Machine Calibration

X63/X62 Installation and Calibration Manual

3-26

Dog-bone Sensor Calibration

The dog-bone sensor calibration requires both the pitch and the roll

calibration. When performing the dog-bone sensor calibration,

builder’s level is required to correctly position the dog-bone at zero

degrees.

1. Position the machine on a stable surface free of obstructions and

rotate the body parallel to the tracks.

2. In 3DMC, tap Topcon LogoControl Machine setup, select

the applicable machine file for the job, and press Edit.

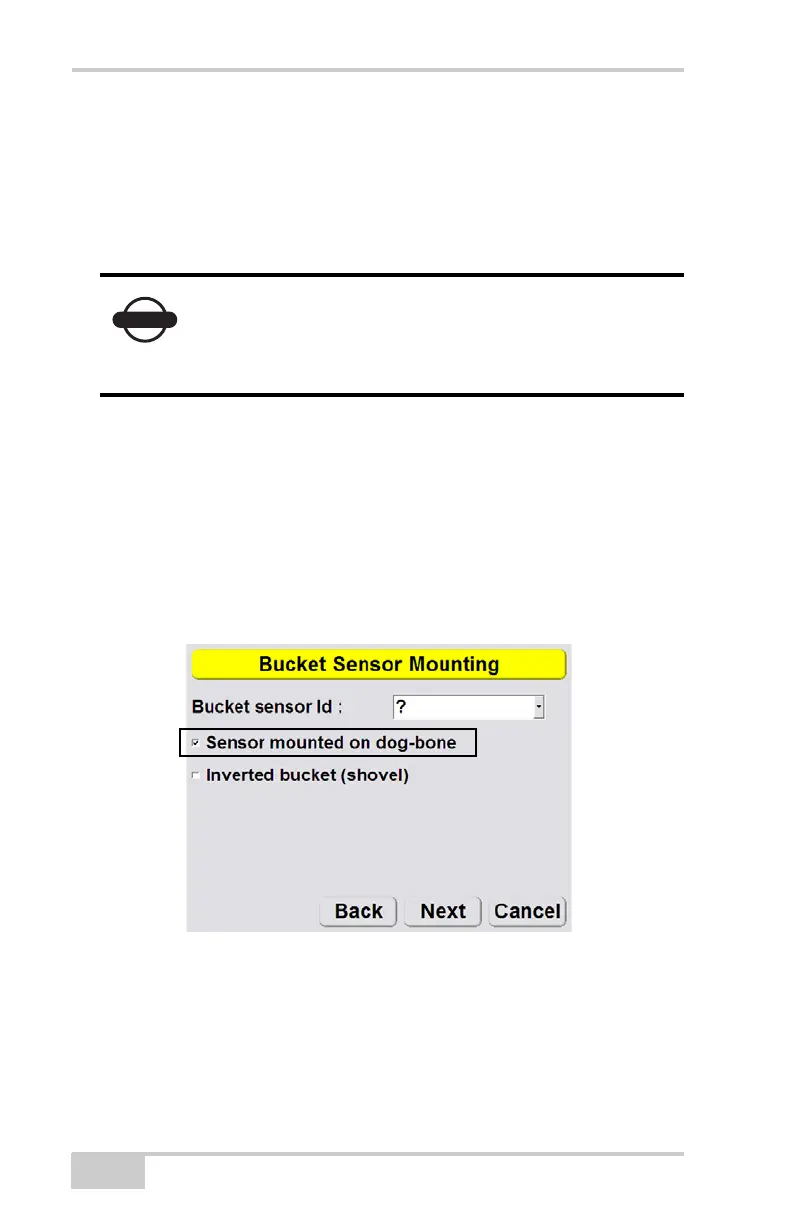

3. Press Next to navigate to the Bucket Sensor Mounting screen.

4. Check the Sensor mounted on dog-bone check box, and tap Next

(Figure 3-26 on page 3-26).

Figure 3-26. Check Sensor Mounted on Dog-bone.

The dog-bone calibration compares the stick sensor

to the dog-bone sensor to determine bucket angle.

The stick sensor must be properly calibrated before

attempting the dog-bone calibration.

Loading...

Loading...