1: SAFETY

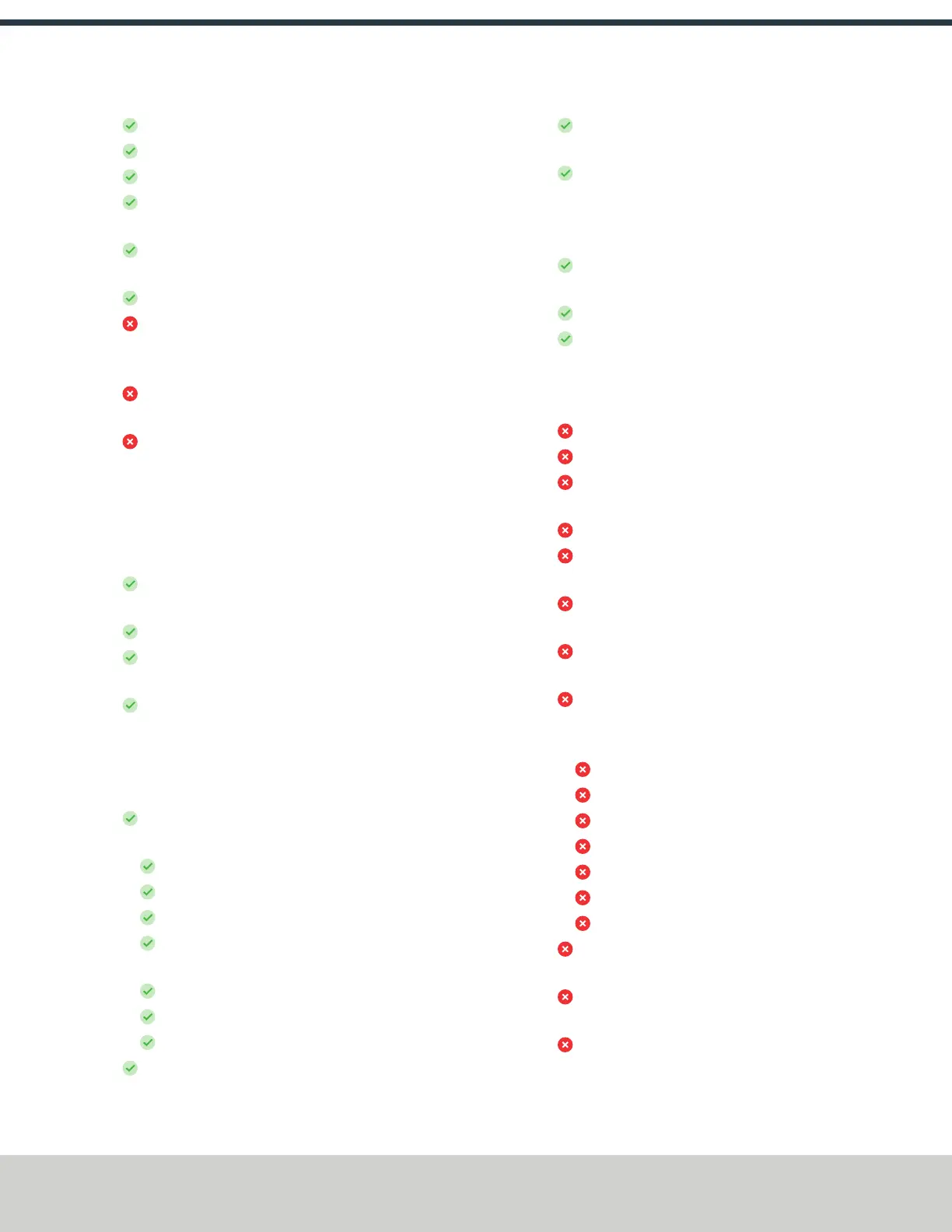

Tie up long hair and secure it under a hat.

Wear safety eye protection rated for ANSI Z87+.

Wear closed-toed safety shoes.

Wear ear protection when you expect the machine or the

machining processes to exceed safe exposure limits.

Keep the work area clean and free of clutter. Machine

motion can occur if controls are accidentally activated.

Immediately clean up spills after they occur.

Never operate the machine after consuming alcohol or

taking medication that could prevent you from safely

operating the machine.

Never operate the machine while tired or otherwise

impaired.

Never operate the machine in an explosive (ATEX)

atmosphere. Such explosive atmospheres include

explosive gases, vapors, mists, powders, and dusts.

1.4.2 Operational Safety

General

Understand that the machine is automatically controlled

and can start at any time.

Become familiar with all physical and software controls.

Always use a chip scraper or brush when clearing away

chips, oil, or coolant.

Examine all tools, fixtures, workpieces, and guarding for

signs of damage. Replace any damaged components as

soon as you find them.

The enclosure and other guards may not stop all types of

projectiles, like broken tools or loose workpieces.

Stop the machine and verify that all machine motion has

completely stopped before doing any of the following:

Adjusting a part, fixture, or coolant nozzle.

Changing tools or parts.

Clearing away chips, oil, or coolant.

Reaching into any part of the machine's motion

envelope.

Removing protective shields or safeguards.

Taking measurements.

Doing any other action inside the machine enclosure.

Use flood or MQL (mist) coolant as required by the

machining operation.

Only use coolants designed for metal working applications

such as soluble oils, semi-synthetic, or synthetic coolants.

