Electrical Maintenance

67

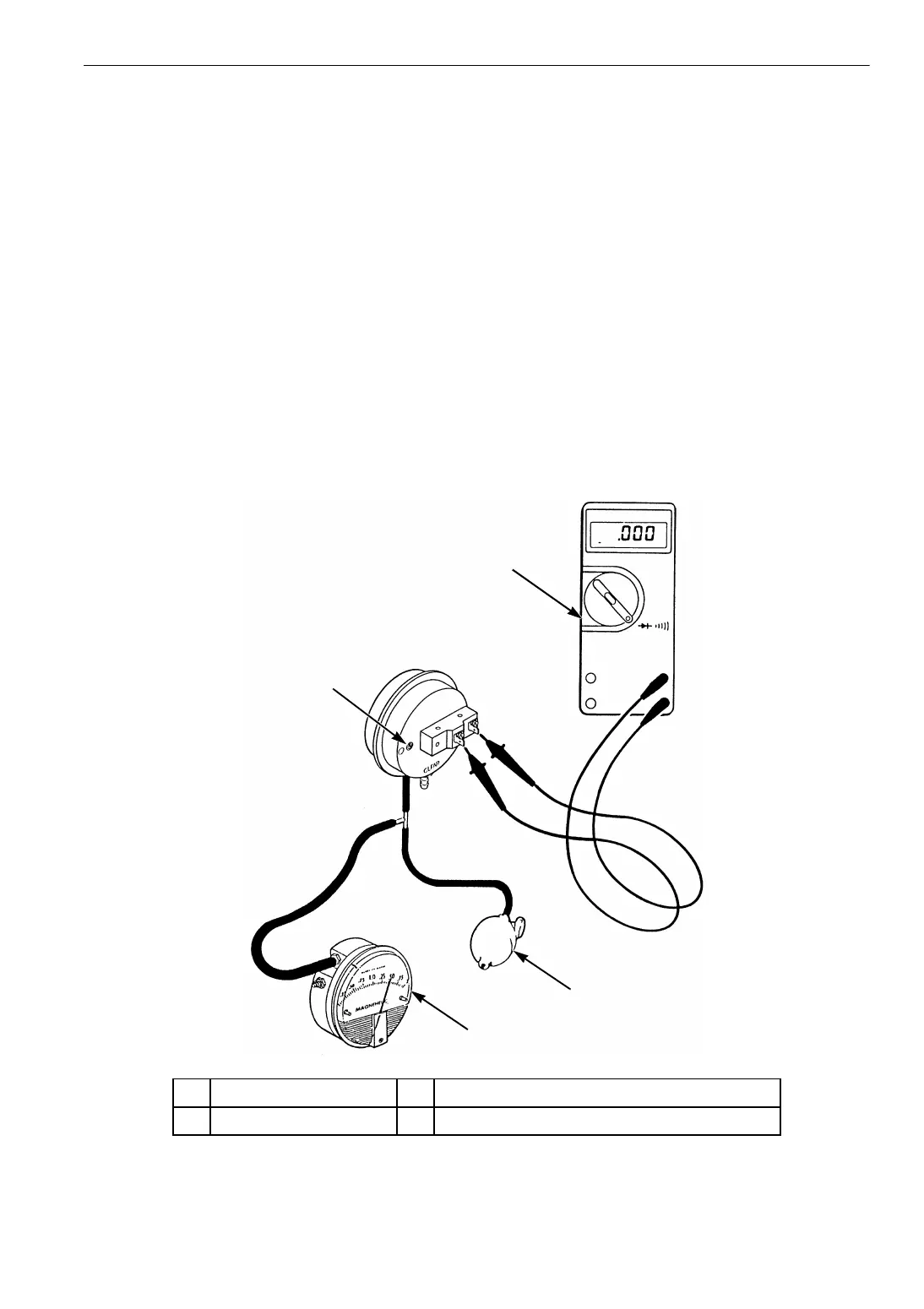

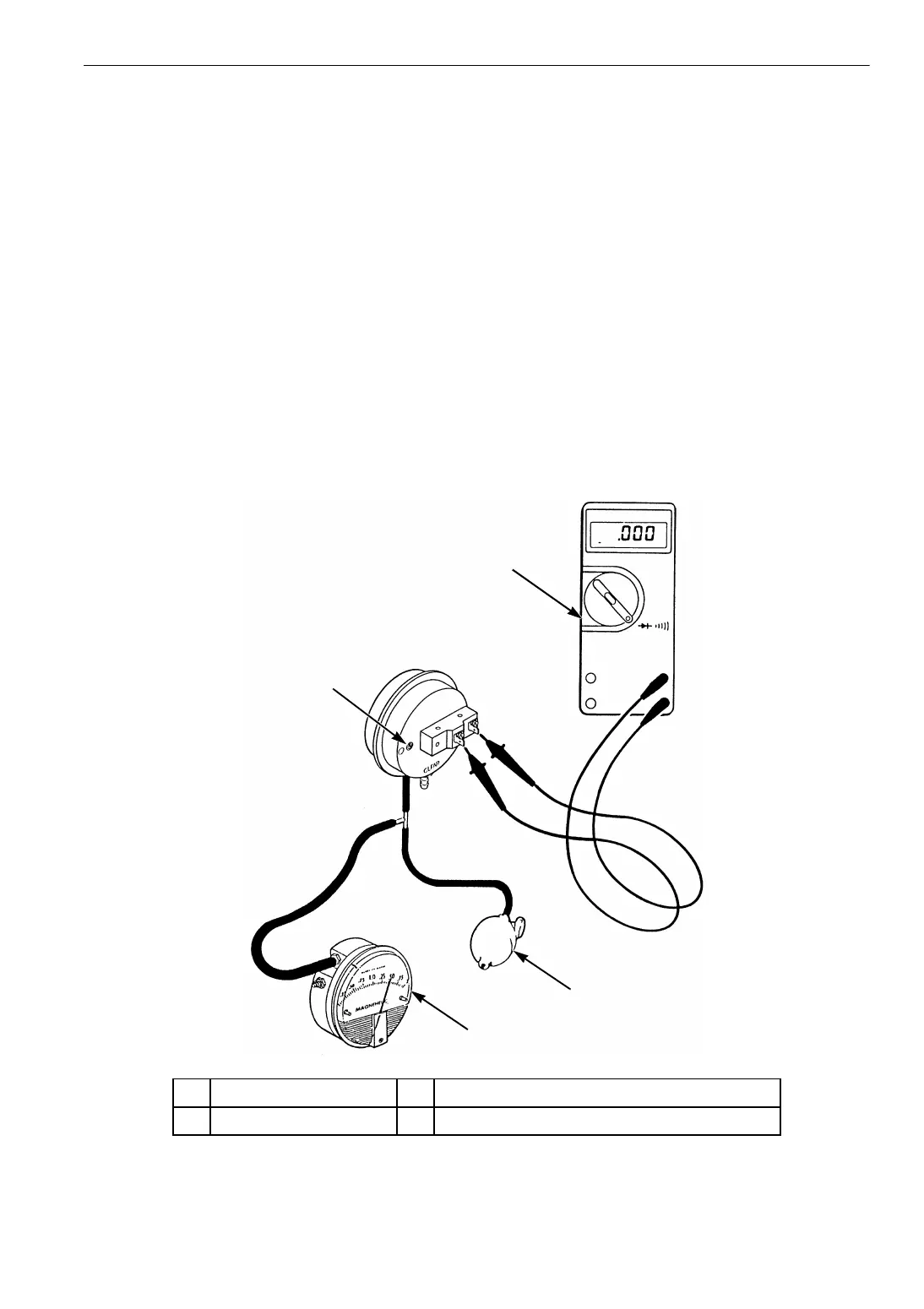

2. Disconnect one wire at the switch terminal.

Connect a test light or continuity tester to the

two terminals used on the switch.

3. Connect the test equipment (P/N 204-442 and

P/N 204-494) to the hose fitting on the side of

the air switch stamped BLACK.

4. Pressurize the hose until the continuity tester

indicates a completed circuit. Now read the

dial of the test gauge. This is the setpoint of

the air switch. The correct settings is

1.00 ± 0.05 in. (25.4 ± 1.3 mm) H

2

O. Release

the pressure.

5. If the switch is out of calibration, pressurize

the hose again until the tester indicates the

correct reading. Turn the adjustment screw

until the switch closes and the continuity

tester indicates a completed circuit with the

correct reading. Release the pressure.

6. Repeat the test procedure several times to be

sure the setting is correct.

7. Remove the test equipment. Connect the wire

and air sensing tubes to the switch. The

BLACK hose from the high pressure or air

inlet side of the evaporator coil goes on the

hose fitting on the side of the air switch

stamped BLACK. The CLEAR hose from the

low pressure or air outlet side of the

evaporator coil goes on the hose fitting on the

side of the air switch stamped CLEAR.

NOTE: Route hoses for continuous slope to

avoid condensate traps.

AGA271

1

2

3

4

1. Adjustment Screw 3. Squeeze Bulb (P/N 204-494)

2. Continuity Tester 4. Pressure in Inches of Water (P/N 204-442)

Figure 22: Air Switch Testing and Adjustment

Loading...

Loading...