Parameterization and configuration

TR-Electronic GmbH 2004, All Rights Reserved Printed in the Federal Republic of Germany

Page 92 of 112 TR - ECE - BA - DGB - 0036 - 16 11/05/2018

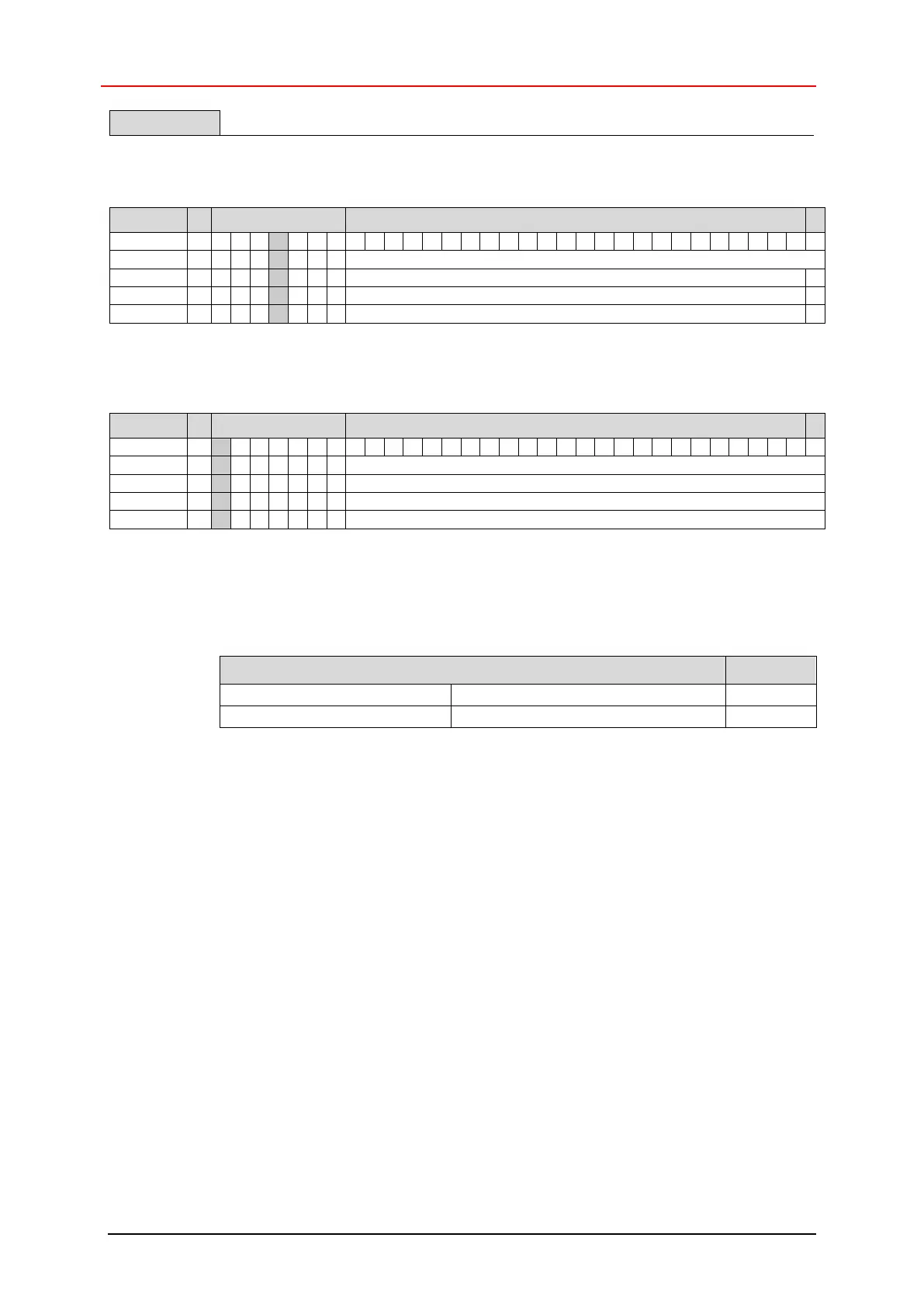

Setting of the counting direction

M = Master

Status-/Control bits Data bits

S = Slave

Bit 31 30 29

28

27 26 25 24 23 22 21 20 19 18 17 16 15 14 13 12 11 10 9 8 7 6 5 4 3 2 1 0

0 0 0

1

0 0 0

The selected counting direction is changed over from 0 to 1 or 1 to 0 using bit 28

0 0 0

0 / 1

0 / 1 0 1

The measuring system now acknowledges the newly selected counting direction in bit 0 and 28

