Work Offset Naming

10 G54.1 P10 Not used

11 G54.1 P11 Not used

...

499 G54.1 P499 Not used

500 G54.1 P500 Not used

6.9 SET TOOL GEOMETRY OFFSETS

Before running a G-code program, PathPilot must know the

geometry of the tools that are required for the program. For

more information on using tool length offsets, see "About Tool

Offsets" (on the next page).

Note: You can import a .csv file with tool geometry

offset data. For information, see "Import and Export

the Tool Table" (on the next page).

To set tool geometry offsets:

1. Verify that the machine is powered on, out of reset, and

the axes have been referenced.

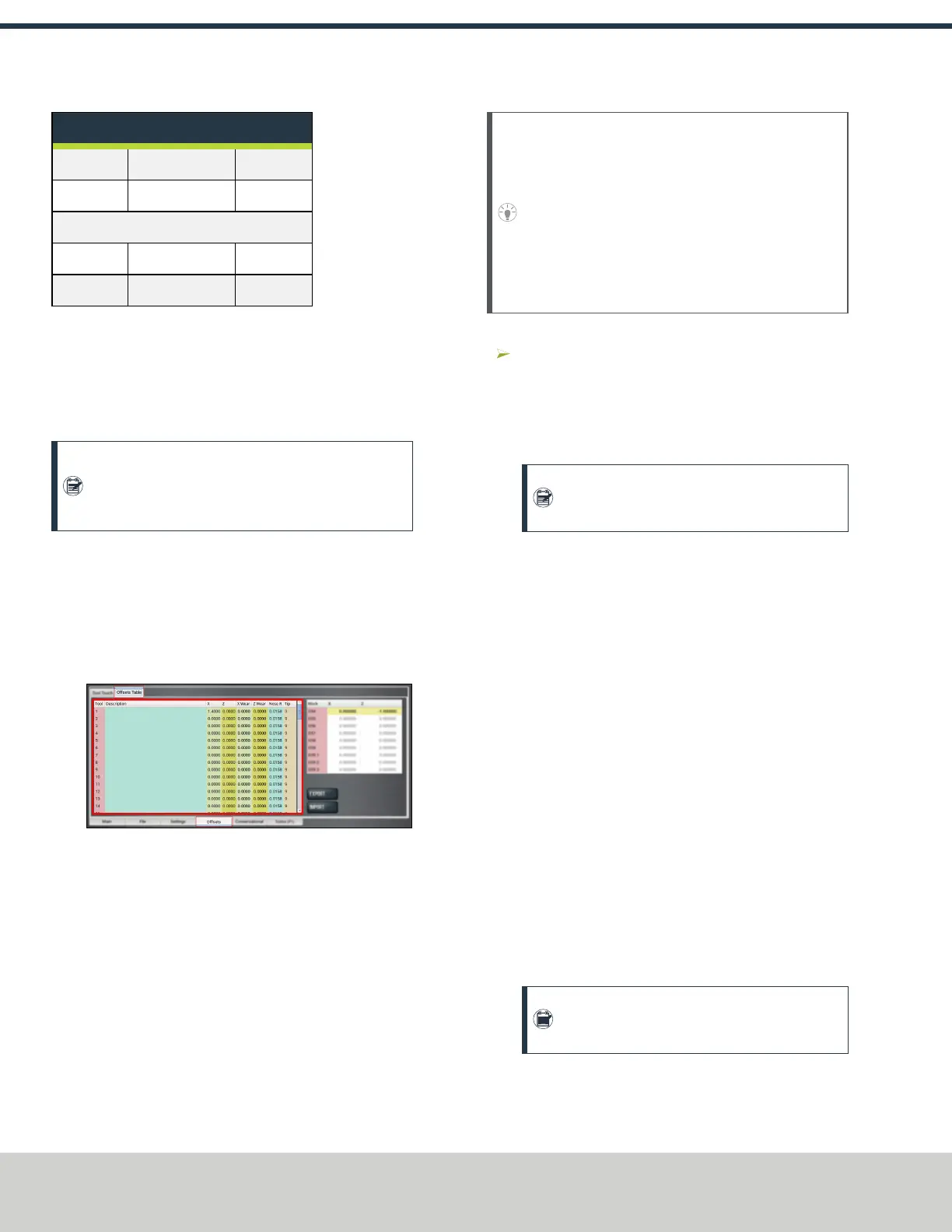

2. From the PathPilot controller, on the Offsets tab, select

the Offsets Table tab.

3. Find the Tool Table window.

Figure 6-16: Tool Table window on the Offsets tab.

4. Touch off the tool geometry offsets. For information, see

"Touch Off the Tool Geometry Offsets" (below).

5. (Optional) Select a field to edit. When finished, select

the Enter key.

6.9.1 Touch Off the Tool Geometry Offsets

On the Offsets tab, you can use the Tool Touch tab to

graphically select a tool, and then touch off the tool to set the

geometry offsets.

Tip! When using this method to measure your tool

geometry, remember that the X zero location never

changes (the spindle centerline is always X = 0), but

the Z zero location may change depending on the

length of the workpiece that is chucked into the

spindle. As long as each tool is measured to a face

that has been zeroed, only measure these tools one

time or until you replace an insert.

To touch off the tool geometry offsets:

From the Offsets tab, on the Tool Touch tab, select a

tool.

The tools along the bottom of the screen are front tool

post tools (used by machines with a quick-change tool

post setup).

Note: Gang tooling setups typically use both

front and rear tool post tools.

After you select the tool, PathPilot:

o

Sets the tip orientation for the tool, used (along with

tip radius) in cutter compensation.

o

Sets the tool type (front tool post or rear tool post),

used by the conversational routines to double check

the user entry fields in an attempt to try to detect and

prevent crashes.

o

Displays the tool touch off dialog.

Touch X

1. Take a skim cut off of the diameter of the workpiece —

just long enough to measure the cut surface with a

micrometer.

2. Jog the tool away from workpiece in Z, but don't jog the

machine in X.

3. Measure the diameter of the skim-cut workpiece with a

micrometer.

4. In the Touch XDROfield, type the value that you

measured in Step 3.

Note: If you're touching off a front tool post

tool, verify that the value you enter is negative.

5. Select Touch X.

The LEDcomes on.

©Tormach® 2021

Specifications subject to change without notice.

Page 50 UM10753: 8L Operator's Manual (Version 0321B)

For the most recent version, see tormach.com/support

6: BASIC OPERATIONS

Loading...

Loading...