Start-up and Shut-down

78 CVHH-SVX001A-EN

If the STOP key is pressed on the operator interface, the

chiller will follow the same stop sequence as above except

the chilled water pump relay will also open and stop the

chilled water pump after the chilled water pump delay

timer has timed out after compressor shut down (see

Figure 45).

If the “ Immediate Stop” is initiated, a panic stop occurs

which follows the same stop sequence as pressing the

STOP key once except the inlet guide vanes are not

sequence closed and the compressor motor is

immediately turned off.

Power Up Diagram

Figure 42, p. 76 illustrates Tracer AdaptiView during a

power up of the main processor. This process takes from

30 to 50 seconds depending on the number of installed

Options. On all power ups, the software model always will

transition through the Stopped software state

independent of the last mode. If the last mode before

power down was Auto, the transition from Stopped to

Starting occurs, but it is not apparent to the user.

Ice Machine Control

The control panel provides a service level Enable or

Disable menu entry for the Ice Building feature when the

Ice Building option is installed. Ice Building can be entered

from Front Panel, or if hardware is specified the control

panel will accept either an isolated contact closure 1K9

Terminals J2-1 and J2-2 (Ground)) or a remote

communicated input (BAS) to initiate the ice building

mode where the unit runs fully loaded at all times. Ice

building will be terminated either by opening the contact

or based on entering evaporator fluid temperature. The

control panel will not permit the Ice Building mode to be

entered again until the unit is switched to the non-ice

building mode and back into the ice building m ode. It is not

acceptable to reset the chilled water setpoint low to

achieve a fully loaded compressor. When entering ice

building, the compressor will be loaded at its maximum

rate and when leaving ice building the compressor will be

unloaded at its maximum rate. While loading and

unloading the compressor, all surge detection will be

ignored. While in the ice building mode, current limit

setpoints less than the maximum will be ignored. Ice

Building can be terminated by one of the following means:

• Front panel disable.

• Opening the external Ice. Contacts/ Remote

communicated input (BAS).

• Satisfying an evaporator entering fluid temperature

setpoint (default is -2.8°C [27°F]).

• Surging for 7 minutes at full open IGV.

