TPT Wirebonder www.tpt.de Page 37 of 53 September 2016

32. Bump bonding

You can use standard Ball bonding tool for making Bumps.

The Ball size depends at Tail length, EFO power and wire size.

Recommended are: 400 Tail length, EFO power 90%

The ball size will never be smaller than three times wire size.

Example: for 25µ wire diameter it is minimal 75µ diameter Ball

The final Bump size depends to the bond parameters and bump tool.

In any case it will be bigger than the Ball size before bonding.

The Pitch (distance from Bump to Bump) depends to the bond tool.

There are special Bump tools for fine pitch and easy targeting.

Recommended tool: H61-17B 1732-10-16-437 for Bump bonding

There are two possibilities to make Bumps:

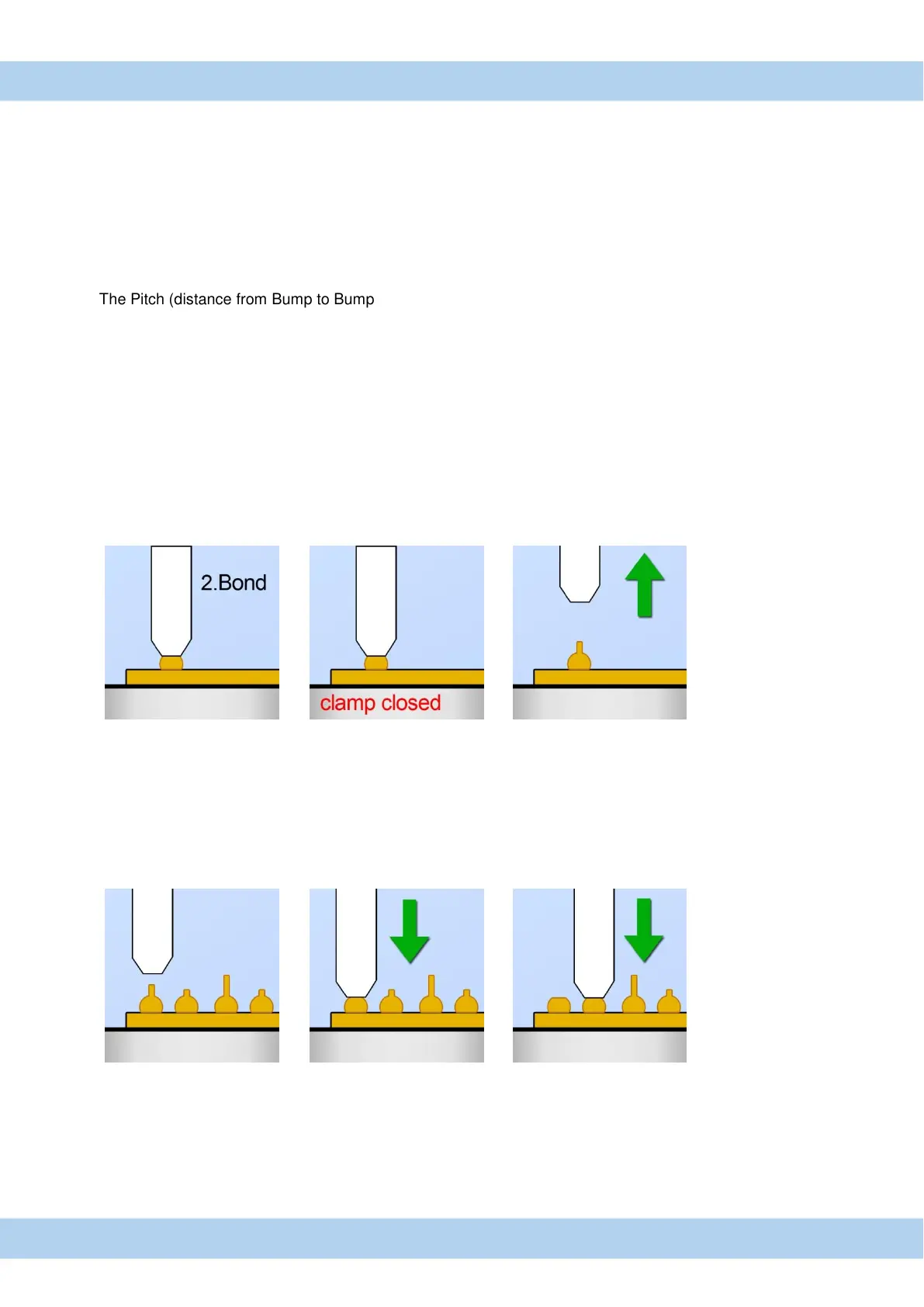

a) Bump with Tail and Coin Tool.

