TPT Wirebonder www.tpt.de Page 8 of 53 September 2016

7. Basic Ultrasonic Bonding & Bond Modes

All TPT Bonders utilize the basic ultrasonic bonding method. Bonding two types of metals using the ultrasonic

method results from three variables: force, ultrasonic power and time. If the HB16 is used for gold wire bonding,

heat is used as a fourth variable. At this point these parameters will be explained briefly. The outcome of altering

the variables will be explained in the referenced chapters.

The force supports the plastic deformation and facilitates the coupling between the bonding tool, the wire

and the substrate.

The scrubbing effect of Ultrasonic (63,3kHz) displaces the contaminants on the surface and ensures metal

to metal coupling. When using the Ballbond or Ball Bump option, altering the Ultrasonic also changes the

size of the ball.

The time has to be set sufficiently long to cause solid state diffusion.

The heat support the ultrasonic. With more heat is less ultrasonic necessary.

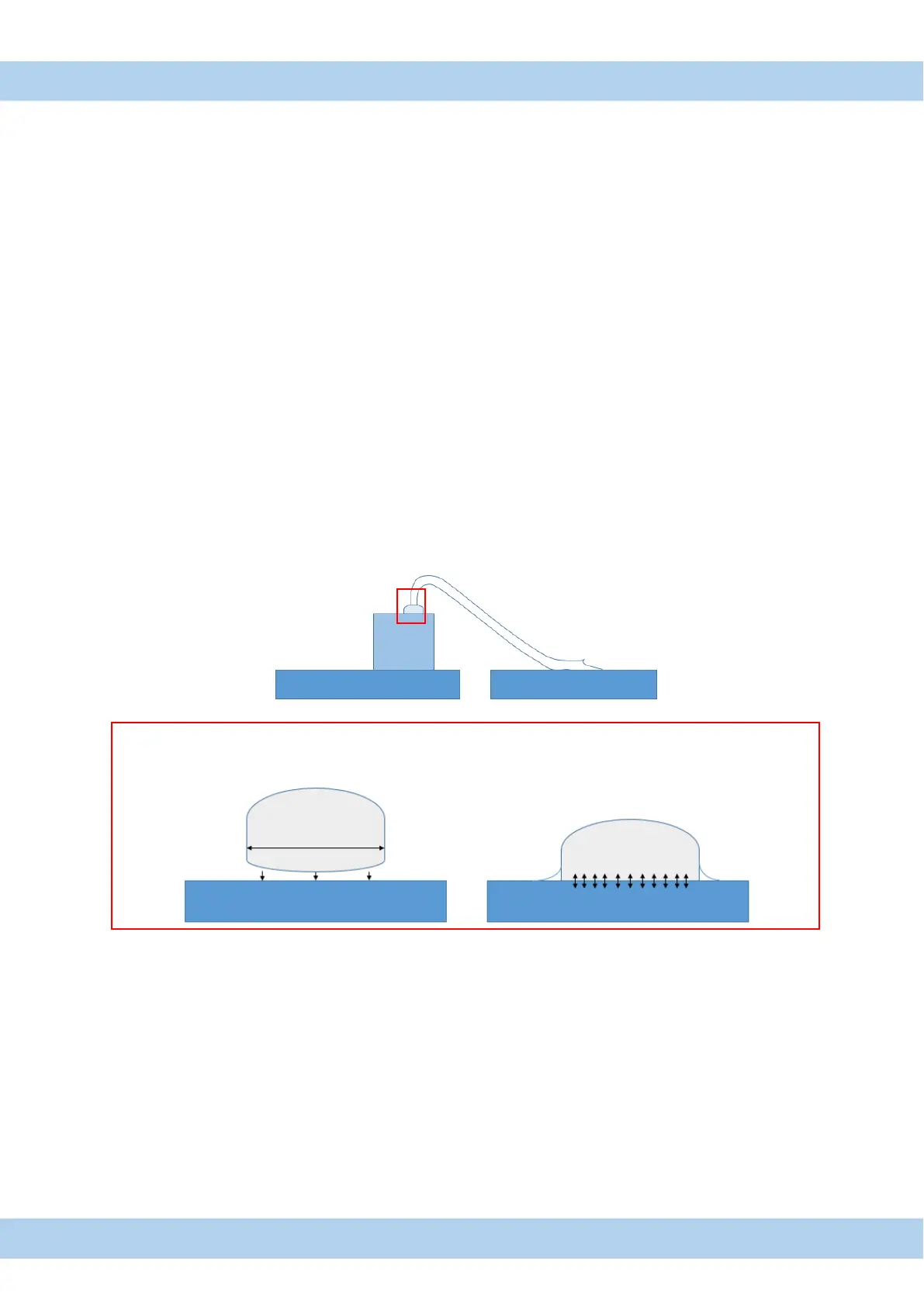

Ultrasonic Bonding is a type of friction based welding, but it is not a process which uses high temperatures to

fusion 2 metals. To connect the wire with the substrate, it is pressed onto the surface, while being moved laterally

according to the settings of the ultrasonic, as shown in the illustrations below. If heat is used as a fourth variable

the process is called Thermosonic Bonding

Ball in motion due to Ultrasonic,

is moving towards the substrate.

Friction based welding connects

the ball with the substrate.

Loading...

Loading...