Start-up and Shut-down

76 CVHH-SVX001A-EN

There are five generic states that the software can be in:

•Power Up

•Stopped

•Starting

• Running

•Stopping

Descriptions

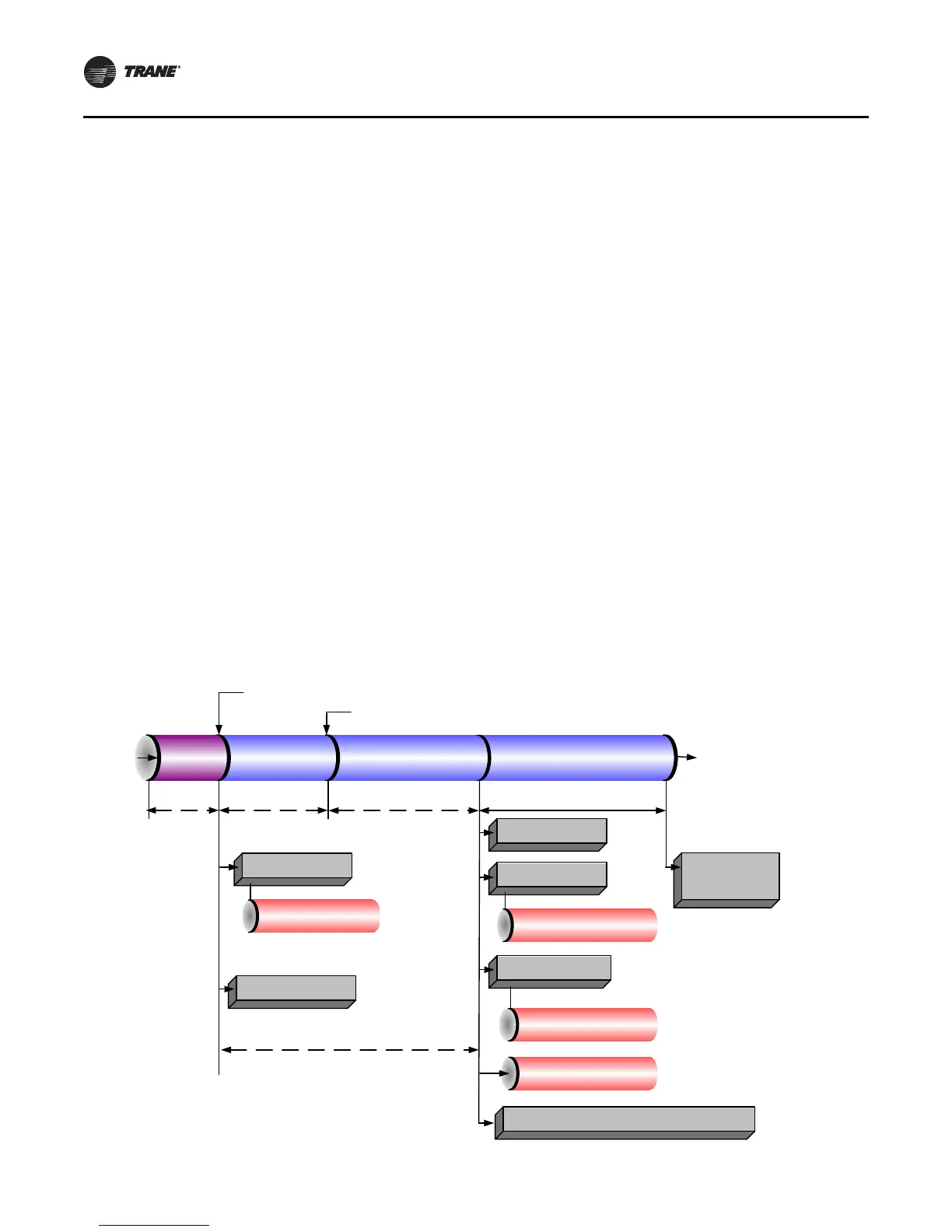

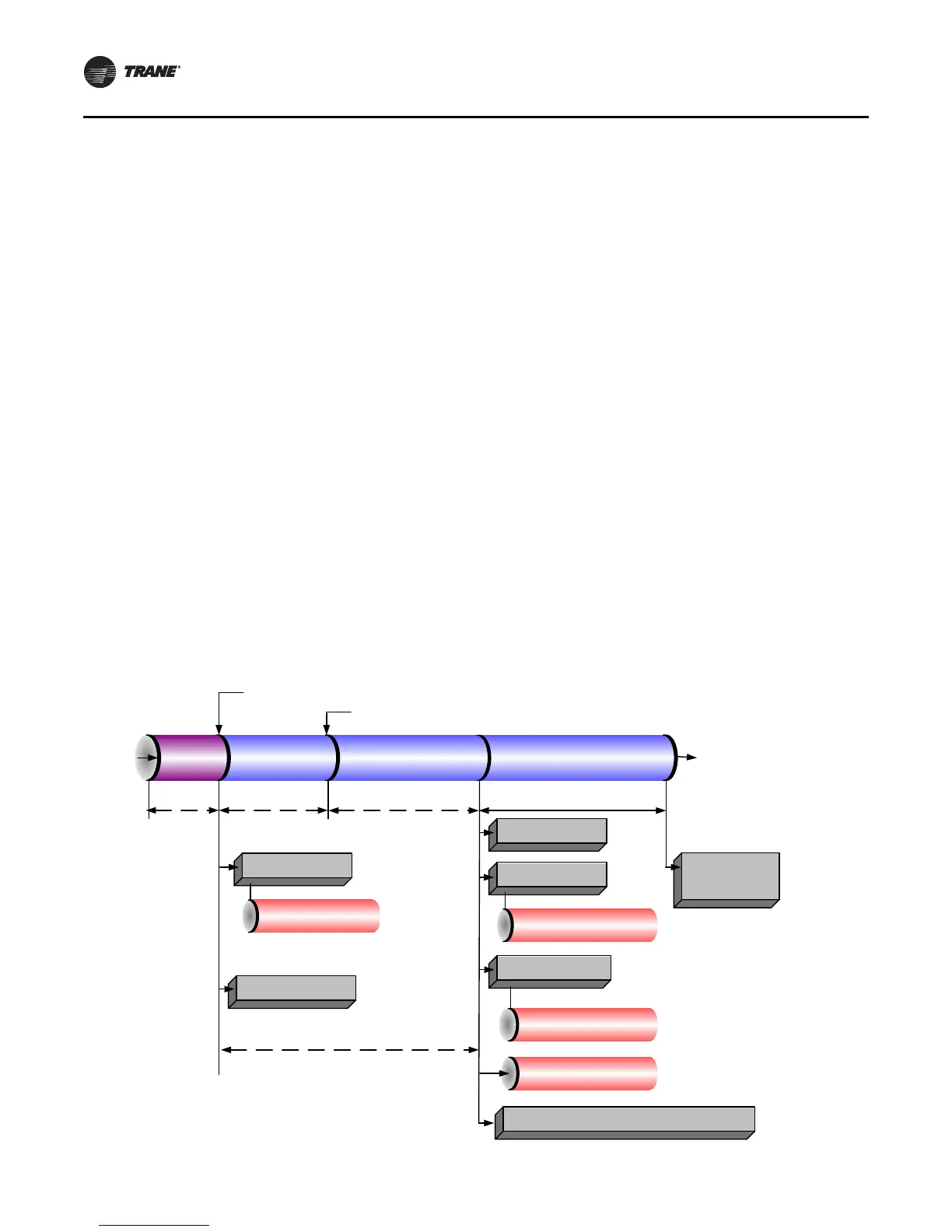

• The time line indicates the upper level operating mode,

as it would be viewed on Tracer AdaptiView.

• The shading color of the cylinder indicates the

software state.

• Text in parentheses indicates sub-mode text as viewed

on Tracer AdaptiView.

• Text above the time line cylinder is used to illustrate

inputs to the Main Processor. This may include User

input to the Tracer AdaptiView Touch screen, Control

inputs from sensors, or Control Inputs from a Generic

BAS.

• Boxes indicate Control actions such as Turning on

Relays, or moving the Inlet Guide Vanes.

• Smaller cylinders indicate diagnostic checks, text

indicates time based functions, solid double arrows

indicate fixed timers, and dashed double arrows

indicate variable timers.

Start-up Sequence of Operation—

Wye-Delta

Logic Circuits within the various modules will determine

the starting, running, and stopping operation of the chiller.

When operation of the chiller is required the chiller mode

is set at “Auto.” Using customer supplied pow er, the chilled

water pump relay is energized and chilled water flow must

be verified within 4 minutes and 15 seconds, at the same

time the oil vent line valve is opened. The main processors

logic decides to start the chiller based on the differential to

start setpoint. With the differential to start criteria met, the

module then energizes condenser water pump relay with

customer supplied power (see

Figure 42, p. 76).

Based on the Restart Inhibit function and the Differential to

