Installation: Mechanical

18 CVHH-SVX001A-EN

5. Once the isolators are in place, lower the chiller—

working from end to end—in small increments to

maintain stability.

6. When lift is complete, detach the clevis connections

and safety chain.

Special Lift Requirements

If the chiller cannot be moved using a standard chiller lift,

consider the following:

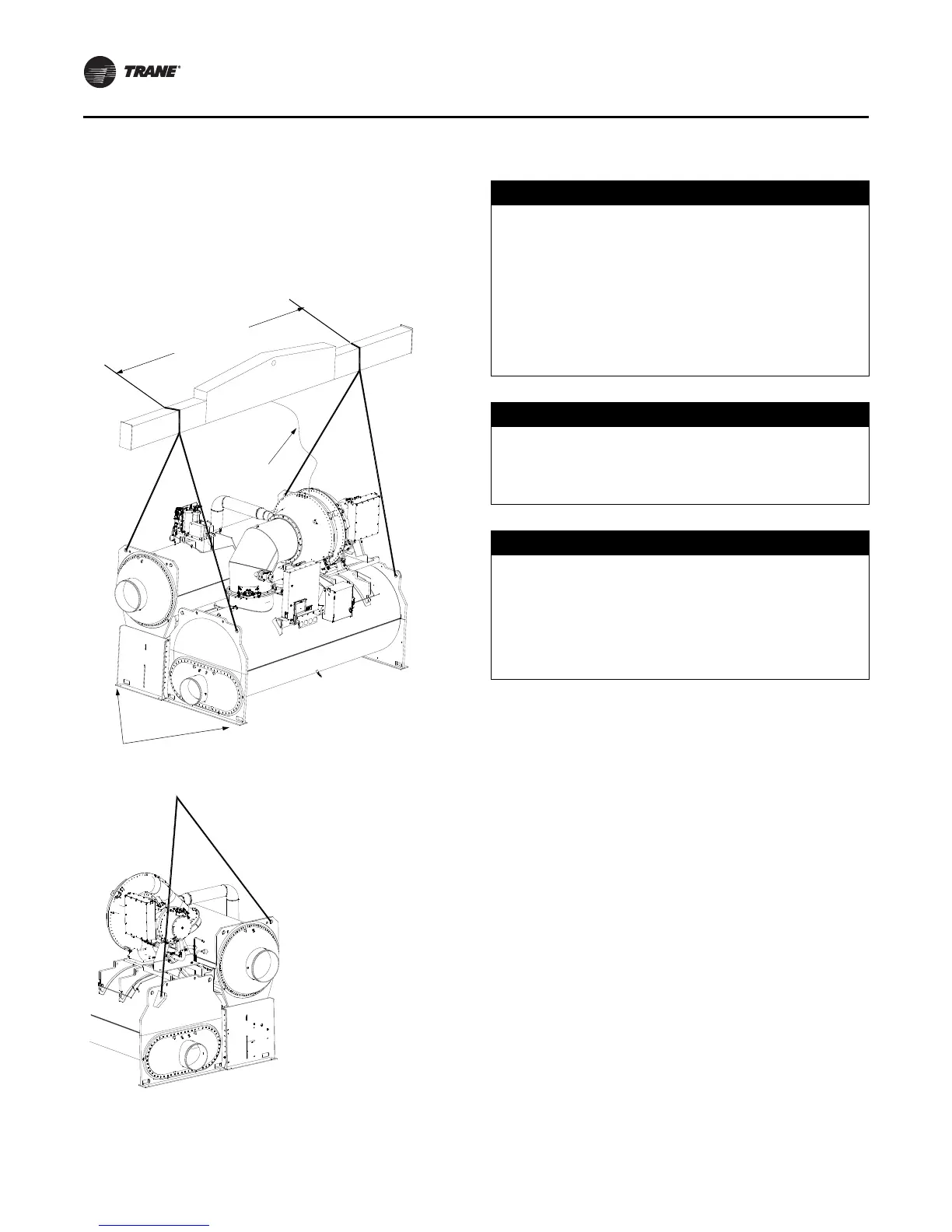

• When job site conditions require rigging of the chiller

at an angle greater than 45° from horizontal (end-to-

end), the unit may require removal of the compressor.

Contact Trane or an agent of Trane specifically

authorized to perform start-up and warranty of Trane

®

products regarding the disassembly and reassembly

work. For m ore information, refer to

“ Factory Warranty

Information,” p. 4

.

Note: Disassembly and reassembly work includes

dowel-pinning the compressor and removing it

from the unit. Contact Trane or an agent of

Trane specifically authorized to perform start-

up and warranty of Trane

®

products for specific

rigging instructions. Do NOT attempt to rotate

the chiller onto its side.

