CHECKING OIL CLEARANCE BETWEEN CRANK PINS AND CRANK

PIN

BEARINGS

1.

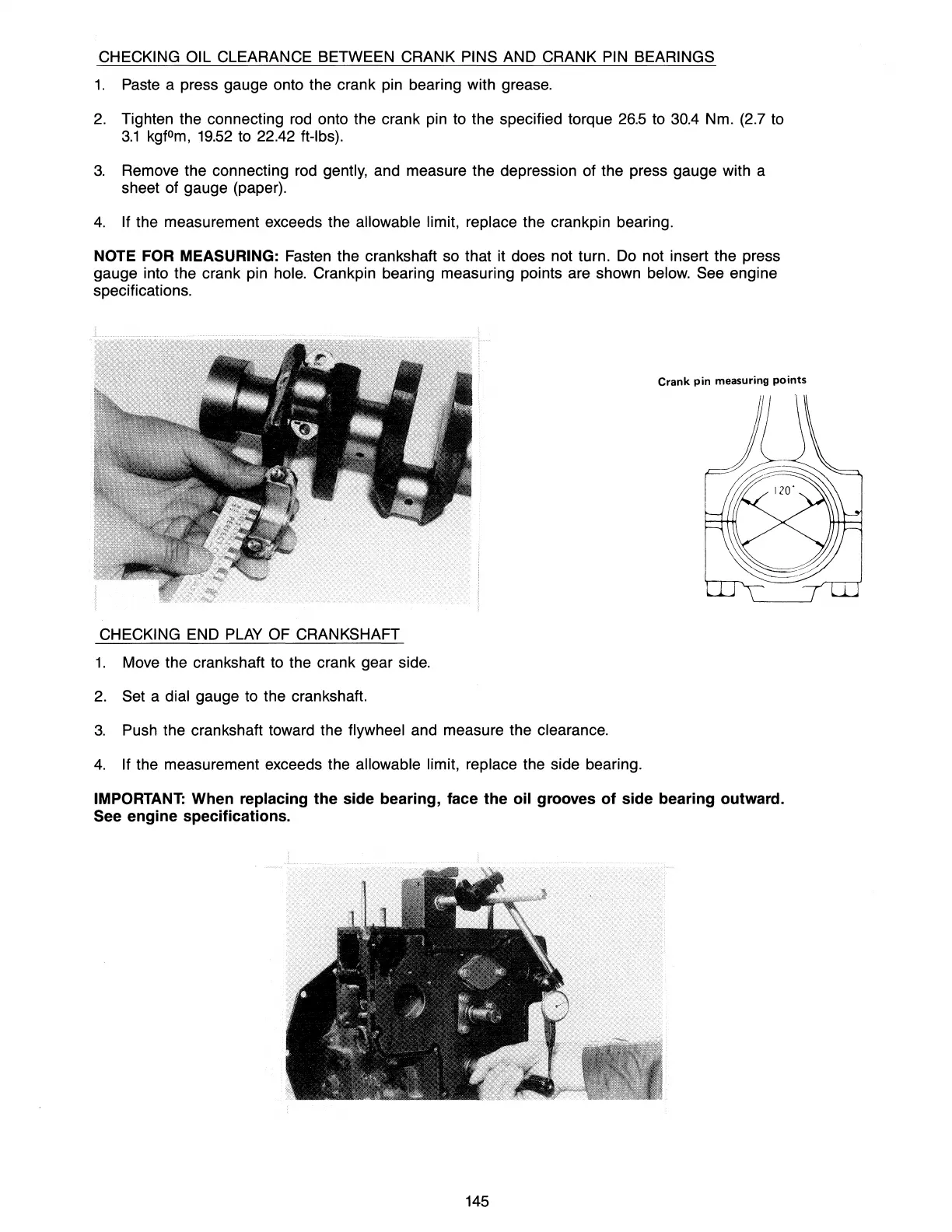

Paste a press gauge onto the crank pin bearing with grease.

2.

Tighten the connecting

rod

onto the crank pin to the specified torque

26.5

to

30.4

Nm. (2.7 to

3.1

kgfOm,

19.52

to 22.42 ft-Ibs).

3.

Remove the connecting

rod

gently, and measure the depression of the press gauge with a

sheet of gauge (paper).

4.

If the measurement exceeds the allowable limit, replace the crankpin bearing.

NOTE FOR MEASURING: Fasten the crankshaft so that it does not turn.

