Engine Maintenance

90

Troubleshooting the Fuel Solenoid

System

NOTE: The fuel solenoid pull-in coil may

require 18 to 25 amps to turn on the fuel. The

unit’s battery must be in good condition. If the

battery has enough power to crank the engine

over, it has enough power to energize the fuel

solenoid pull-in coil.

If you suspect that the engine does not run

because the fuel solenoid is not operating

correctly, use the following procedure:

1. Disconnect the 20 wire from the reset switch

so the reset switch will not trip.

2. Disconnect the fuel solenoid wire connector

from the main wire harness.

3. Remove the CYCLE-SENTRY module from

the option board to prevent the Auto Start

system from preheating and cranking the

engine.

4. Place the Diesel/Electric switch in the Diesel

position. Place the CYCLE-SENTRY switch

(if so equipped) in the Cont Run position.

5. Place the On/Off switches in the On position

and press the

ON key to turn the unit On.

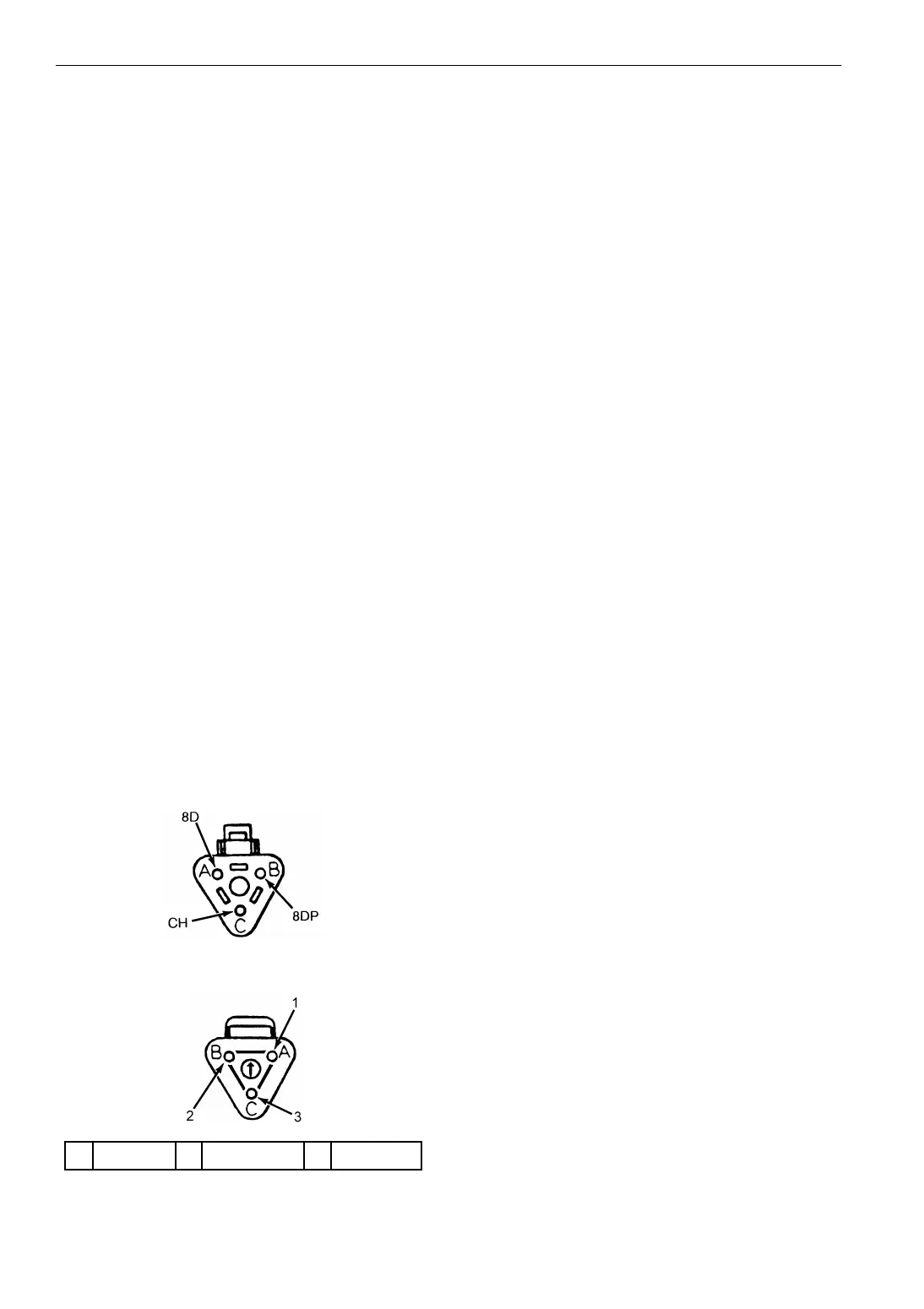

6. Check the voltage on the 8D circuit (pin A) in

the main wire harness connector for the fuel

solenoid. Refer to the following illustrations

to identify the pins in the wire connectors.

Figure 43: Main Wire Harness Connector Pin

a. If battery voltage is not present on the 8D

circuit, check the 8D circuit and the

related circuits and components for a fault.

b. If battery voltage is present on the 8D

circuit, go to step 7.