0 / 1

0 0 0

0

0 0 0

Changeover is completed by setting bit 28 to 0

0 0 0

0 / 1

0 / 1 0 1

The process actual value is now output again

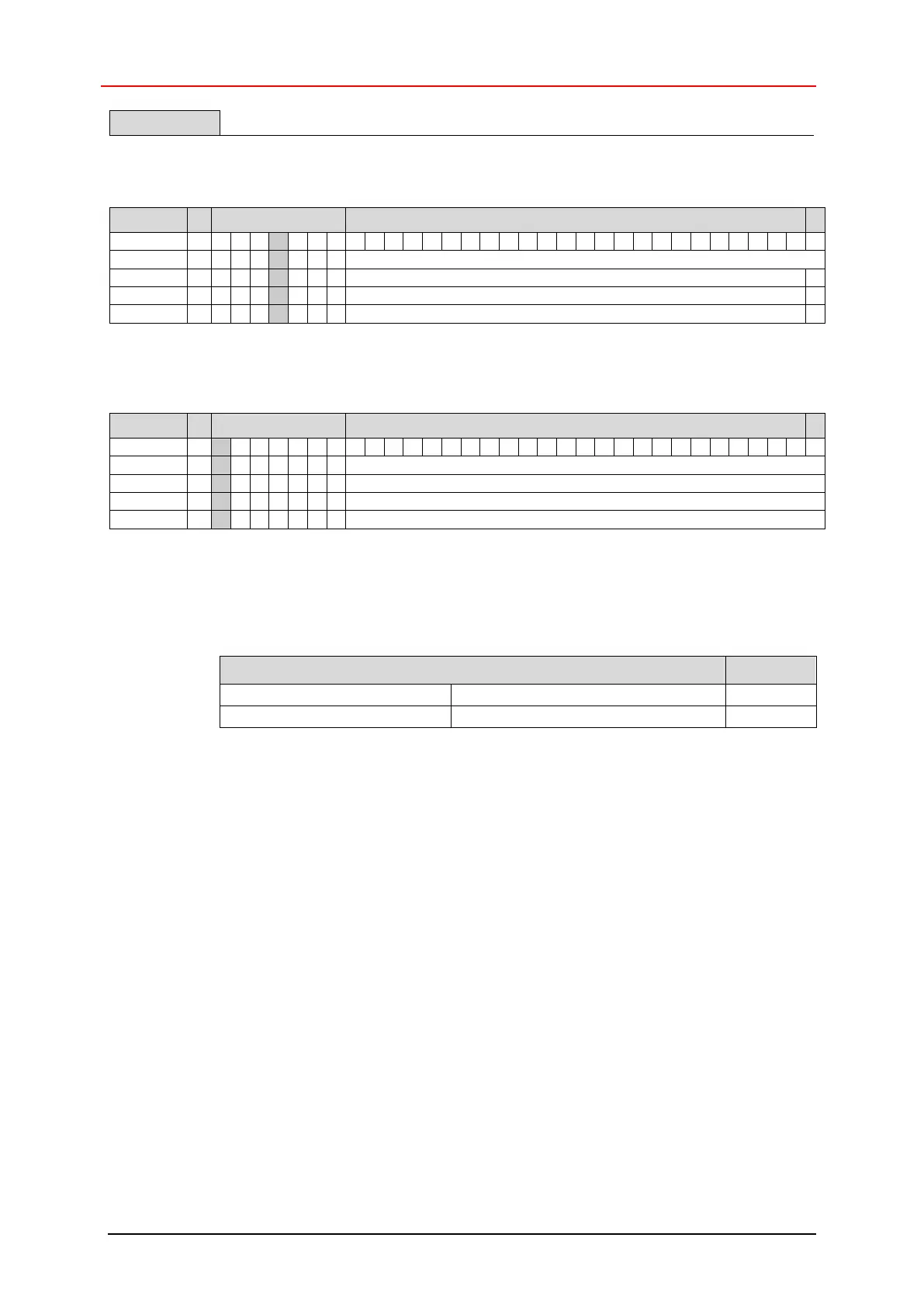

Preset adjustment

M = Master

Status-/Control bits

Data bits

Bit

31

30 29 28 27 26 25 24 23 22 21 20 19 18 17 16 15 14 13 12 11 10 9 8 7 6 5 4 3 2 1 0

1

0 0 0 0 0 0

Here the preset value is transferred as desired new actual value

S-->M

0

0 0 0 0 0 0

The

measuring system

acknowledges the takeover in bit 7 of the status byte

0

0 0 0 0 0 0

By setting the bit 31 to 0, the adjustment is finished

0

0 0 0 0 0 0

The process actual value is now output again

7.11.5 Short Diagnostics

Availability Page

TR-Mode Position+Velocity

TR-Mode High Resolution+Velocity

The number of diagnosis bytes can be restricted from 6+51 bytes to 6+10 bytes with

this parameter, such that the measuring system can also be operated with older

PROFIBUS master releases.

Loading...

Loading...