Power Supply Wiring

CVHH-SVX001A-EN 53

• Customers are responsible for all field wiring with

respect to EMC and EMI interference. Customers are

responsible to mitigate the risks associated with EMC

and EMI interference that can occur as a result of

customer-provided field wiring as dictated by

international, national, and local codes. This also

implies that for remote-mounted starters and drives,

customers are responsible for the entire field wiring

into the starter/drive as well as between the starter/

drive and the chiller/compressor terminals with

respect to EMC and EMI interference. It also implies

that customers are responsible for incoming power

wiring to both the starter/drive and CPTR option

enclosure unit-mounted panel with respect to EMC

and EMI interference.

All customer wiring, including power wiring to starters/

drives/CPTR Option/UPS shore power, needs to be

separated: 24–27 Vdc, 110–120 Vac, and 380–600 Vac each

need to be in separate conduit runs.

For 110/120V customer wiring, including power supply to

CPTR option, it is required that the customer provides

some sort of surge protection and all customer wiring

needs to be run in flexible metal conduit and grounded at

both ends.

For remote starters interfacing with the Trane chiller, all

wiring needs to be run in flexible metal conduit and

grounded at both ends. Any ethernet cables being used by

customer to interface with the Trane chiller must be

shielded ethernet cabling.

The customer is required to provide an overcurrent

protective device upstream of all starters and drives in

accordance with IEC standards and/or any applicable local

and national codes.

Service personnel must use proper PPE for servicing and

should also use proper lockout/tagout procedures during

servicing: lock the starter disconnect handle before

servicing to prevent accidental pulling of disconnect

handle at the starter panel. In addition, service personnel

should first disconnect the main supply disconnecting

device upstream of the starter or drive before performing

any service on any part of the chiller.

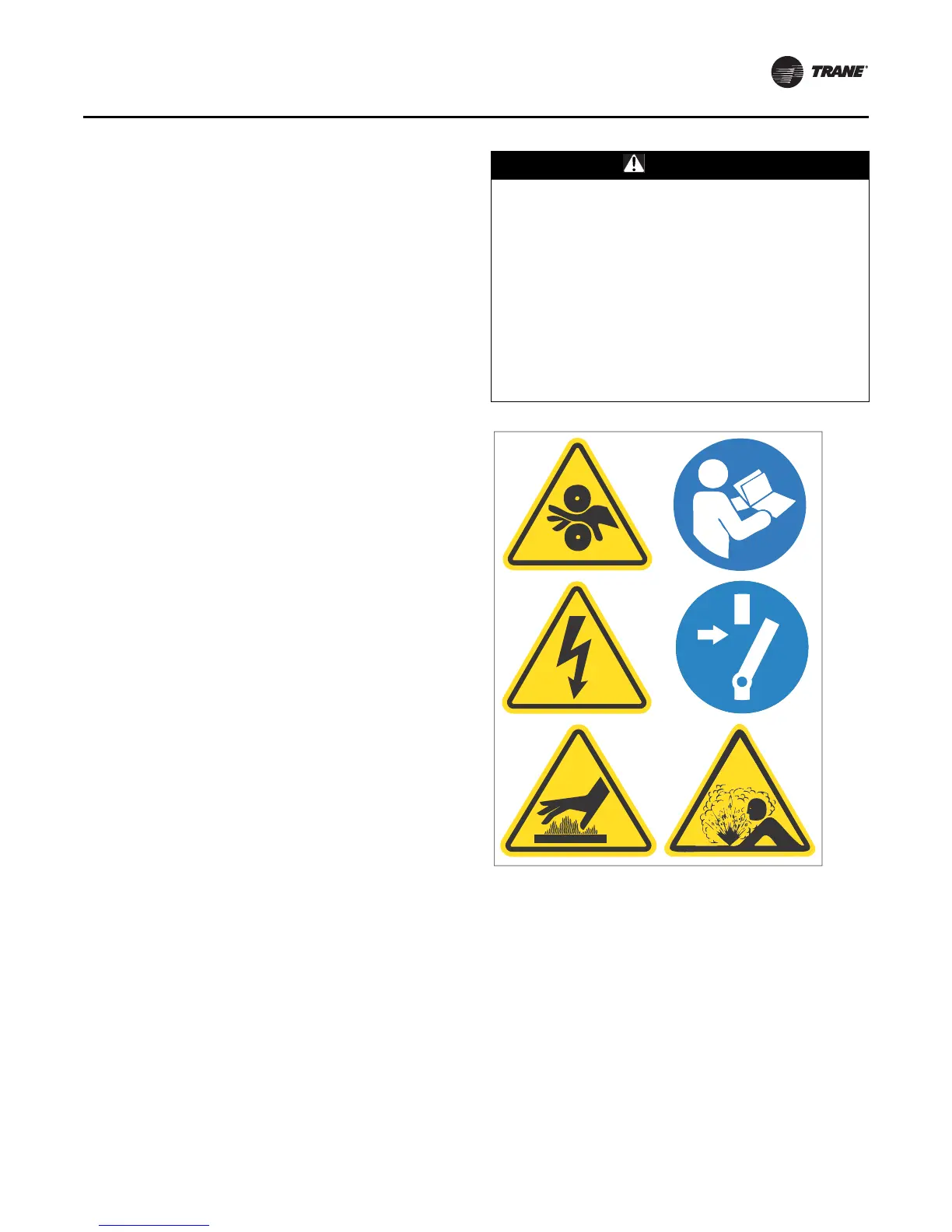

Note: Graphic labels (shown above) are used for CE

application only.

Important:

• Before servicing, disconnect all power sources and

allow at least 30 minutes for capacitors to discharge.

• All electrical enclosures—unit or remote—are IP2X.

For CE units, the convenience outlet in the control panel

requires a suitable adaptor to m eet the needs of customers

with different plug requirements.

WARNING

Lockout/Tagout Before Removing Touch-

Safe Covers!

Failure to follow instructions regarding touch-safe

covers could result in death or serious injury. Touch-safe

covers inside panels are there for protection and may

be removed if necessary for service only and only after

disconnection of main power supply. Before removing

any touch-safe cover, ensure that there is no line power

first. Removal of touch-safe covers would be at the

customer/ service personnel’s own risk. After any

service is completed, if the touch-safe covers have been

removed, the touch-safe covers need to be put back in

to ensure safety and protection.

Loading...

Loading...