System Control Circuit Wiring (Field Wiring)

64 CVHH-SVX001A-EN

Water Pump Interlock Circuits and Flow

Switch Input

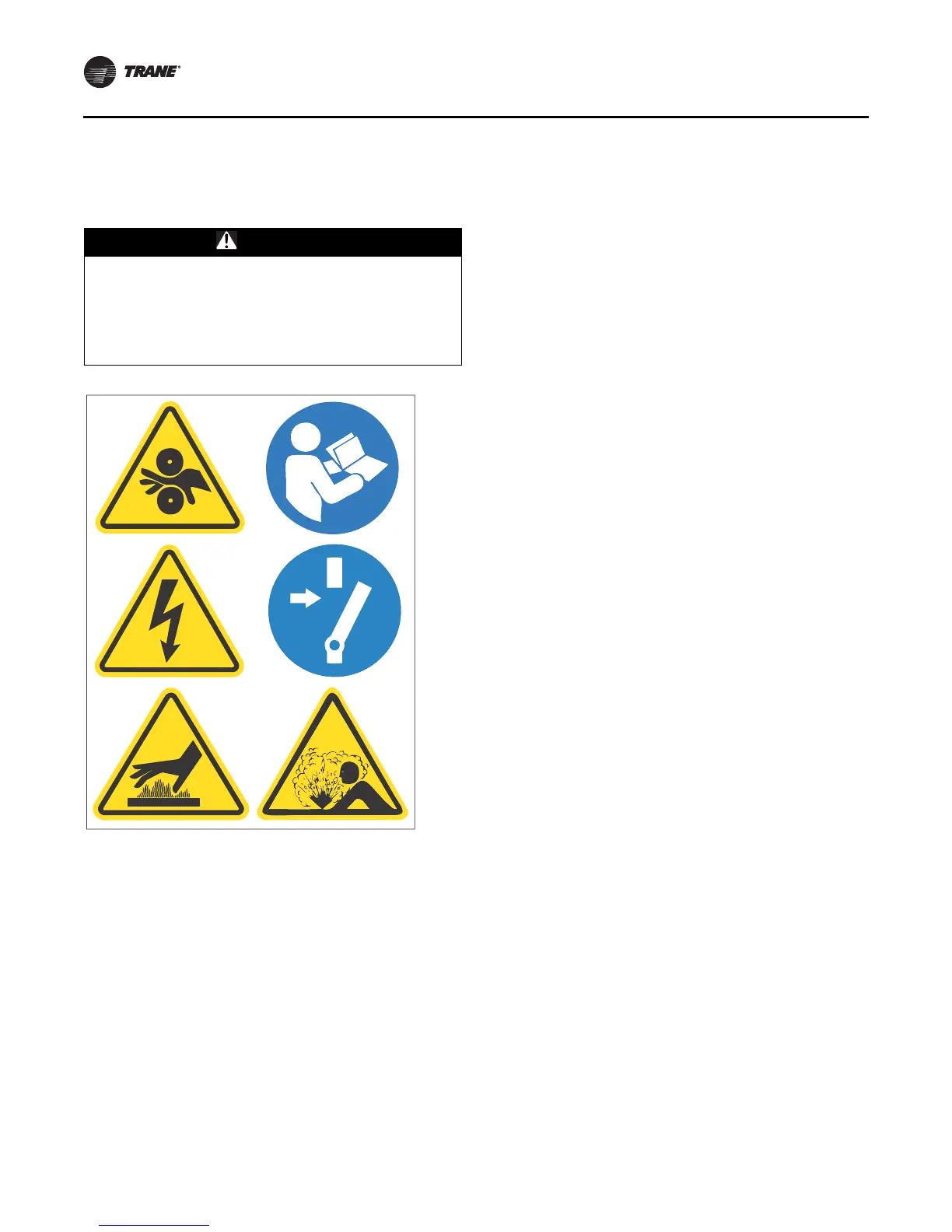

Note: Graphic labels (shown above) are used for CE

application only.

Important:

• Before servicing, disconnect all power sources and

allow at least 30 minutes for capacitors to discharge.

• All electrical enclosures—unit or remote—are IP2X.

Note: The circuits for the chilled water proof of flow and

the condenser water proof of flow do NOT require

external power. Refer to the wiring diagrams that

shipped with the chiller.

Chilled water pump

1. Wire the evaporator water pump contactor (5K42) to a

separate 120 volt single phase power supply with

14 AWG, 600 volt copper wire. For AWG/MCM

equivalents in mm

2

, refer to

Table 12, p. 47.

2. Connect circuit to 1K15-J2-6.

3. Use 1K15-J2-4 120 Vac output to allow the control

panel to control the evaporator water pump, or wire

the 5K1 contactor to operate remotely and

independently of the control panel.

Chilled water proof of flow

When this circuit is installed properly and the evaporator

pump is running and providing the required minimum

flow, this circuit will prove the evaporator water flow for

the chiller controls. Proof of evaporator water flow is

required before the start sequence will be allowed to

proceed and a loss of evaporator water flow during chiller

operation will result in a chiller shut-down.

Refer to as-built schematics on the inside of the control

panel for field wiring. This is a dry binary input; normally-

open, closure for flow. Apply no external power.

1. With factory-installed ifm efector flow-sensing

devices, a field-provided secondary flow-sensing

device is recommended with applications having 3.3°C

(38°F) and below leaving evaporator water

temperatures. When a secondary flow-sensing device

is used, remove the factory jumper and install its

contacts between 1X1-5 to 1K26-4; this places the

secondary flow sensing device in series with the

ifm efector.

2. For field-provided primary proof of flow devices,

connect the primary proof of flow device between

terminals 1X1-5 to 1K16-J3-2. A secondary field device

is recommended with applications having 3.3°C (38°F)

and below leaving evaporator water temperatures,

and must be field-wired in series with the primary

proof of flow device.

Condenser water pump

1. Wire the condenser water pump contactor (5K43) to a

separate 120-volt, single phase power supply with

14 AWG, 600-volt copper wire. For AWG/MCM

equivalents in mm

2

, refer to

Table 12, p. 47.

2. Connect circuit to control panel terminals 1K15-J2-3.

3. Use 1K15-J2-1 120 Vac output to allow the control

panel to control the condenser pump.

Condenser water proof of flow

When this circuit is installed properly and the condenser

pump is running and providing the required minimum

condenser water flow, this circuit will prove the condenser

water flow for the chiller controls. Proof of condenser

water flow is also required for the start sequence will be

allowed to proceed and a loss of condenser water flow

during chiller operation will result in a chiller shut-down.

Refer to as-built schematics on the inside of the control

panel for field wiring. This is a dry binary input; normally-

open, closure for flow. Apply no external power.

(c) Standard low-voltage circuits (less than 30 Vac) m ust be separated from 120 Vac or higher wiring.

WARNING

Hazardous Voltage!

Failure to disconnect power before servicing could

result in death or serious injury. Disconnect all electric

power, including remote disconnects before servicing.

Follow proper lockout/ tagout procedures to ensure the

power can not be inadvertently energized.

Loading...

Loading...