Engine Maintenance

92

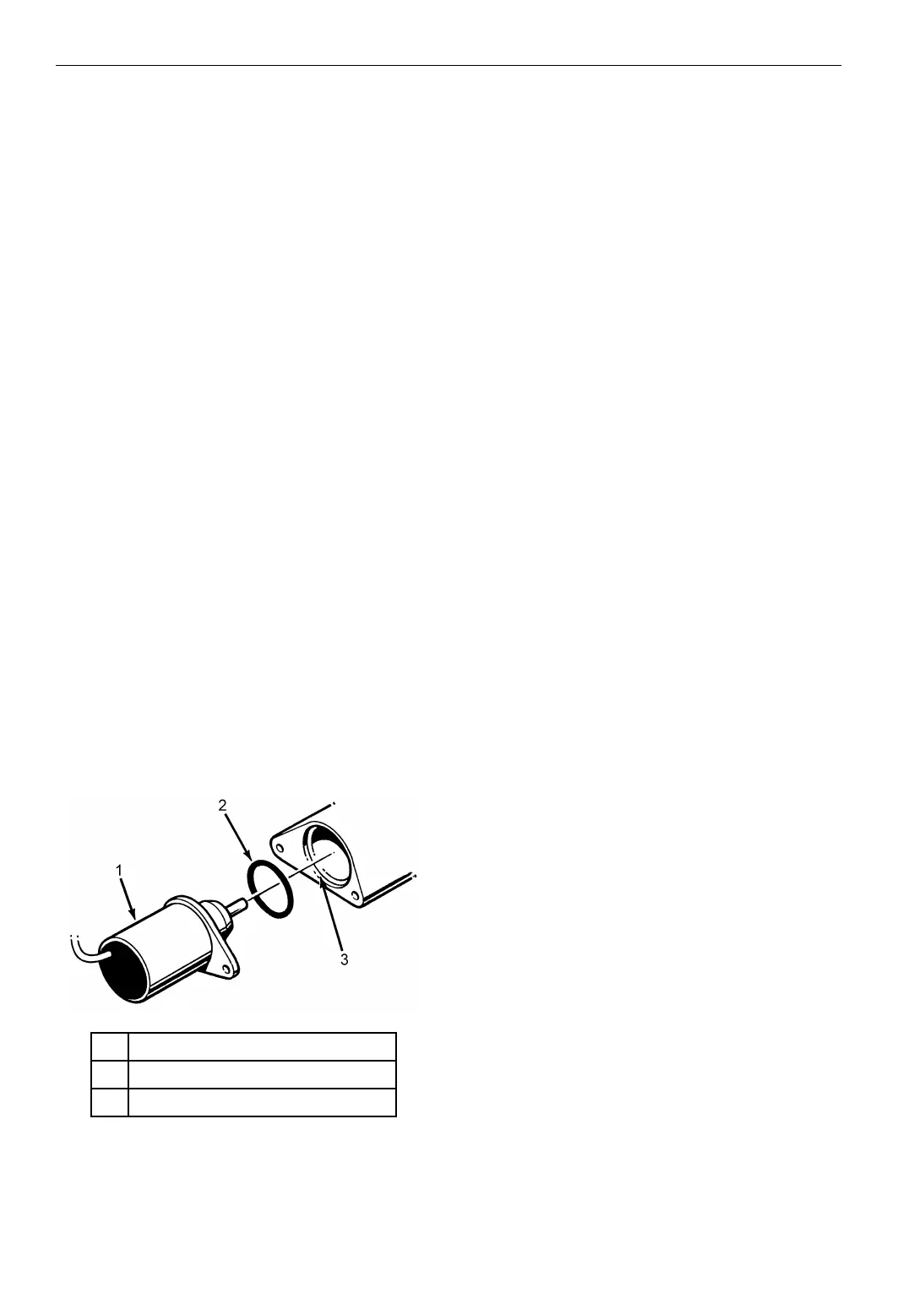

Fuel Solenoid Replacement

1. Disconnect the 20 wire from the reset switch

to prevent the reset switch from tripping.

2. Connect the new fuel solenoid wire connector

to the main wire harness.

3. Remove the CYCLE-SENTRY module from

the option board to prevent the Auto Start

system from preheating and cranking the

engine.

4. Place the Diesel/Electric switch in the Diesel

position. Place the CYCLE-SENTRY switch

(if so equipped) in the Cont Run position.

5. Place the On/Off switches in the On position

and press the

ON key to energize the fuel

solenoid.

NOTE: The fuel solenoid must be energized

when it is being installed. If it is not, the plunger

and the linkage may not line up correctly and the

fuel solenoid will not function properly.

6. Place the o-ring in the groove in the end of the

fuel injection pump. Make sure that the o-ring

is positioned correctly during installation to

avoid damage and leaks.

7. Install the new fuel solenoid.

8. Press the

OFF key, replace the

CYCLE-SENTRY module, and reconnect the

20 wire to the reset switch.

Engine Speed Adjustments

When the diesel engine fails to maintain the

correct engine speeds, check the following before

adjusting the speed:

1. Bleed air out of the fuel system. Recheck the

speed.

2. Bleed air out of the nozzles. Recheck the

speed.

3. Check the operation of the electric fuel pump.

Make engine speed adjustments with the engine

fully warmed up.

Low Speed Adjustment

1. Start the unit and let it run until the engine is

warmed up.

2. Set the thermostat to make the engine run in

low speed and check the engine speed. The

engine speed should be 1600 to 1650 RPM.

3. If the engine speed is not correct, loosen the

jam nut on the low speed adjustment screw.

4. Turn the low speed adjustment screw to

change the engine speed. Turn the screw in to

increase the engine speed. Turn the screw out

to decrease the engine speed.

5. Set the engine speed at 1600 to 1650 RPM and

tighten the jam nut.

High Speed Adjustment

1. Start the unit and let it run until the engine is

warmed up.

2. Set the thermostat to make the engine run in

high speed and check the engine speed. The

engine speed should be 2400 to 2450 RPM.

3. If the engine speed is not correct, loosen the

jam nut, remove the clip from the solenoid

rod, and remove the solenoid rod from the eye

bolt.

1. Fuel Solenoid

2. O-ring

3. Groove in Fuel Injection Pump

Figure 46: Fuel Solenoid Components

AEA635

Loading...

Loading...