Recommended Maintenance

CVHH-SVX001A-EN 97

1. Follow all instructions in “ Waterbox Removal and

Installation,” p. 98

to remove waterbox covers.

2. Work a round nylon or brass bristled brush (attached to

a rod) in and out of each of the condenser water tubes

to loosen the sludge.

3. Thoroughly flush the condenser water tubes with clean

w ater.

Scale deposits are best removed by chemical means.

Be sure to consult any qualified chemical house in the

area (one familiar with the local water supply’s

chemical mineral content) for a recommended

cleaning solution suitable for the job.

Note: A standard condenser water circuit is

composed solely of copper, cast iron, and steel.

Important: All of the materials used in the external

circulation system, the quantity of the

solution, the duration of the cleaning

period, and any required safety precautions

should be approved by the company

furnishing the materials or performing the

cleaning. Remember, however, that

whenever the chemical tube cleaning

method is used, it must be followed up with

mechanical tube cleaning, flushing and

inspection.

Evaporator

Since the evaporator is typically part of a closed circuit, it

may not accumulate appreciable amounts of scale or

sludge. Normally, cleaning every three years is sufficient.

However, periodic inspection and cleaning is

recommended on open evaporator systems, such as air

washers.

Waterbox and Tubesheet Protective Coatings

Trane recommends that coated waterboxes/tubesheets—

regardless of the type of protective coating included—be

taken out of service within the first one to three months of

operation for inspection. Any voids or defects identified

upon inspection must be repaired. If the water quality is

known to be highly supportive of corrosion (i.e., sea water,

etc.), inspect the coating system at one month; if the water

quality is known to be relatively benign (i.e., normal

treated and clean condenser water), inspect the coating

system within three months. Only when initial inspections

show no problems are present should subsequent

maintenance intervals be increased.

Sacrificial Anodes

The replacement schedule for the optional zinc or

magnesium anodes can vary greatly with the

aggressiveness of the water that is in the system. Some

sites could require anode replacement every two to three

months while other sites may require anode replacement

every two to three years. Trane recommends that anode

inspection for wear sometime within the first several

months of the anodes being placed into service. If the

observed loss of anode material is small, then the interval

between subsequent inspections can be lengthened.

Replace the anode and/or shorten the inspection interval if

the anode has lost 50 percent or more of its original mass.

If anode depletion occurs very quickly, consult a water

treatment specialist to determine if the anode material

selected is correct for the application.

As needed after draining the waterbox, use a 63.5 mm (2-1/

2 in.) wrench to remove/install Trane-supplied waterbox

anodes.