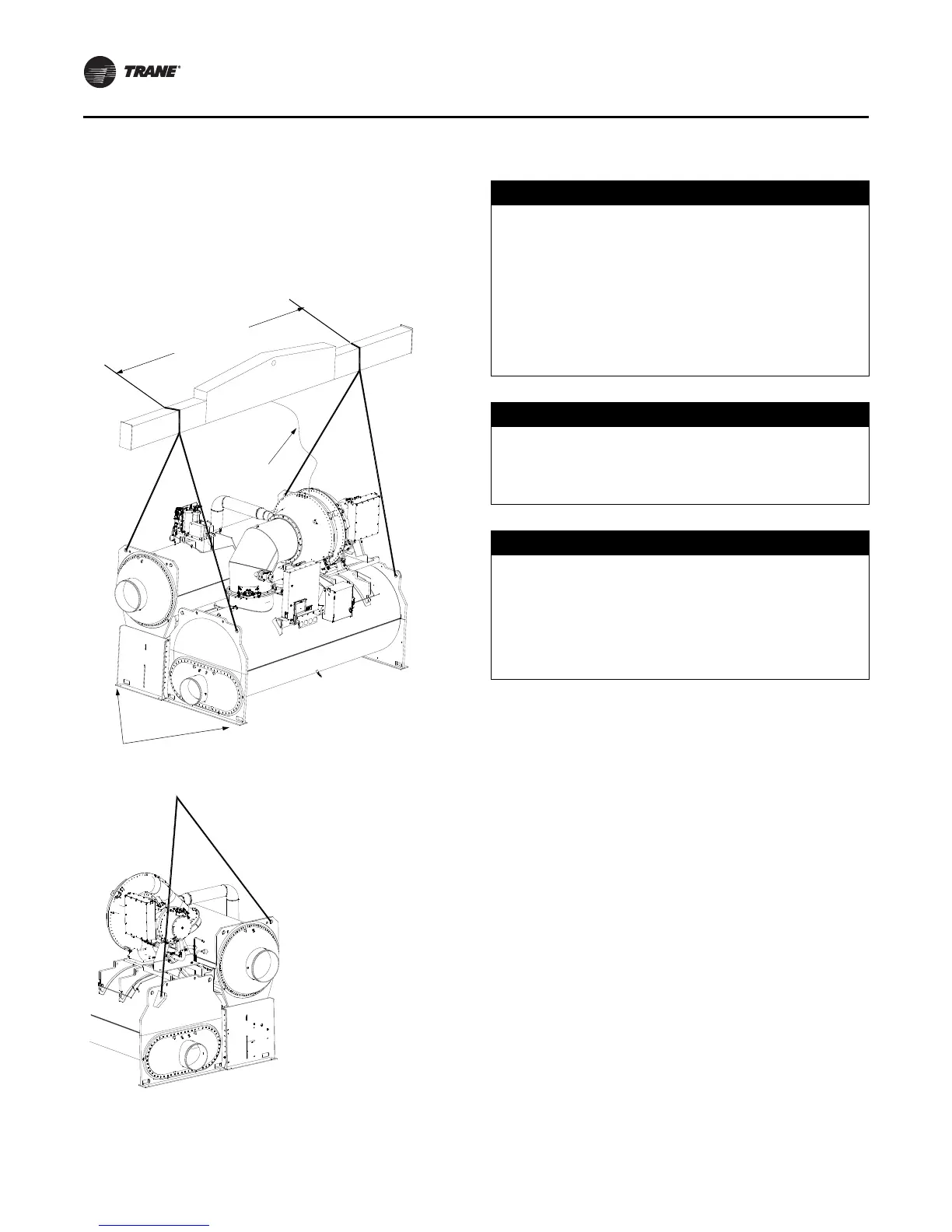

• When lifting the chiller is either impractical or

undesirable, attach cables or chains to the jacking slots

shown in

Figure 5, p. 18; then push or pull the unit

across a smooth surface. Should the chiller be on a

shipping skid, it is not necessary to remove the skid

from the chiller before moving it into place.

• If removal of the compressor or economizer assembly

is necessary to move the chiller to the operating

Figure 5. Typical rigging arrangements for Simplex

units

Safety

chain or

cable

Jack slots

4.572 m eters

(15 feet)

minimum

effective length

NOTICE:

Oil Loss!

Failure to prevent oil migration out of the oil tank could

result in equipment failure or property-only damage. To

prevent oil migration out of the oil tank during lifting

procedures, remove the oil from the oil tank if the unit

will be lifted at any angle greater than 15° from

horizontal end-to-end. If oil is allowed to run out of the

oil tank into other areas of the chiller, it will be

extremely difficult to return the oil to the oil tank even

during operation.

NOTICE:

Equipment Damage!

Moving the chiller using a fork lift could result in

equipment or property-only damage. Do not use a fork

lift to move the chiller!

NOTICE:

Compressor Alignment!

Failure to preserve compressor alignment could result

in equipment or property-only damage. Lifting the

compressor/motor assembly from the shells without

factory-installed doweling in the compressor casting

flanges could result in misalignment of the compressor

castings.

Loading...

Loading...