7. Check the CH circuit (pin C) in the main wire

harness at the fuel solenoid connector for

continuity to a good chassis ground.

a. If there is no continuity between the CH

circuit and a good chassis ground, check

the CH wire for an open circuit.

b. If there is continuity between the CH

circuit in the main wire harness at the fuel

solenoid wire connector and a good

chassis ground, go to step 8.

8. Place a jumper wire between the black wire

(CH—pin C) in the fuel solenoid connector

and a good chassis ground.

9. Test the pull-in coil by momentarily placing a

jumper between the white wire (8DP—pin B)

in the fuel solenoid connector and the 2

terminal at the control circuit. The fuel

solenoid should make a definite click when

the pull-in coil is energized and should click

again when the pull-in coil is de-energized.

NOTE: The pull-in coil will draw 18 to 25

amps so do not leave the jumper connected to

the white wire (8DP—pin B) for more than a

few seconds.

a. If the pull-in coil does not energize, check

the resistance of the pull-in coil by placing

an ohmmeter between the white wire

(8DP—pin B) and the black wire (CH—

pin C) in the fuel solenoid connector. The

resistance of the pull-in coil should be 0.5

to 0.7 ohms. If the resistance of the pull-in

coil is not in this range, replace the fuel

solenoid.

NOTE: If the pull-in coil fails, make sure to

replace the fuel solenoid relay with a Potter

& Brumfield relay (P/N 44-9111).

b. If the pull-in coil does energize, go to step

10.

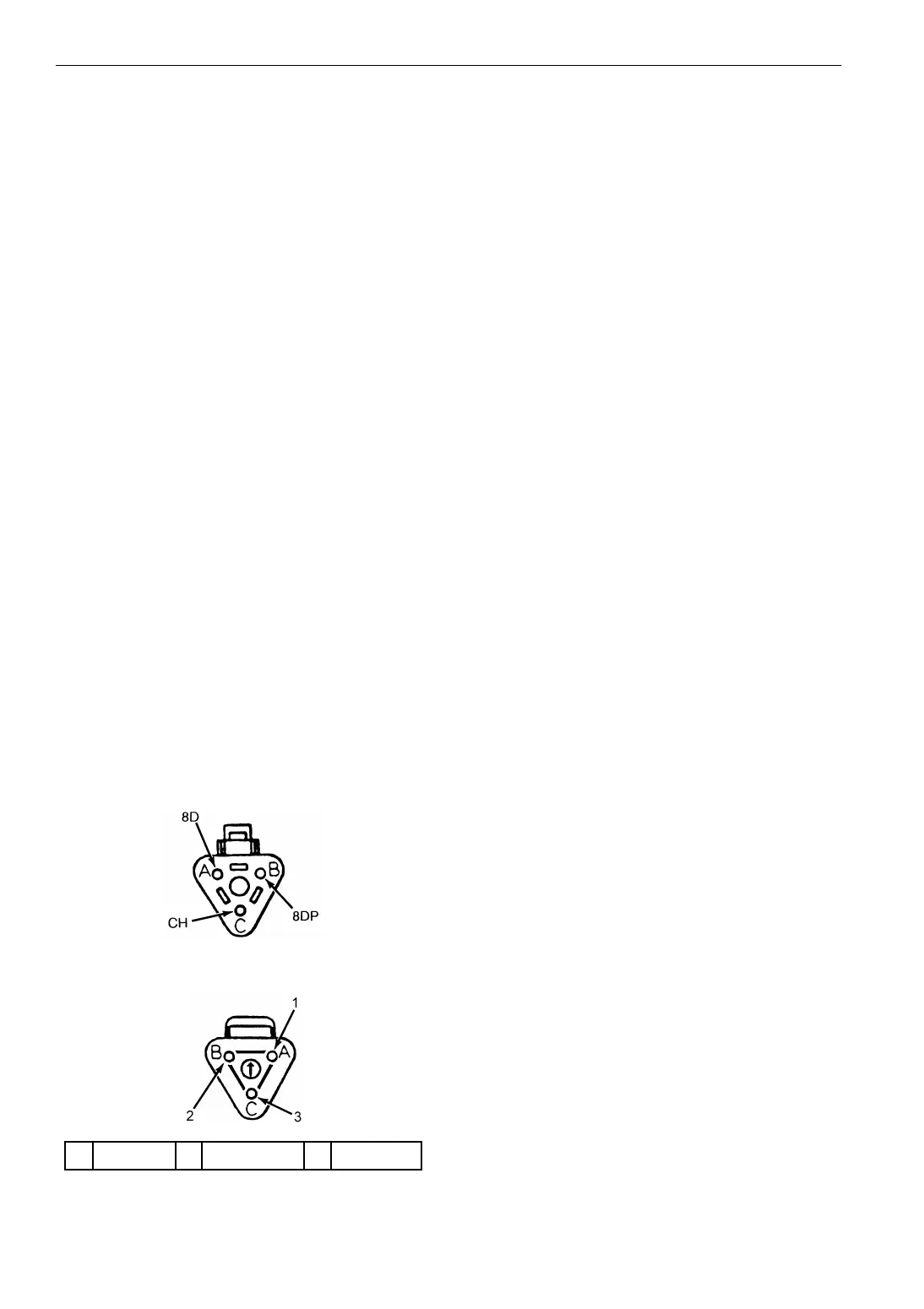

1. Red (8D) 2. White (8DP) 3. Black (CH)

Figure 44: Fuel Solenoid Connector Pin

AEA633

Loading...

Loading...