Operating Principles

70 CVHH-SVX001A-EN

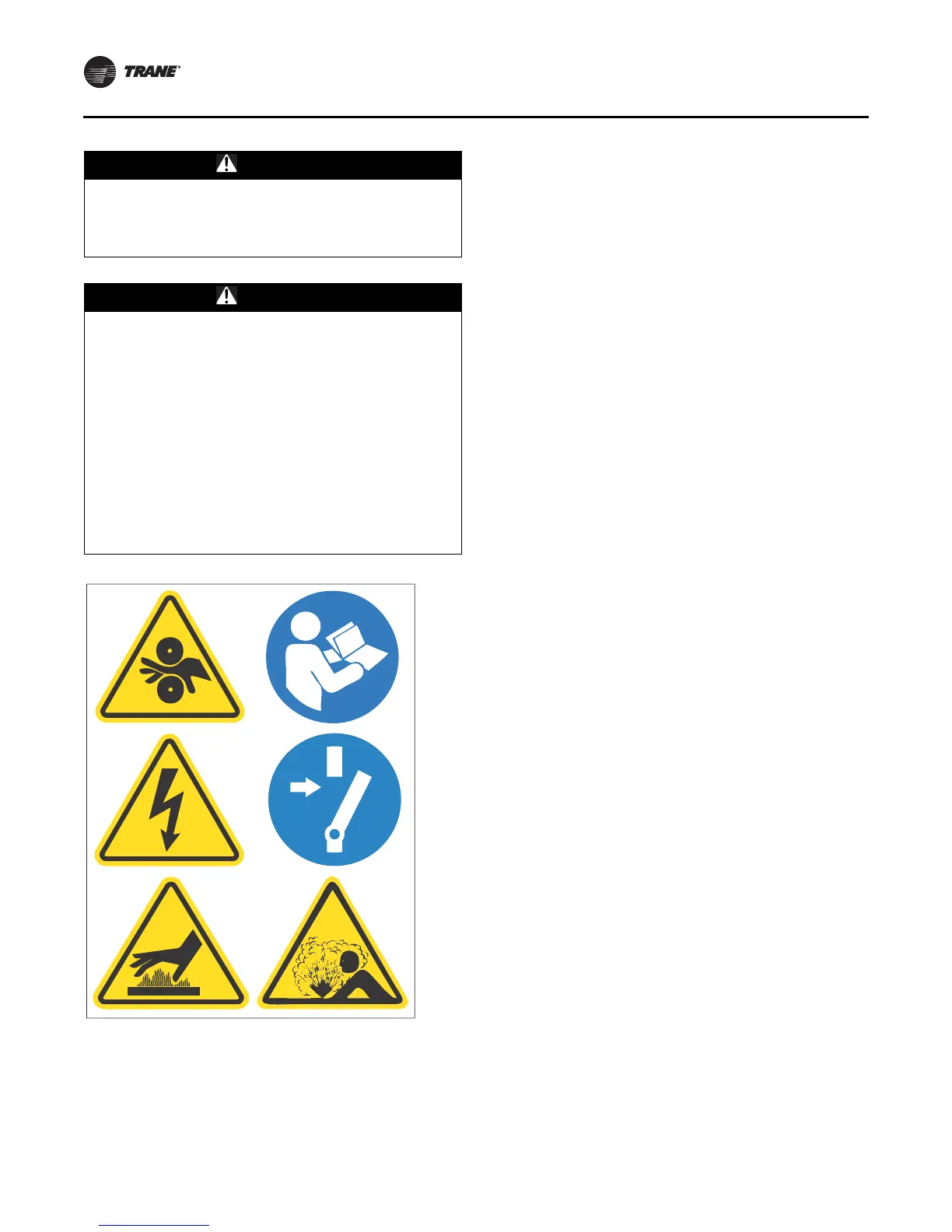

Note: Graphic labels (shown above) are used for CE

application only.

Important:

• Before servicing, disconnect all power sources and

allow at least 30 minutes for capacitors to discharge.

• All electrical enclosures—unit or remote—are IP2X.

To ensure proper lubrication and prevent refrigerant from

condensing in the oil tank, two 750-watt heaters are in

wells in the oil tank and are used to heat the oil while the

unit is off. With the default settings, the oil heaters are de-

energized when the unit starts. The heaters energize as

needed to maintain 53.3°C to 56.1°C (128°F to 133°F) when

the chiller is not running.

When the chiller is operating, the temperature of the oil

tank is typically 37.8°C to 60.0°C (100°F to 140°F). The oil

return lines are routed into a separation chamber in the oil

tank. Gas flow exits out the top of the oil tank and is vented

to the evaporator.

A dual eductor system, using high pressure condenser

gas, reclaims oil from the suction cover and the

evaporator. The suction cover eductor is discharged into

the evaporator, and the evaporator eductor is discharged

into the oil tank. The evaporator eductor line has a shut-off

valve mounted on the evaporator. Normally, the valve

should be 3/4 to one turn open. Open up to two turns if

necessary.

Oil supply to both the thrust bearing and journal bearings

is cooled when the oil tank temperature reaches 60.0°C

(140°F). The supply oil and li quid refrigerant are pumped

to a brazed plate heat exchanger. The unit controller

monitors oil tank temperature and opens a solenoid valve

to allow liquid refrigerant to flow into the heat exchanger.

Motor Cooling System

Compressor motors are cooled with liquid refrigerant (see

Figure 38, p. 69). The refrigerant pump is located on the

front of the oil tank (motor inside the oil tank). The

refrigerant pump inlet is connected to the well at the

bottom of the condenser. The well design ensures

preferential supply of liquid refrigerant to the refrigerant

pump before refrigerant is supplied to the economizer.

Refrigerant is delivered to the motor via the pump. An in-

line filter is installed (replace the in-line filter only with

major service). Motor refrigerant drain lines are routed to

the condenser.

Tracer AdaptiView Display

Information is tailored to operators, service technicians,

and owners.

When operating a chiller, there is specific information you

need on a day-to-day basis—setpoints, limits, diagnostic

information, and reports.

Day-to-day operational information is presented at the

display. Logically organized groups of information—

chiller modes of operation, active diagnostics, settings

and reports put information conveniently at your

fingertips. For more information, refer to Tr acer

AdaptiView™ Display for Water-Cooled CenTraVac™

Chillers Operations Guide (CTV-SVU01D-EN, or the most

recent version).

WARNING

Hot Surface!

Failure to use caution while working on the oil system

could result in severe burns. Oil system temperature

could exceed 65.6°C (150°F).

WARNING

Hazardous Voltage in Oil Tank Junction

Box Enclosure and Oil Pump Motor

Terminal Box!

Failure to disconnect main power and/or auxiliary

control power before opening oil tank junction box

enclosure or any other junction box/terminal box/panel

on the CVHH and CDHH chiller can result in death or

serious injury. Apply lockout/tagout devices and follow

all company procedures for lockout/ tagout. Unit must

be tested to ensure a zero energy state and equipment

must be put in an electrically safe work condition prior

to maintenance. Hazardous voltage up to 600 Vac is

present in the oil tank junction box enclosure and oil

pump motor terminal box.

Loading...

Loading...