Change bondmode to “Ball Bump”.

Then you can do only the second Bond.

Now at second Bond are the parameters for the Bump bond.

After the Bump bond the wire will be cut and the next Ball will be made.

The wire will be break near above the Ball.

Some wires like HD6 from Hereaus are more constant about break point.

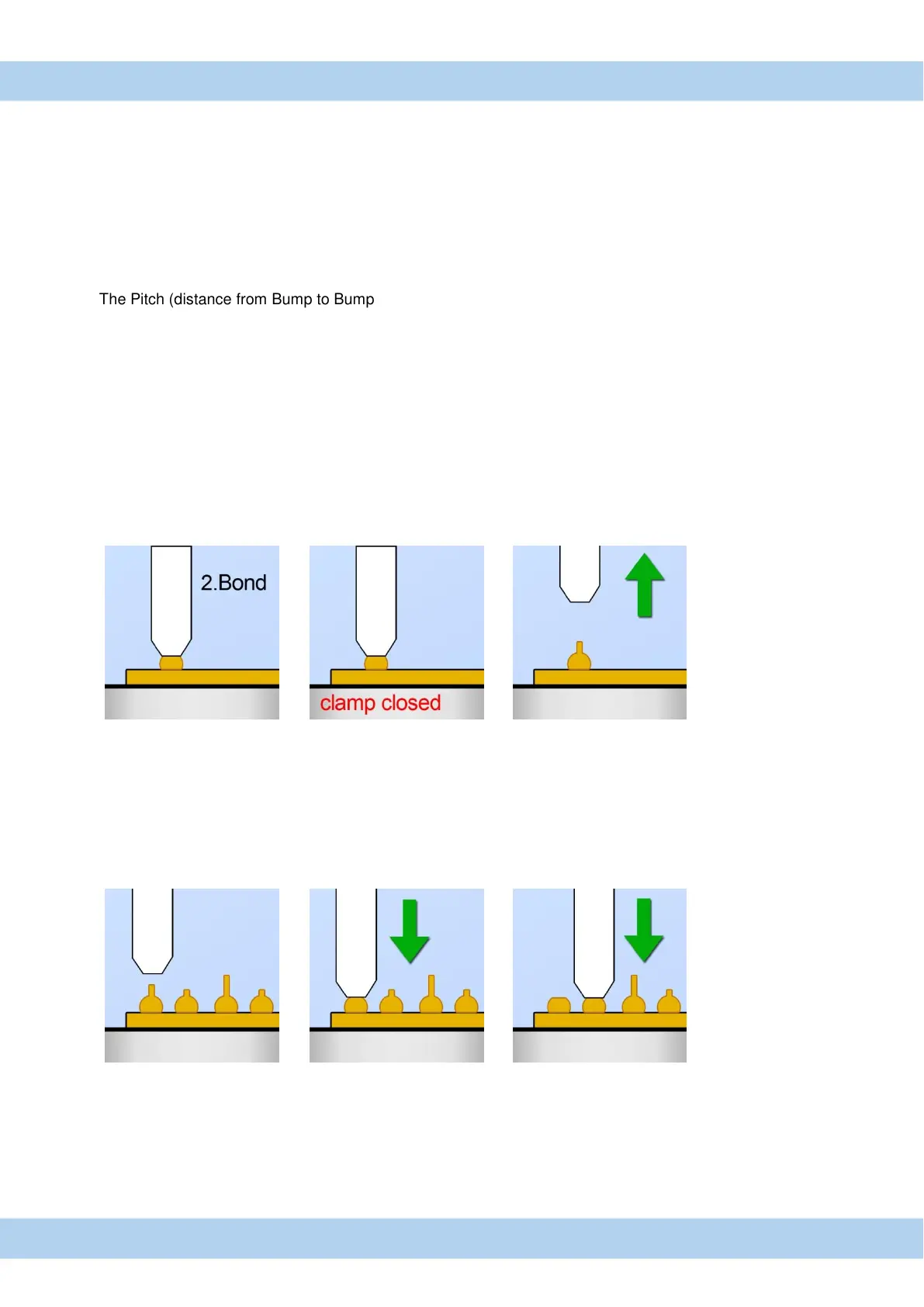

If you need flat Bumps you have to use a coin tool after making the Bumps.

Coin tool is complete flat, with no hole.

It depends at your application if you need a tail above the Bumps.

Loading...

Loading...