Vent Piping

34 CVHH-SVX001A-EN

Trane RuptureGuard

General Information

The Trane RuptureGuard™ refrigerant containment

system replaces the rupture disk on new low pressure

chillers utilizing R-1233

zd

(E). The RuptureGuard system

consists of a solid-metal, (non-fragmenting) reverse-

buckling rupture disk, and automatically re-seating relief

valve. The relief valve and the rupture disk are rated at the

chiller’s maximum working pressure level. If the chiller’s

refrigerant pressure exceeds the rupture disk burst rating,

the disk bursts, releasing pressure to the relief valve. The

relief valve vents the pressure down to a safe level and

then re-seats, thus minimizing the amount of refrigerant

vented to the atmosphere.

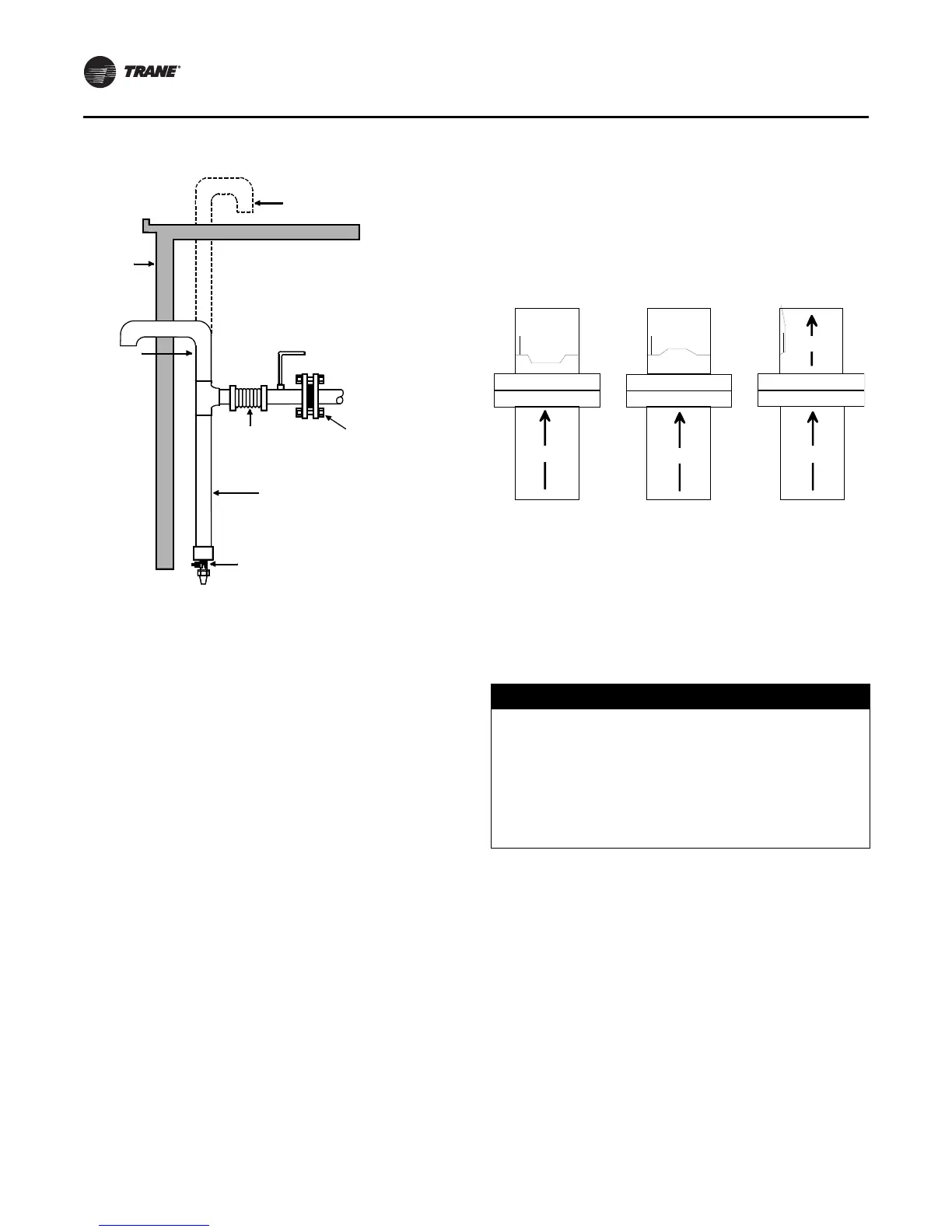

Figure 21 illustrates the

operation of a reverse buckling rupture disk.

