Installation: Mechanical

CVHH-SVX001A-EN 19

location, contact Trane. For more information, refer to

“ Factory Warranty Information,” p. 4.

Unit Isolation

To m inimize sound and vibration transm ission through the

building structure, and to ensure proper weight

distribution over the mounting surface, always install

isolation pads or spring isolators under the chiller feet.

Note: Isolation pads (see

Figure 6) are provided w ith each

chiller unless spring isolators are specified on the

sales order.

Specific isolator loading data is provided in the unit

submittal package. If necessary, contact your local Trane

sales office for further information.

Important: When determining placement of isolation

pads or spring isolators, remember that the

control panel side of the unit is always

designated as the unit front.

Isolation Pads

When the unit is ready for final placement, position

isolation pads (457.2-mm sides) end for end under the full

length of the chiller leg. The pads measure 228.6 mm x

457.2 mm (9 in. × 18 in.) and on some units there may be

small gaps between pads. Pads are provided to cover

entire foot.

Remember that the chiller must be level within 1.6 mm

(1/16 in.) over its length and width after it is lowered onto

the isolation pads. In addition, all piping connected to the

chiller must be properly isolated and supported so that it

does not place any stress on the unit.

Spring Isolators

Spring isolators should be considered whenever chiller

installation is planned for an upper story location. Base

isolator placement is shown in

Figure 7; also refer to

Tab l e 3.

Spring isolators typically ship assembled and ready for

installation. To install and adjust the isolators properly,

follow the instructions given.

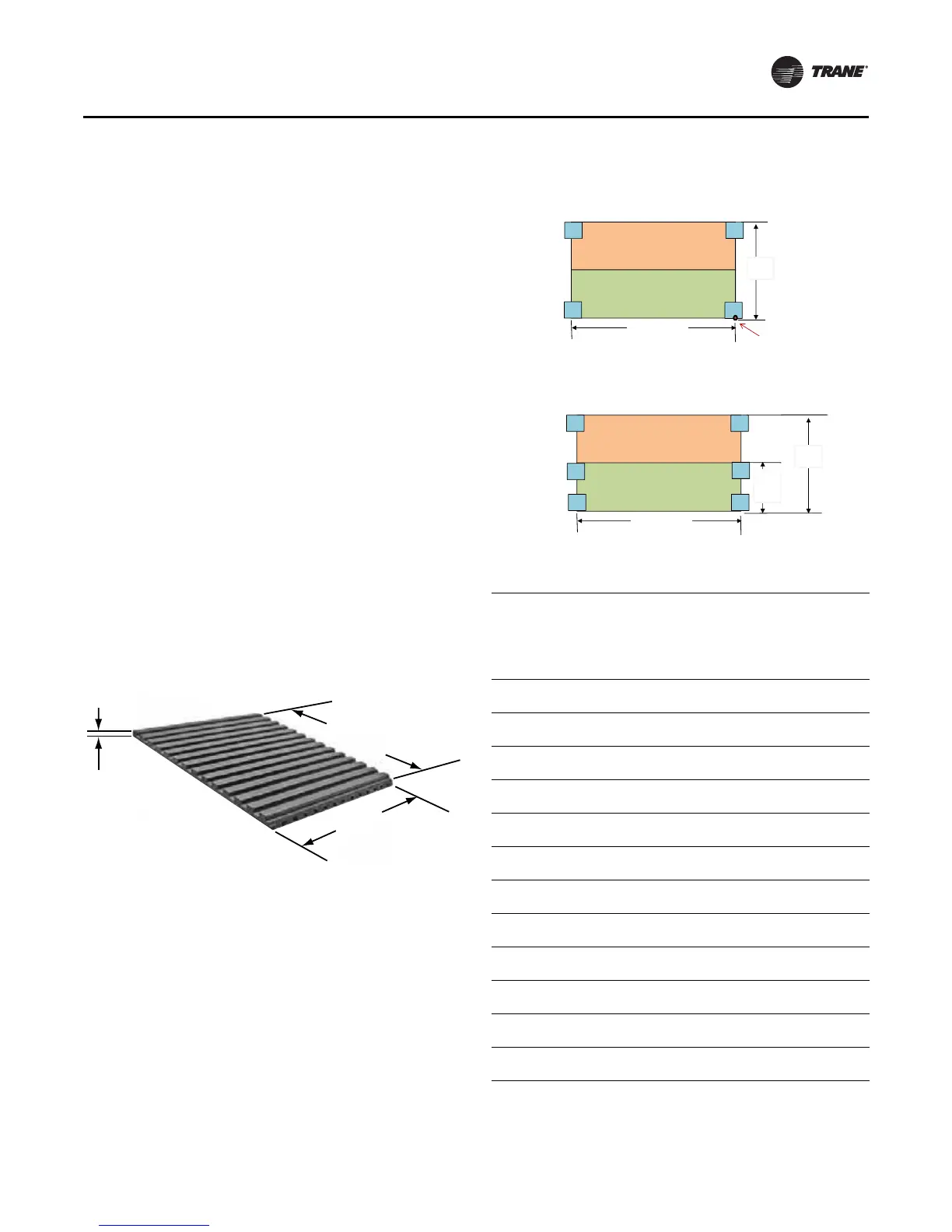

Figure 6. Isolation pad and dimensions

228.6 mm

(9 in.)

457.2 mm

(18 in.)

9.525 mm

(3/ 8 in.)