Start setpoint, the oil and refrigerant pump is energized,

and the oil vent line valve is closed to the minimum

position. The oil pressure must be at least 82.7 kPad

(12 psid) for 60 continuous seconds and condenser water

flow verified within 4 minutes and 15 seconds for the

compressor start sequence to be initiated. After the

compressor starts, the oil vent line valve begins to open;

it can take between 15 and 30 minutes to fully open

depending on the chiller running conditions.

The compressor motor starts in the “ Wye” configuration

and then, after the compressor motor has accelerated and

the maximum phase current has dropped below

85 percent of the chiller nameplate RLA for 1.5 seconds,

the starter transitions to the “ Delta” configuration.

Figure 42. Sequence of operation: power up to starting

Power

Applied

to

Controls

Last Chiller Mode

Was Auto

Call for Cooling

Auto Waiting to Start

Waiting to Start

Starting

Compressor

UC800 Boot

Time

(30–50 sec)

Enforce Power

Up Start Delay

Timer (0–30 min)

Wait for Highest Motor Winding

Temp to Fall Below 73.9°C (165°F)

Wait for Oil Temp to Rise Above

Sat Evap + -1.1°C (30°F)

and 37.8°C (100°F)

Prelube (60 sec)

Begin Oil Vent Line

Valve low limit

venting

Overdrive IGV Closed

Energize Condenser

Water Pump Relay

Confirm Condenser Water Flow

Within 4 min 15 sec

(6 sec Filter)

Energize Oil Pump Relay

Confirm 82.7 kPad (12 psid)

Oil Pressure

Within 3 min

Check for High Vacuum

Lockout

Initialize Oil Vent Line Valve to Minimum Open Position

Energize Evaporator

Water Pump Relay

Confirm Evaporator Water

Flow Within 4 min 15 sec

(6 sec Filter)

Open Oil Vent Line Valve

Enforce Stop to Start Timer Using Values From

Real Time Clock (5–200 sec, 30 is Default)

Loading...

Loading...