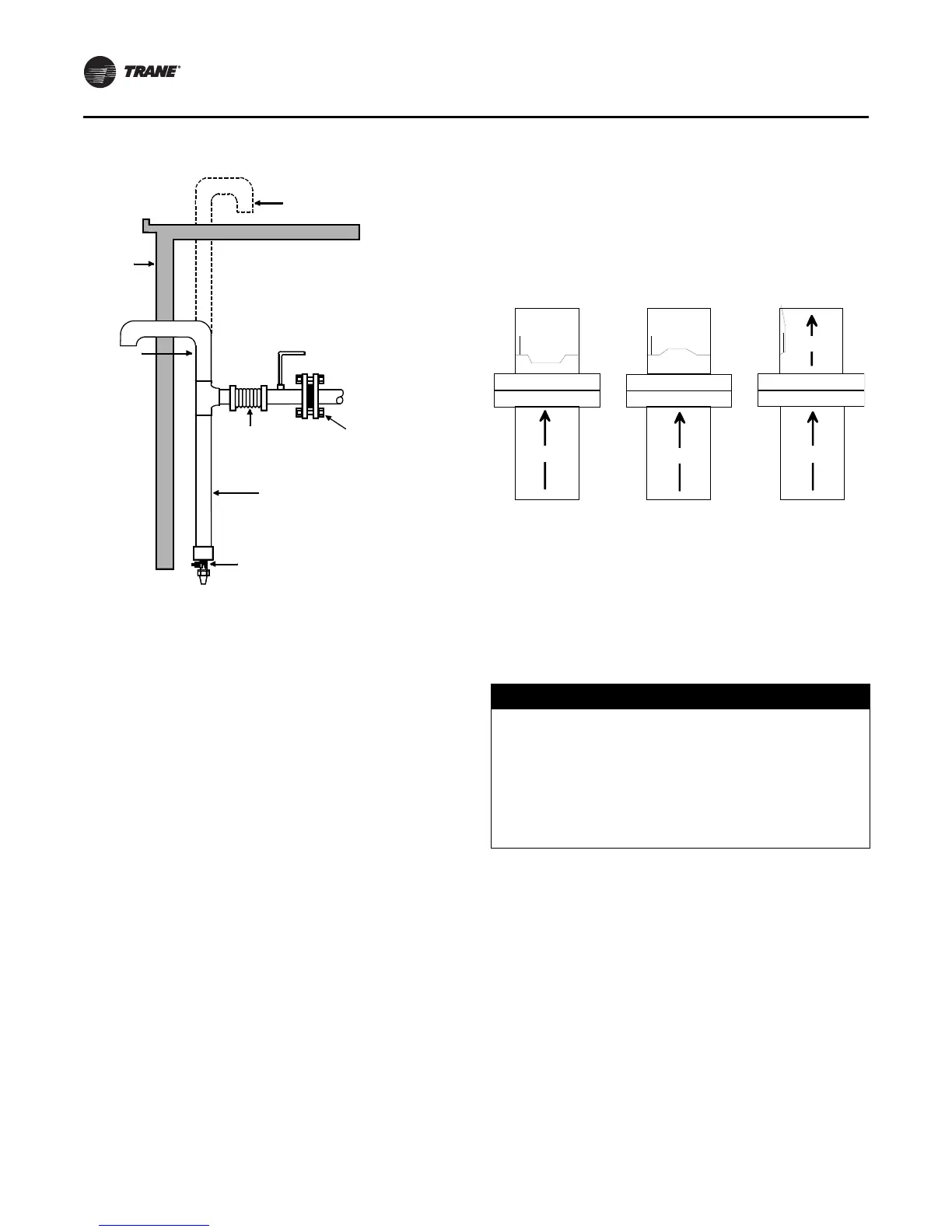

To prevent water, refrigerant and/or other debris such as

rust from hindering the operation of the valve, a drip leg

should be installed immediately after or downstream of

the RuptureGuard (see

Figure 22).

Connection to External Vent Line and Drip

Leg

With RuptureGuard installed horizontally, the drain plug

downstream of the valve relief plug and nearest to the

bottom of the valve body should be piped to the drip leg

in the vent line. This will allow the removal of any

condensate formed within the valve body.

Provisions, such as installing a set of flanges (see

Figure 22) or other disconnect m eans, must be made in the

discharge vent piping. This will allow the piping

downstream of the valve to be easily removed for an

annual inspection, to replace the rupture disk, or for any

other servicing need.

Figure 20. Arrangement for rupture disk relief piping

Alternate

Purge discharge

vent line

Outside

wall

Support

this pipe

Flexible

steel

connection

Drip leg

(length as required

for easy access)

1/ 4 in. FL x 1/ 4 in. NPT

drain valve

Rupture disk

assembly

Figure 21. Reverse buckling rupture disk

NOTICE:

Equipment Damage!

Trane assumes no responsibility for equipment damage

caused by insufficient drainage of drip leg. All vent lines

must be equipped with a drip leg of sufficient volume

to hold the expected accumulation of water and/or

refrigerant. The drip leg must be drained periodically to

assure that it does not overflow and allow fluid to flow

into the horizontal portion of the vent line.

Chiller

ChillerChiller

Flow

Flow

Flow

Flow

Flow

Disk in normal

operating position.

Chiller pressure is

below 50 psig.

The disk snaps

open through the

score line of the

outlet ring and the

pr essure is vent ed.

The outlet ring is

designed with a

h in g e ar ea t o r etai n

the disk petal.

When chiller

pressure exceeds

the disk’s rated

burst pressure, t he

disk begins to tear

open along the

score line of the

outlet ring.

Flow

Flow

Flow

Flow

Flow

Chiller

Chiller Chiller

Loading...

Loading...