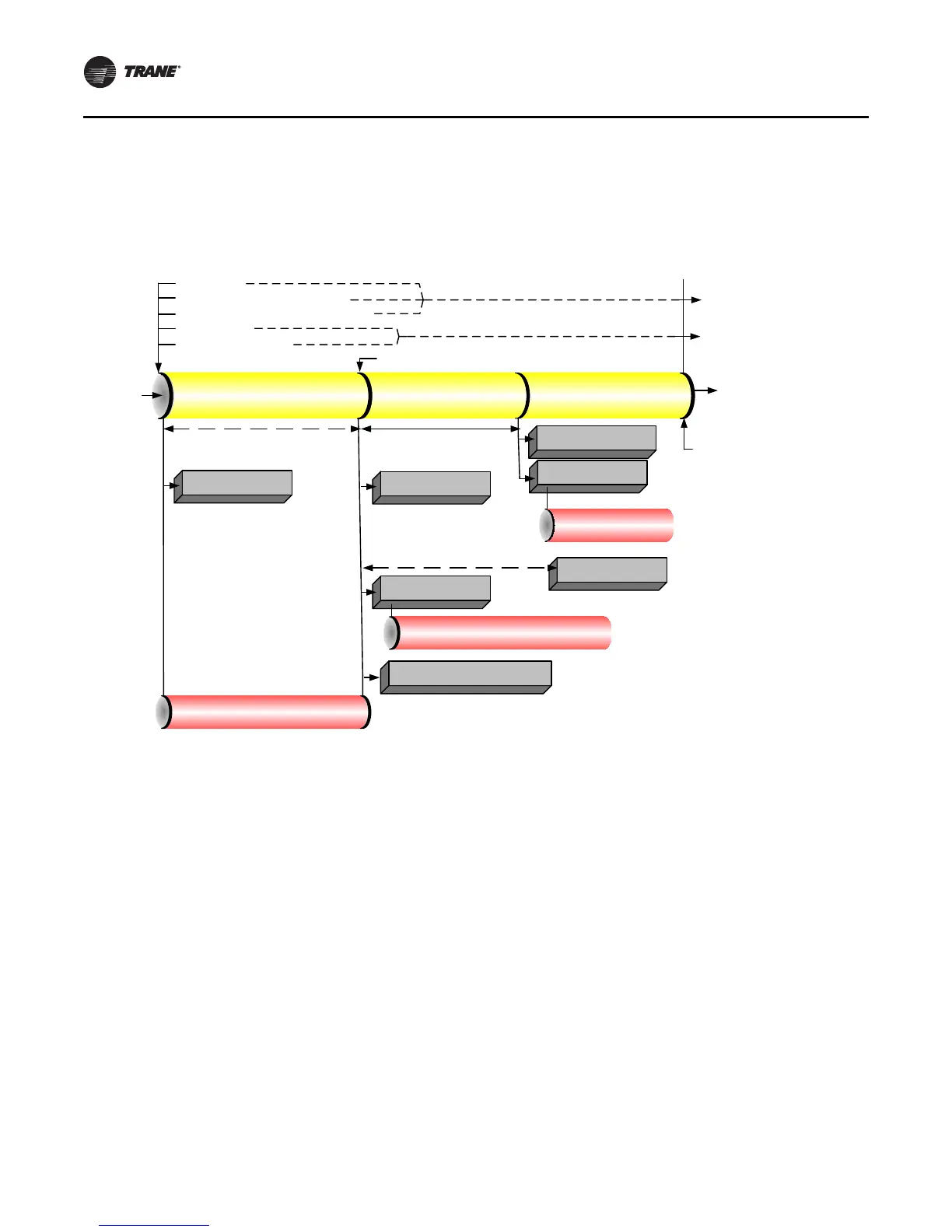

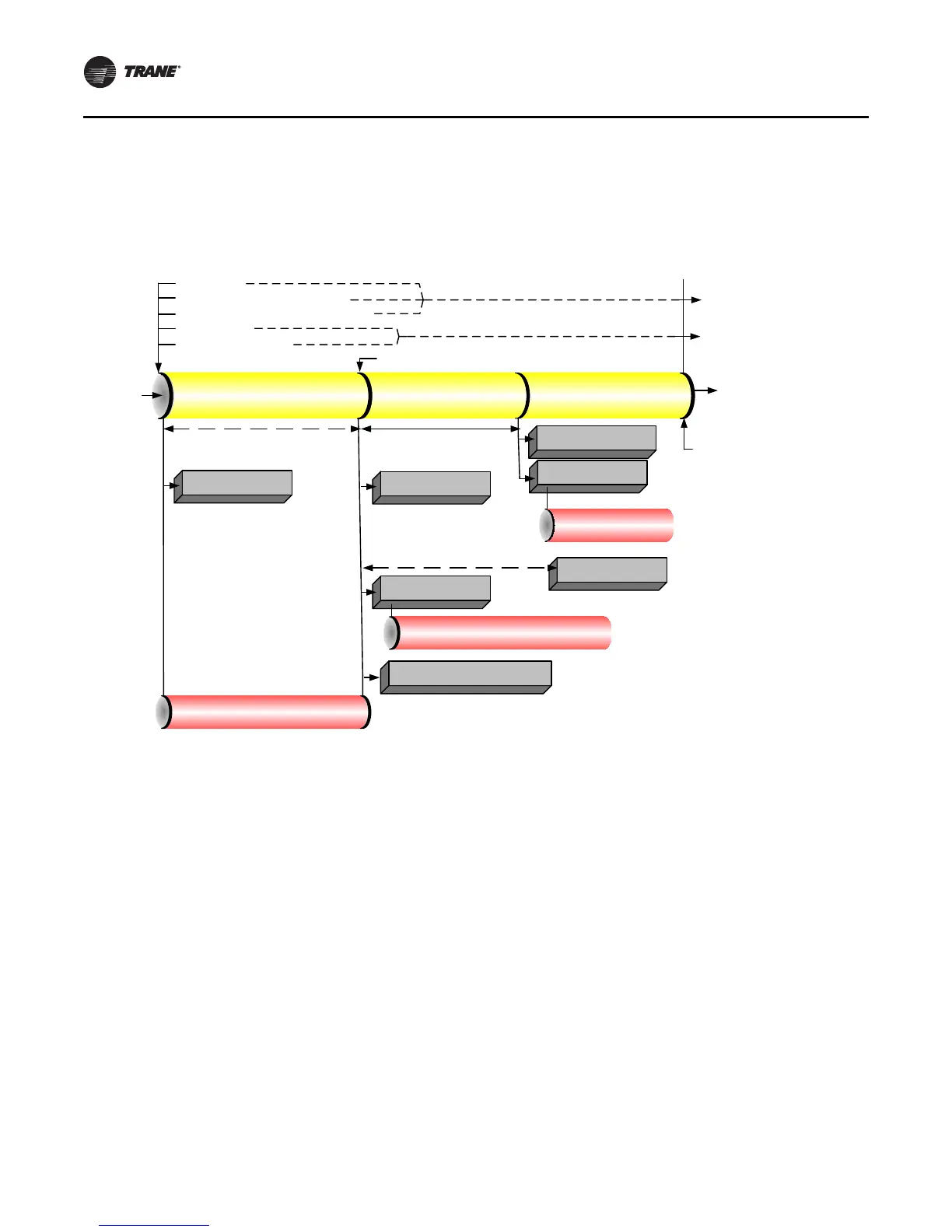

Figure 45. Sequence of operation: normal shut-down to stopped and run inhibit

Local Stop

Normal Latching Diagnostic

Normal Non-Latching Diagnostic

Tracer Stop

External Auto-Stop

IGV Closed

Preparing Shutdown Shutting Down

Shutting Down

Running

Stopped

Run Inhibit

Stopped

or

Run Inhibit

Evap Pump

Off Delay

and Postlube

Complete

Close IGV (0–50 sec)

Postlube 3 min

Evap Pump Off Delay Time

(0–30 min)

Command IGV Closed

Enforce All Running Mode Diagnostics

De-Energize Condenser

Water Pump Relay

De-Energize

Compressor

Confirm No Compressor Currents

Within 8 sec

Hold position of Oil Vent Line Valve

Open Oil Vent Line Valve

De-Energize Oil Pump

Confirm No Oil Pressure*

5 min after oil pump

is de-energized

De-Energize Evaporator

Water Pump Relay

*Note: No oil pressure is less than 20.7 kPad (3 psid)

Loading...

Loading...