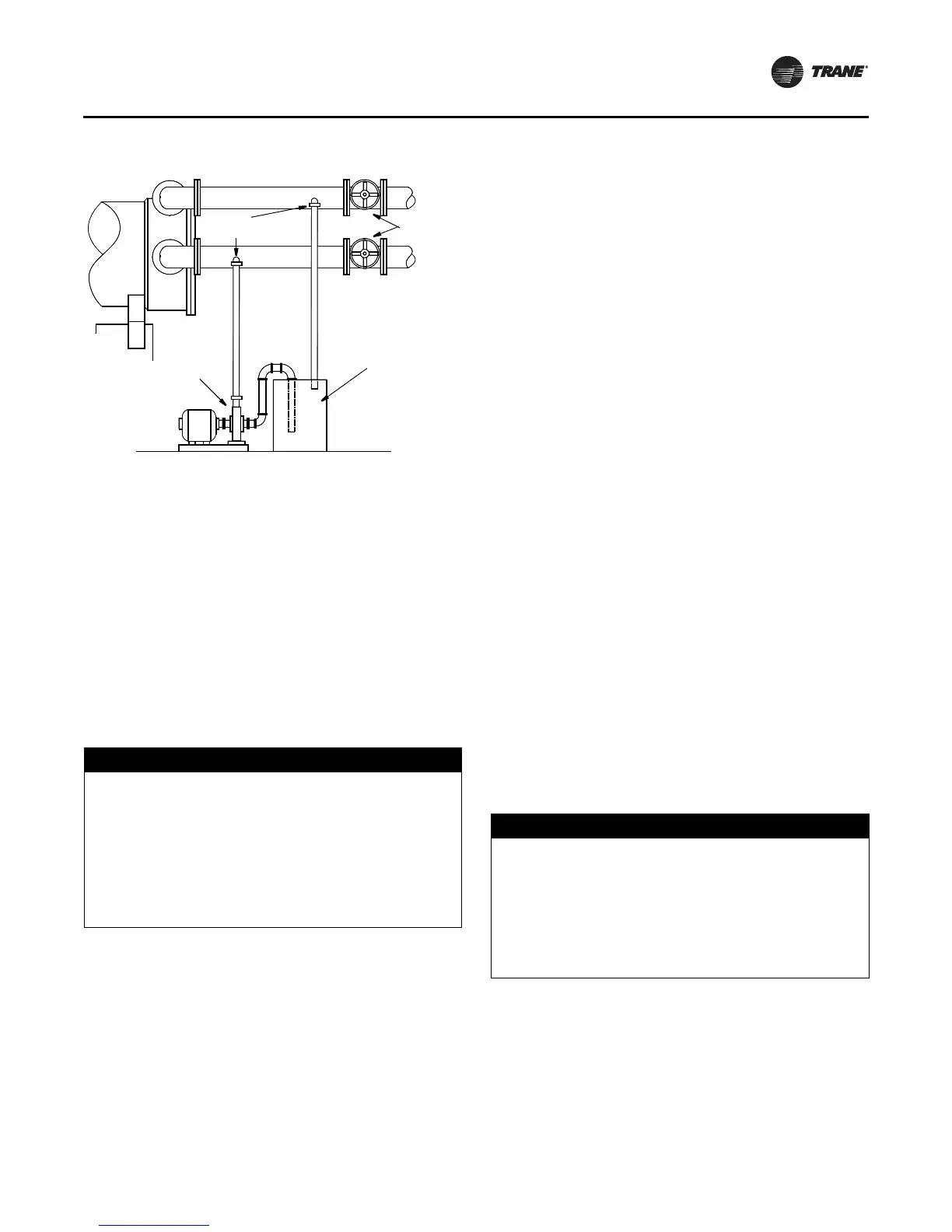

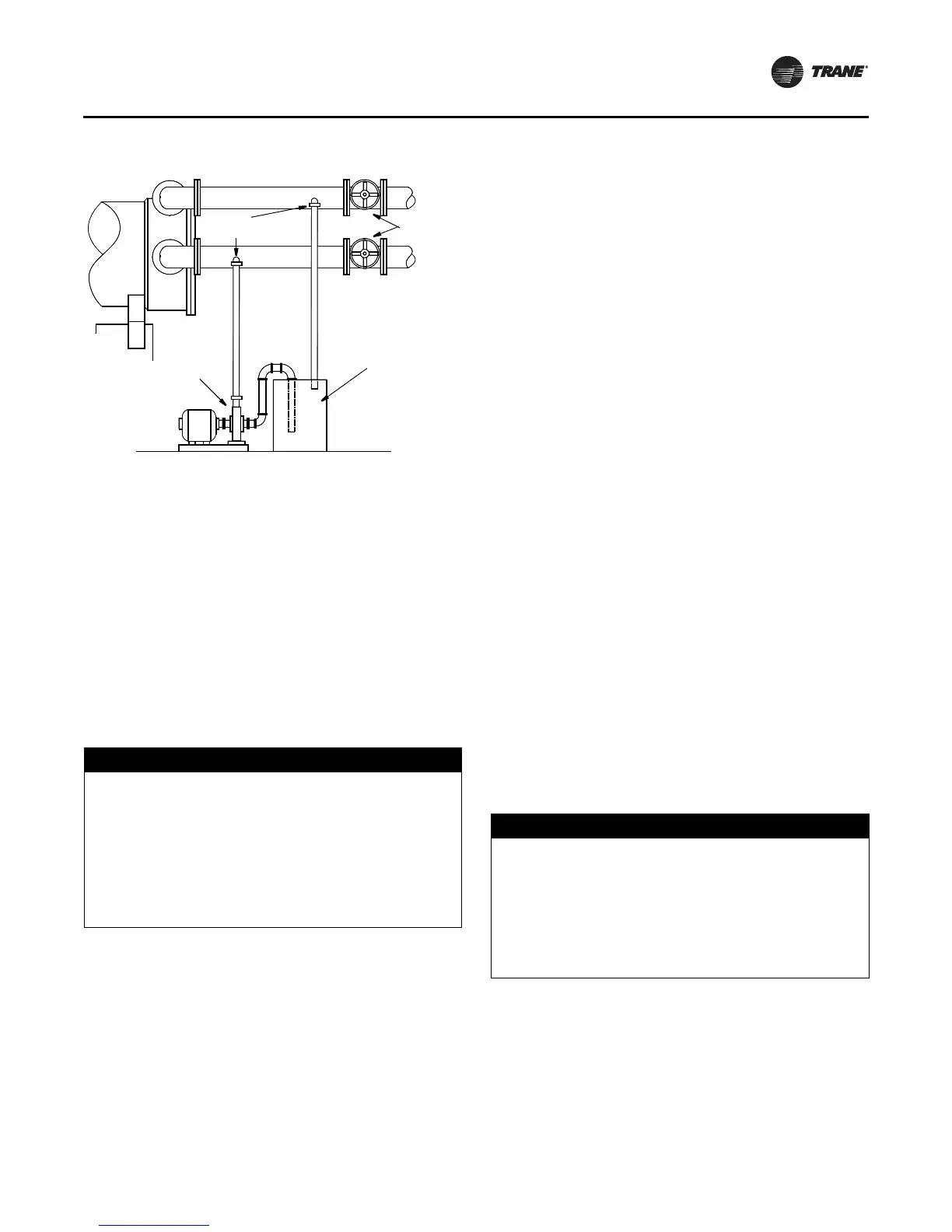

Figure 53. Typical chemical cleaning setup

NOTICE:

Unit Corrosion Damage!

Failure to follow proper procedures when using

corrosive chemicals to clean water side of unit could

result in corrosion damage to the unit and tubes. It is

recommended that the services of a qualified chemical

cleaning firm be used. Proper personal protective

equipment as recommended by the chemical

manufacturer should be used. Refer to the chemicals

MSDS sheet for proper safety procedures.

pipe

connections

circulator

pump

cleaning

solution

shutoff

valves

NOTICE:

Equipment Damage!

Failure to follow instructions could result in equipment

damage. Do NOT use Teflon-based tape or paste on

anode; a small amount of liquid sealant (Loctite

®

242 or

equivalent) may be applied to prevent leakage when

installing an anode, but do not apply so much sealant

that it prevents the necessary electrical connection

between the anode and the waterbox.

Loading...

Loading...