Start-up and Shut-down

90 CVHH-SVX001A-EN

If the carbon tank temperature exceeds 120 percent of the

regeneration temperature setpoint, the controller issues a

latching diagnostic, Purge Carbon Regeneration

Temperature Limit Exceeded. The purpose of this

diagnostic is to identify a failed heater relay or

temperature sensor. It disables the purge and opens the

exhaust solenoid valve.

If the carbon tank temperature does not increase more

than 13.3°C (56°F) in the fi rst two hours, the controller

generates a non-latching diagnostic, Carbon Regeneration

Temperature Too Low. The purpose of this diagnostic is to

identify a failed heater or temperature sensor. It prevents

automatic regeneration from occurring, but a service

technician can initiate a manual regeneration for testing

purposes. All other purge algorithms continue to function.

If the carbon tank temperature does not reach the

minimum regeneration temperature setpoint within 4

hours, the controller generates a non-latching diagnostic,

Purge Carbon Regen Temperature Not Satisfied. The

purpose of this diagnostic is to identify a failing insulation

system.

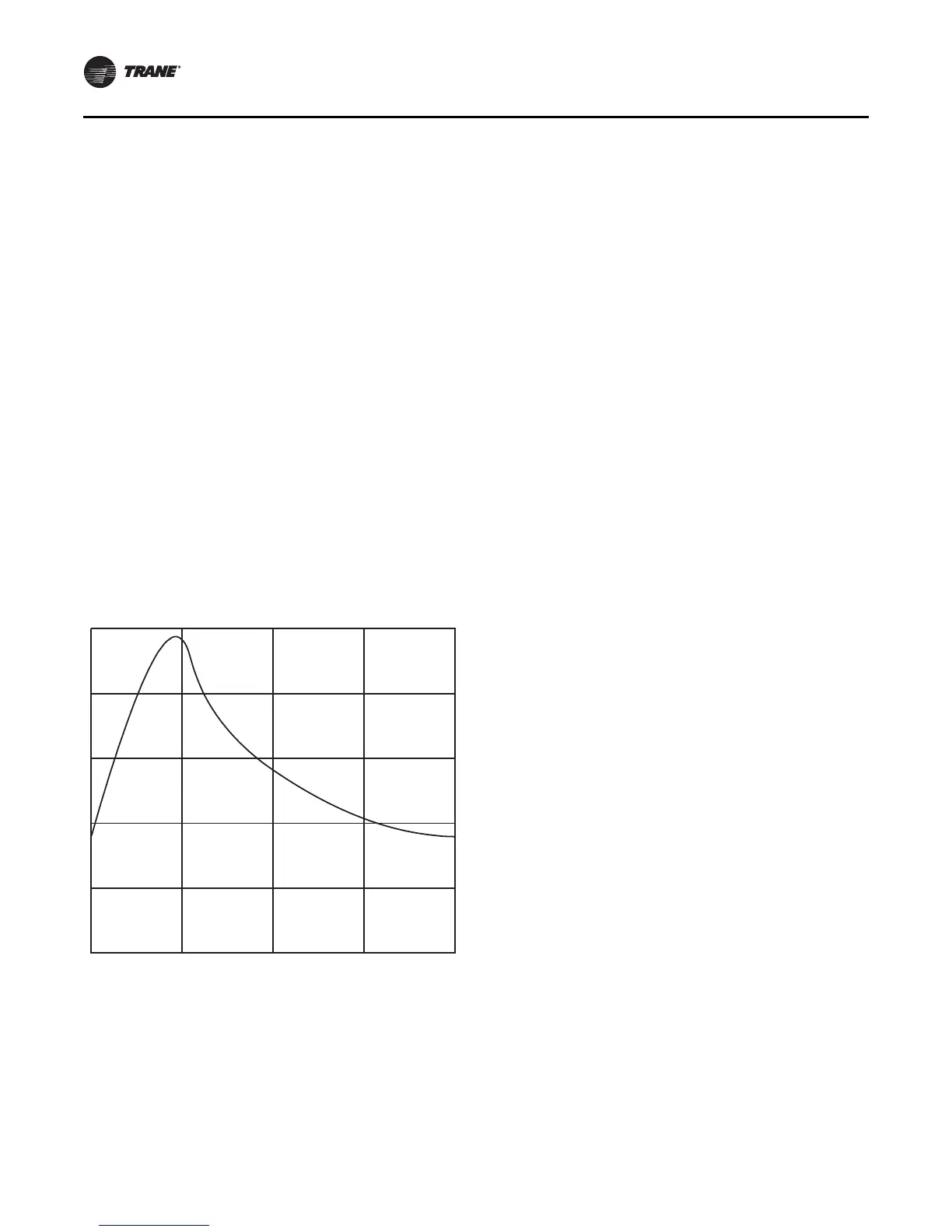

The complete regeneration cycle can take as long as seven

hours to accomplish, but an average chiller does not have

to regenerate very often. A typical regeneration cycle is

depicted in

Figure 51.

Purge Status Points

The status points appear on the purge component screen

of the Tracer AdaptiView display. The purge component

screen is accessible from the purge touch target on the

home screen of the display.

Time Until Next Purge Run. Displayed if the purge is

in Adaptive mode and is idle. It indicates the amount of

time left on the adaptive cycle timer.

Daily Pumpout—24 Hours. Indicates the daily

pumpout time for the last 24 hours (a moving 24-hour

window). It indicates how the hermetic integrity of the

chiller compares to historic pump-out times for the same

chiller. It also allow s a check against factory-recommended

values.

Average Daily Pumpout—7 Days. Indicates the

average daily pump-out time for the last 168 hours (a

moving 168-hour window). Enables a comparison of

present pump-out times to past averages, and can be

another indication of the hermetic integrity of the chiller.

Daily Pumpout Limit/ Alarm. Indicates the limit value

that an operator has set in the Settings menu. When the

daily pumpout rate exceeds this value, purge operation

stops and a diagnostic is generated.

Chiller On—7 Days. Indicates the percentage of time

during the past 7 days (floating 168-hour window) that the

chiller was operating. You can use it to help determine if a

leak is present on the high side or the low side of the chiller.

Pumpout Chiller On—7 Days. Indicates the

percentage of the total purge pump-out time during the

past 7 days that occurred while the chiller was operating.

You can use it to help determine if a leak is present on the

high side or the low side of the chiller.

Pumpout Chiller Off—7 Days. Indicates the

percentage of the total purge pump-out time during the

past 7 days that occurred when the chiller was not

operating. You can use it to help determine if a leak is

present on the high side or the low side of the chiller.

Pumpout—Life. Indicates the total purge pump-out

time that has accumulated over the life of the purge.

Purge Rfgt Cprsr Suction Temp. Indicates the purge

refrigerant compressor suction temperature. It is useful

for diagnosing purge system problems.

Purge Liquid Temp. Indicates the temperature sensed

by the controller and used to inhibit purge operation. The

purge liquid temperature sensor, when the chiller is

operating, is the chiller saturated condenser temperature

sensor; when the chiller is Off, it is the chiller saturated

evaporator temperature sensor. If this temperature is

below the Pumpout Inhibit Temperature that is defined in

the Settings menu, pump out is not allowed. This value is

used to prevent inefficient operation of the purge under

certain conditions.

Carbon Tank Tem p. Indicates the carbon bed

tem perature and is useful for monitoring regeneration and

for diagnosing regeneration system problems.

Figure 51. Typical carbon regeneration cycle

Loading...

Loading...