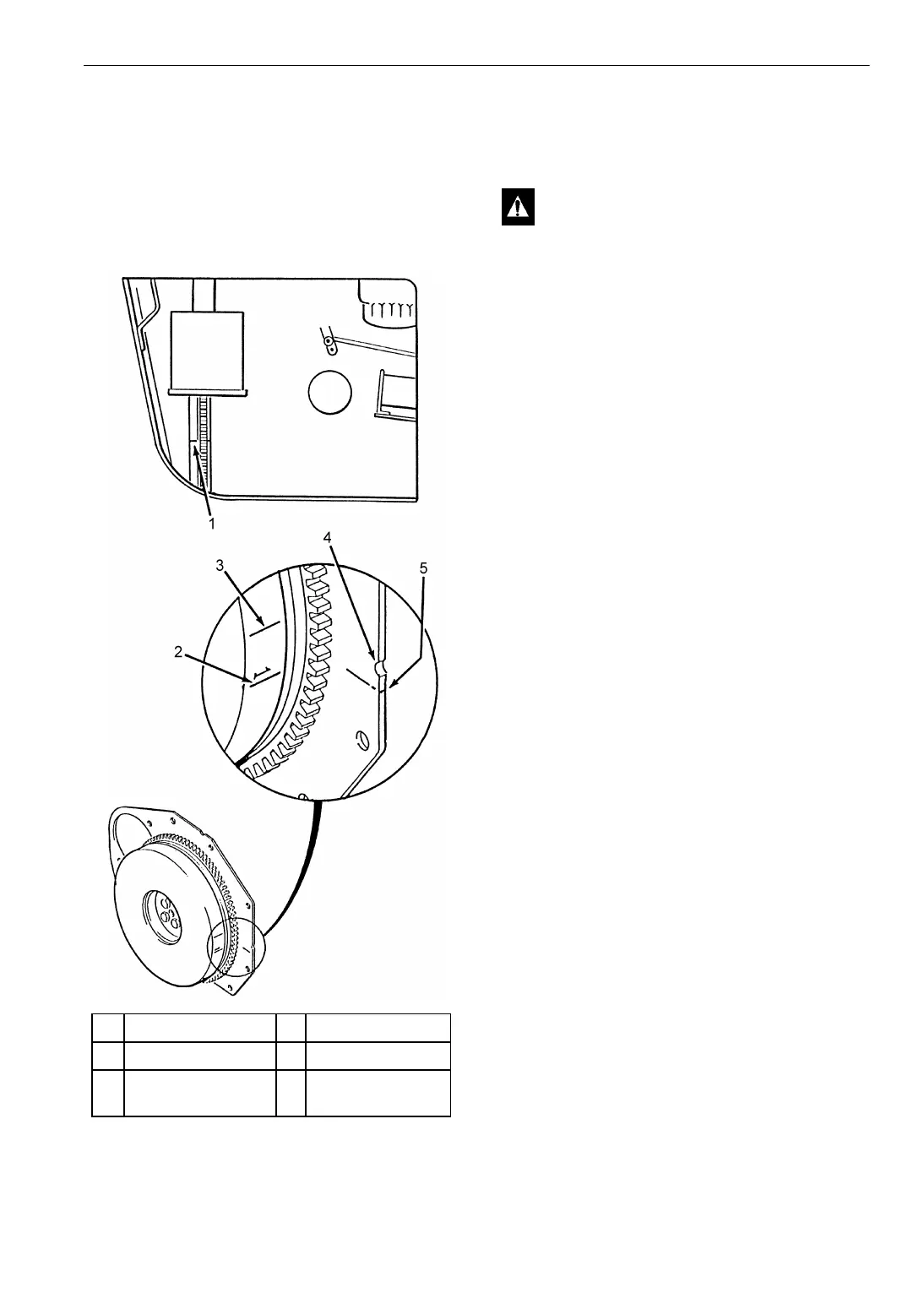

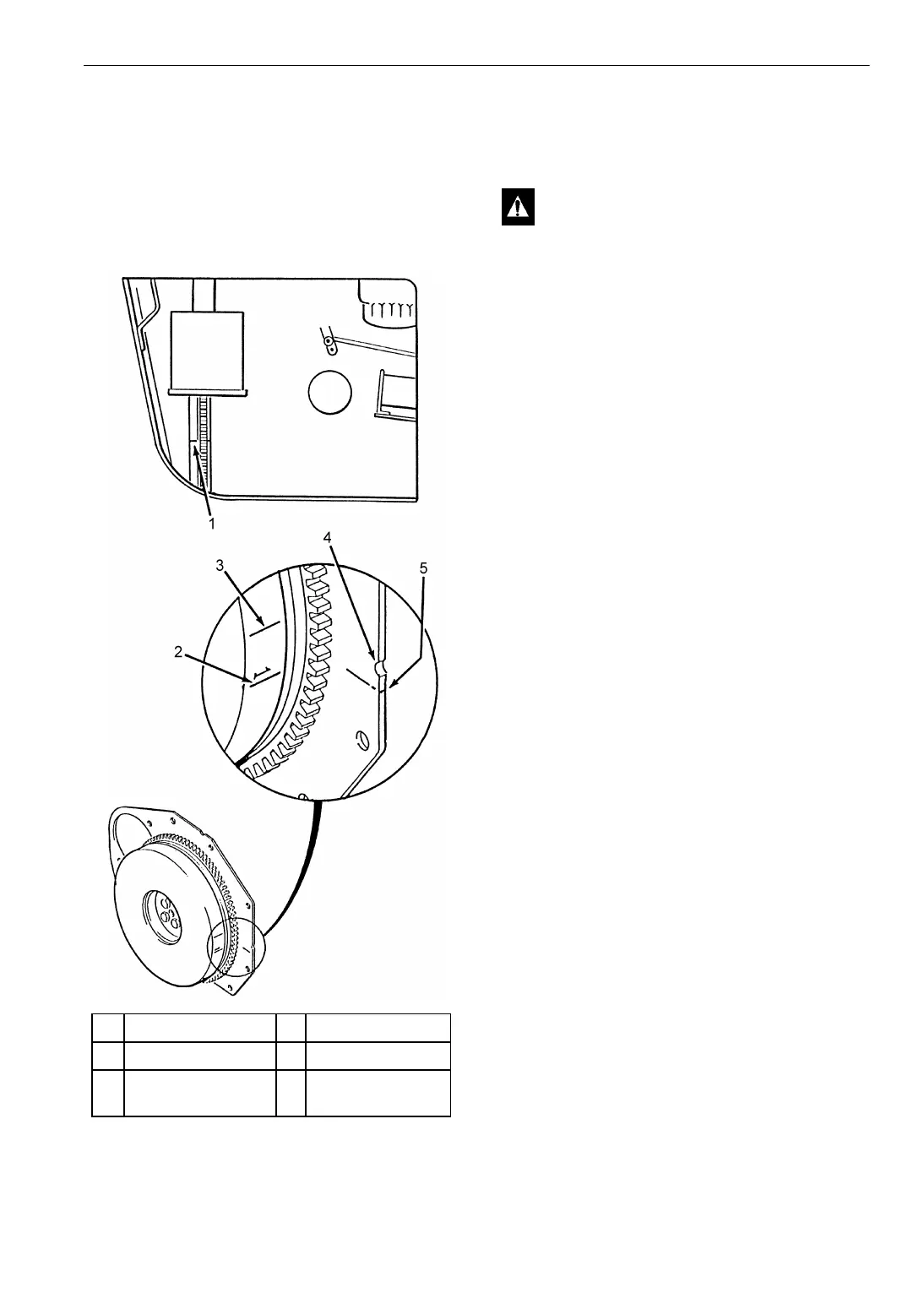

1. Timing Mark 4. Round Notch

2. TDC Mark 5. File V-Notch Here

3. Injection Timing

Mark

Figure 48: Timing Marks

AEA637

CAUTION: Loosen the injection line at

the injection nozzle for the number 2

cylinder to prevent any possibility of the

engine firing.

Loading...

Loading...