Do

not insert the press

gauge into the crank pin

hole. Crankpin bearing measuring points are shown below. See engine

specifications.

Crank pin measuring

points

CHECKING END

PLAY

OF CRANKSHAFT

1.

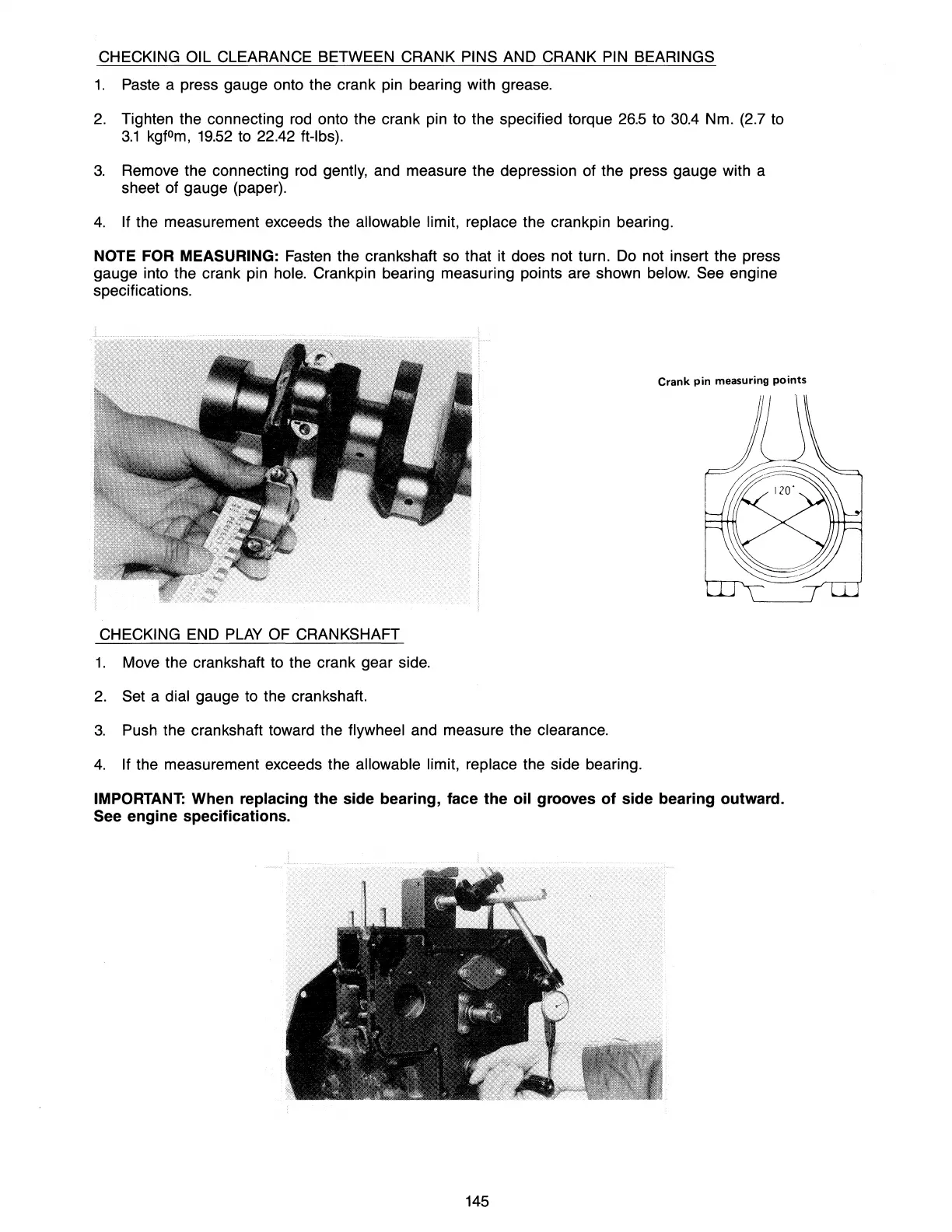

Move the crankshaft to the crank gear side.

2.

Set a dial gauge to the crankshaft.

3.

Push the crankshaft toward the flywheel and measure the clearance.

4.

If the measurement exceeds the allowable limit, replace the side bearing.

IMPORTANT: When replacing

the

side bearing, face

the

oil

grooves

of

side

bearing outward.

See engine specifications.

145

Loading...

Loading...