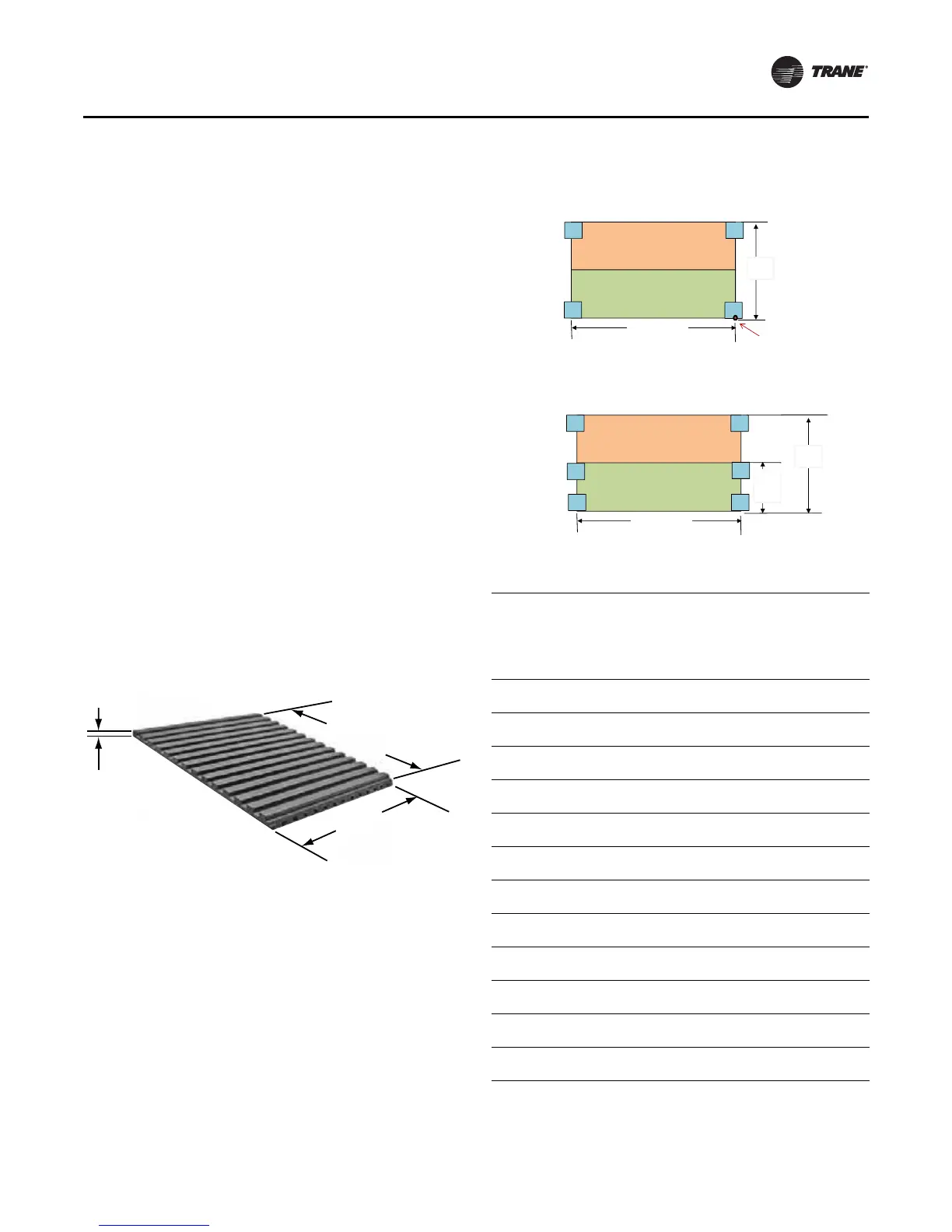

Figure 7. Isolation spring placement by shell size,

evaporator and condenser length

Table 3. Isolation spring placement, cm (in.)

EVSZ CDSZ W idth

Evap

W idth Length

I solator

Config

Origin

to

Center

o f R ear

P ad

Origin

to

Center

of

Middle

Pad

200L 200L

285.0

(112.2)

170.2

(67)

457.2

(180)

2

268.5

(105.7)

153.7

(60.5)

220L 220L

303.3

(119.4)

188.0

(74)

457.2

(180)

2

286.8

(112.9)

171.5

(67.5)

200L 20HL

336.0

(132.3)

170.2

(67)

457.2

(180)

2

319.5

(125.8)

153.7

(60.5)

220L 22HL

361.0

(142.5)

188.0

(74)

457.2

(180)

2

345.4

(136)

171.5

(67.5)

160M 20HM

323.3

(127.3)

154.9

(61)

406.4

(160)

2

306.8

(120.8)

138.4

(54.5)

200L 220L

285.2

(112.3)

170.2

(67)

457.2

(180)

2

268.7

(105.8)

153.7

(60.5)

160M 200M

270.3

(106.4)

154.9

(61)

406.4

(160)

2

253.7

(99.9)

138.4

(54.5)

100M 100M

264.4

(104.1)

N/ A

406.4

(160)

1

247.9

(97.6)

N/ A

100L 100L

264.4

(104.1)

N/ A

457.2

(180)

1

247.9

(97.6)

N/ A

130M 130M

277.6

(109.3)

N/ A

406.4

(160)

1

261.1

(102.8)

N/ A

100M 10HM

300.2

(118.2)

N/ A

406.4

(160)

1

283.7

(111.7)

N/ A

130M 13HM

313.4

(123.4)

N/ A

406.4

(160)

1

296.9

(116.9)

N/ A

Condenser

Evaporator

Length

2

5

1

4

6

3

Width

I solator Configuration 1

Origin:

Right front corner of

evap right front foot

Condenser

Evaporator

Length

2

5

1

4

6

3

Evap

Width

Width

I solator Configuration 2

Loading...

Loading...