Read the Safety Data Sheet (SDS) for all workpiece

materials, coatings, coolants (flood or MQL), lubricants,

and other consumables. Chips, dust, and vapors from

certain materials can be toxic or otherwise harmful.

Dispose of scrap and swarf according to local regulations

and guidelines.

Thoroughly read all safety precautions and instructions.

When machining an unproven program, use feed, speed,

and maximum velocity overrides, Distance-to-Go (DTG)

displays, single block, feed hold, and other control

features.

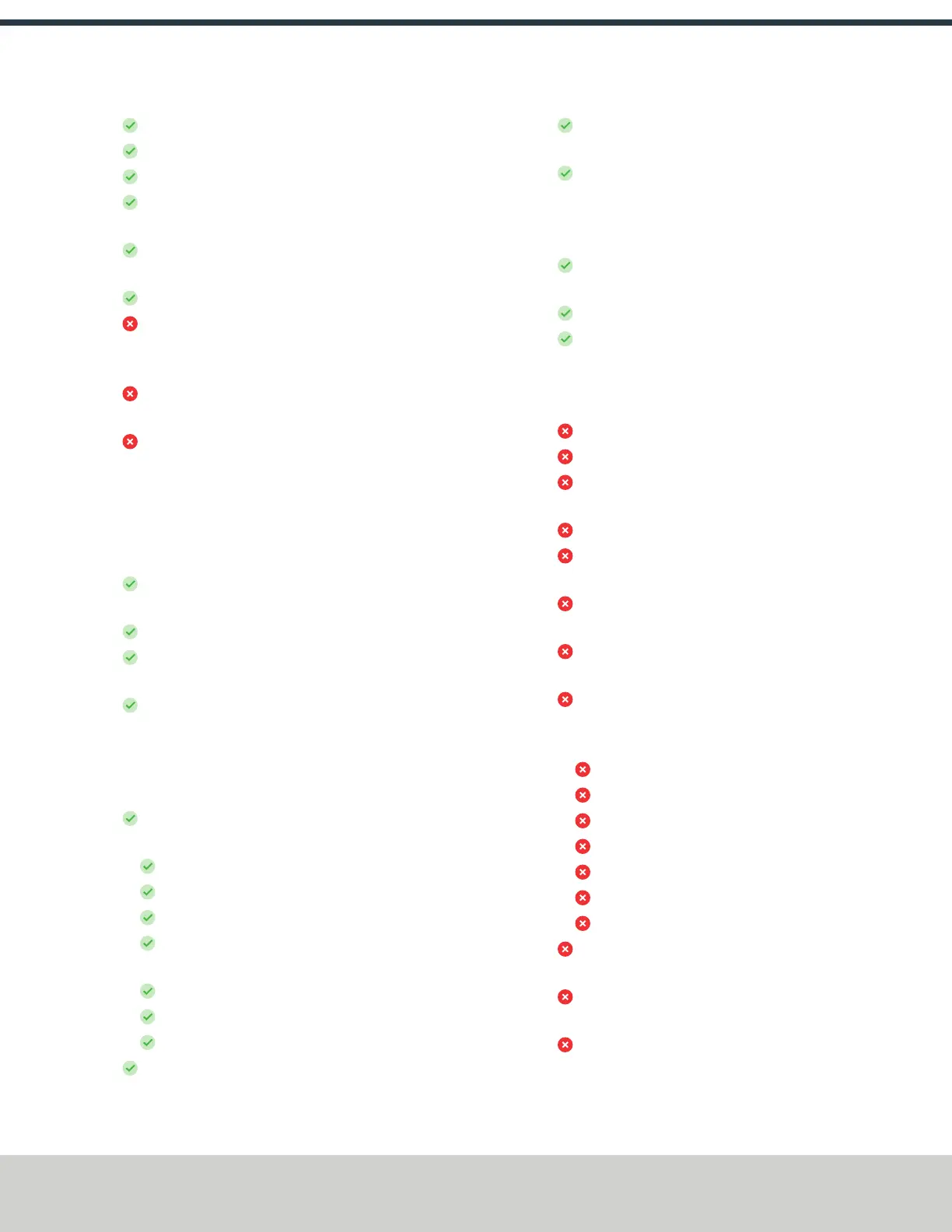

Never enter the machining envelope.

Never reach around a guard.

Never allow the machine to run with the enclosure door

open.

Never allow the machine to run unattended.

Never obstruct the Emergency Stop button or any other

controls.

Never allow untrained operators to install, operate, or

maintain the machine.

Never modify, defeat, or bypass safety devices or

interlocks.

Never machine abrasive, carcinogenic, explosive,

flammable, radioactive, or toxic materials. Such materials

include, but are not limited to:

Beryllium and its alloys

Ceramic

Fiberglass

G10 fiberglass laminate

Graphite

Lead and its alloys

Magnesium and its alloys

Never allow swarf to accumulate on or within the

machine.

Never use flammable liquids (like alcohol, diesel fuel, or

kerosene) in the machine’s coolant system.

Never use water, coolants without rust inhibitors, or

straight cutting oil in the machine’s coolant system.

©Tormach® 2021

Specifications subject to change without notice.

Page 15 UM10753: 8L Operator's Manual (Version 0321B)

For the most recent version, see tormach.com/support

Loading...

Loading...