Start-up and Shut-down

86 CVHH-SVX001A-EN

The purge condensing-unit compressor suction

temperature varies with the amount of non-condensables

collected in the purge tank. If the amount of non-

condensables collected in the purge tank limits the

available condensing surface in the tank, the condensing-

unit compressor suction temperature begins to fall.

The purge controller initiates a pump-out cycle when the

suction temperature reaches the pump-out initiate value

that is calculated within the purge control. During the

pump-out cycle, the sm all pump-out compressor pulls any

non-condensables from the purge tank and discharges

them through the carbon tank. As the non-condensables

are removed from the purge tank, the condensing-unit

compressor suction temperature increases. The purge

controller monitors the compressor suction temperature

and cycles or stops the pump-out, depending on the

temperature that is present.

The 1/4 hp air-cooled condensing unit of the refrigeration

system operates effectively when it is in the operating

range shown in

Figure 50.

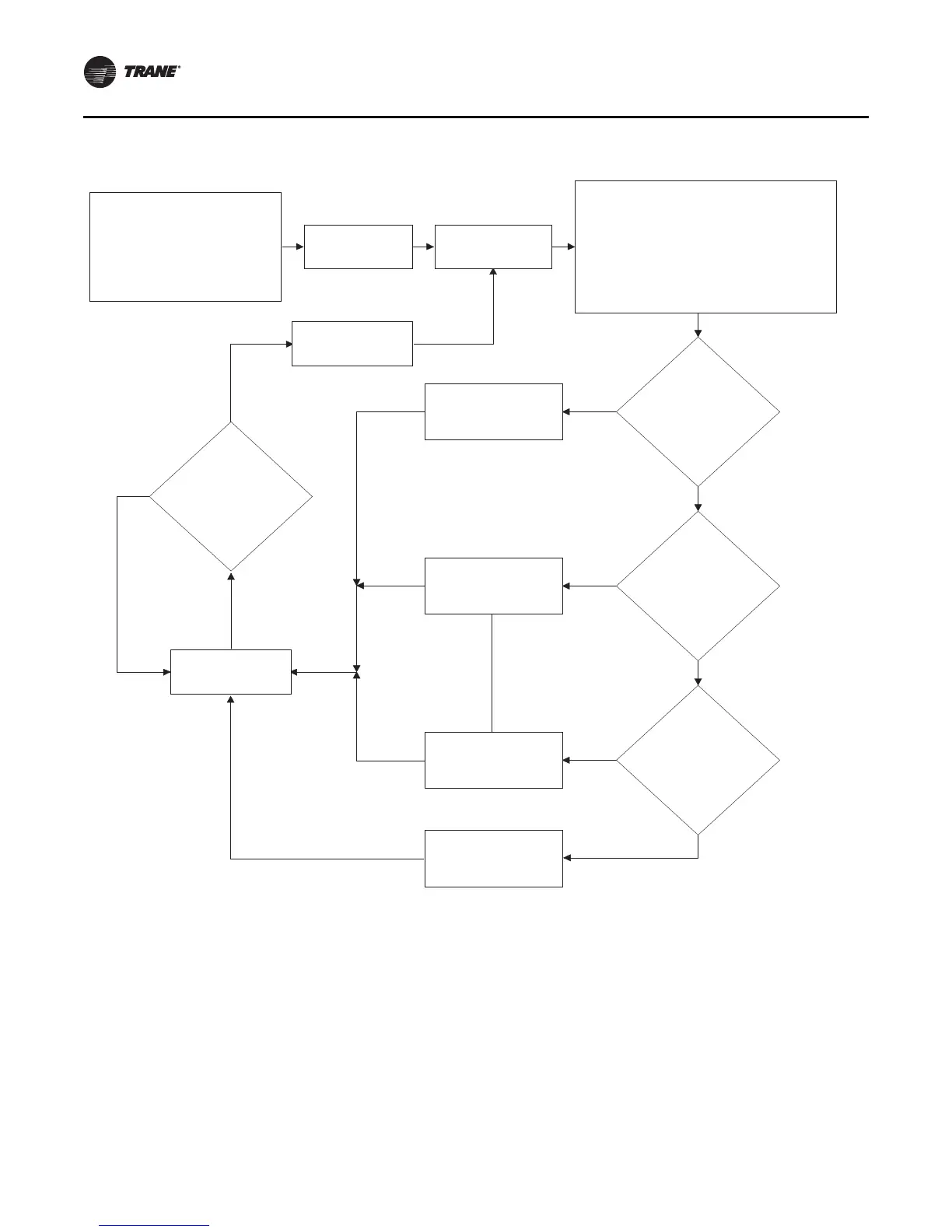

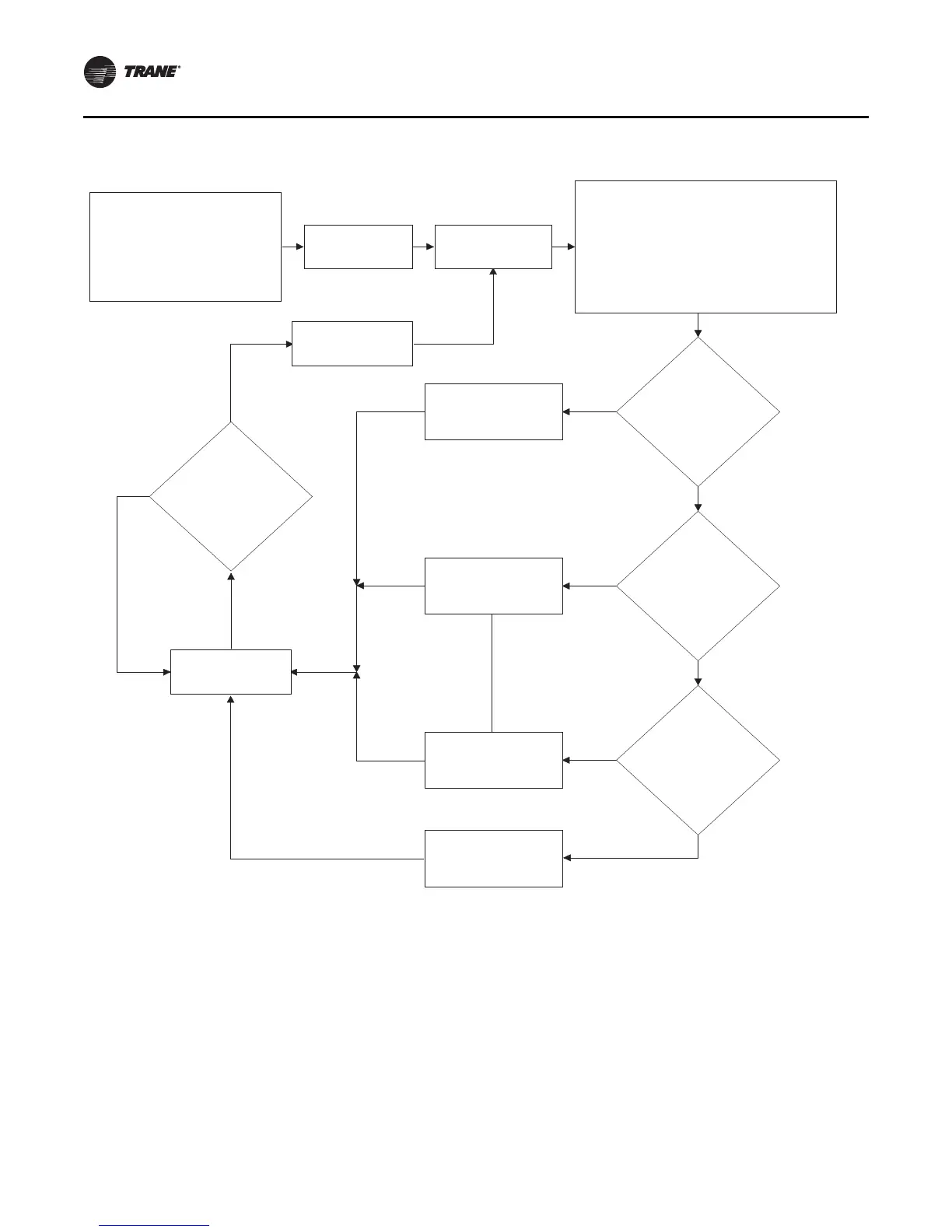

Figure 49. Adaptive chiller OFF flow chart

First chiller power-up.

Purge operates

continuously for 168

hours to collect data.

Chiller On or Off.

Chiller Off. Purge Off.

The purge control reviews the historical

pump-out data for “chiller On” and

“ chiller Off” an d det er m ines the Pum pout

Time (from the last 24 hrs, or the daily

average over the last 7 days, whichever

is greater).

Turn purge Off.

Hold purge Off for

6 hours.

Hold purge Off for

1 day.

Hold purge Off for

2 days.

Hold purge Off for

3 days.

Is Pumpout

Tim e less than

5 minutes?

Is Pumpout

Tim e less t han

3 minutes?

Is Pumpout

Tim e less t han

1 minute?

Is purge run

60 minutes

without

purging?

Run purge.

Yes

Yes

Yes

Yes

No

No

No

No

Loading...

Loading...