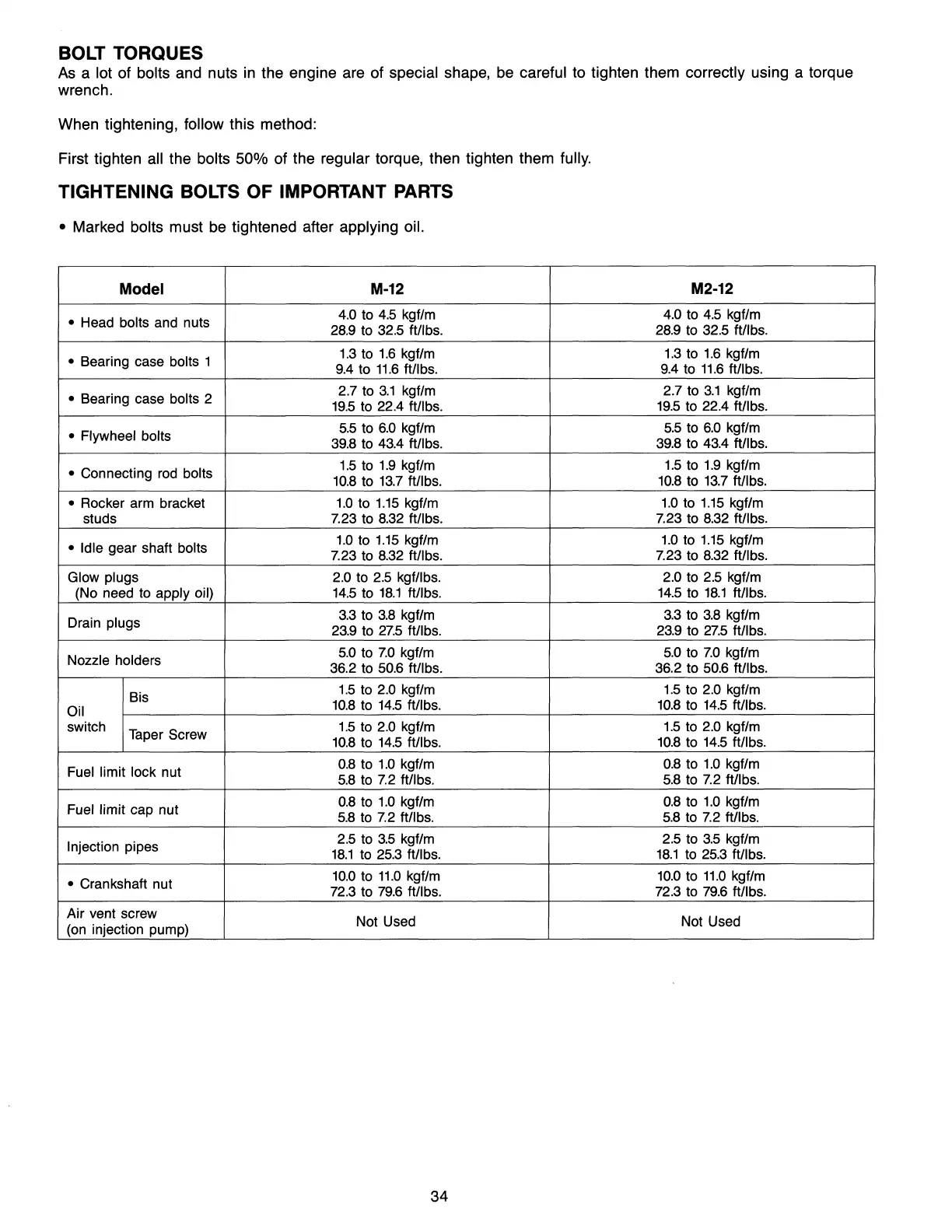

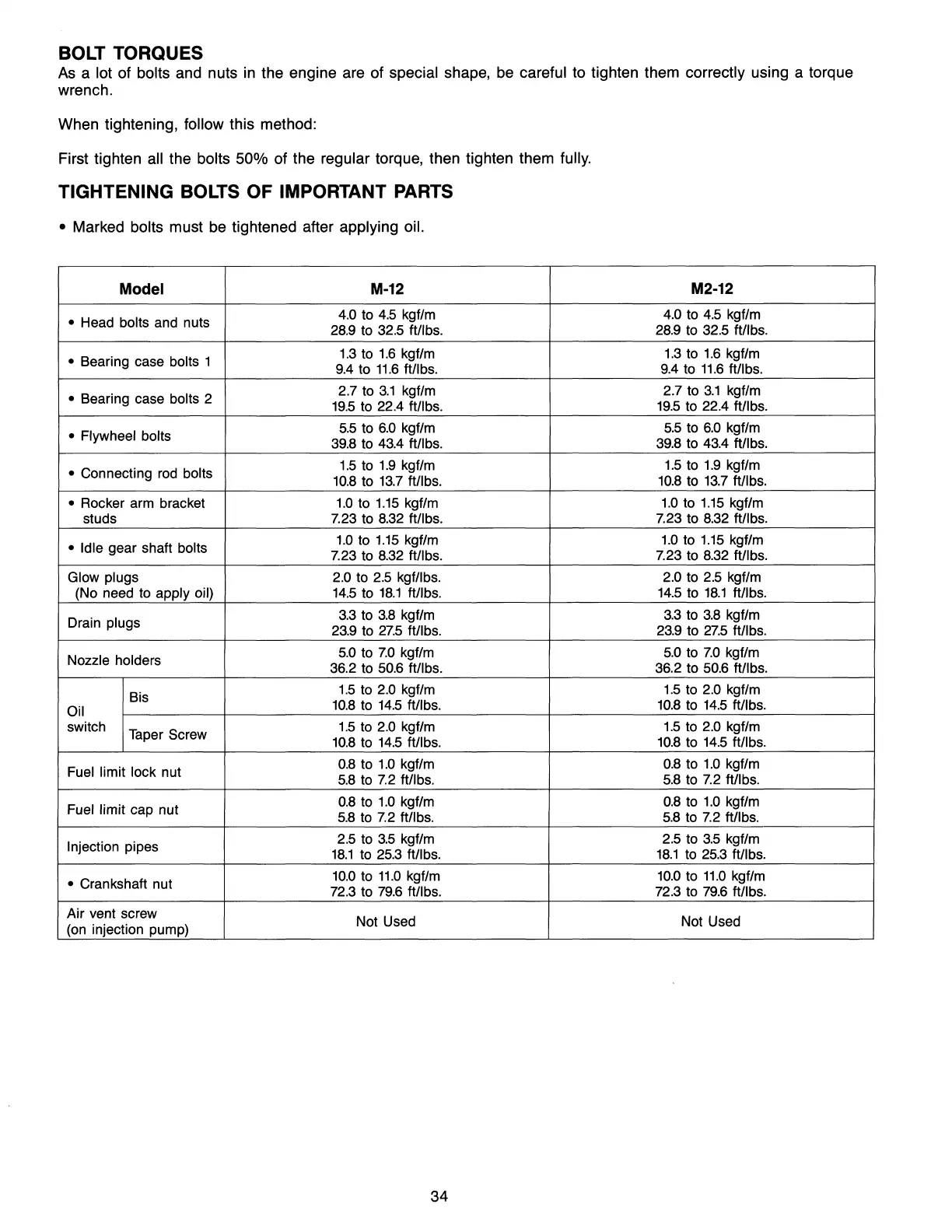

BOLT TORQUES

As a lot of bolts and nuts

in

the engine are of special shape,

be

careful

to

tighten them correctly using a torque

wrench.

When tightening,

follow this method:

First tighten

all the bolts 50% of the regular torque, then tighten them fully.

TIGHTENING BOLTS OF IMPORTANT PARTS

• Marked bolts must

be

tightened after applying oil.

Model

M-12 M2-12

• Head bolts and nuts

4.0

to

4.5

kgf/m

4.0

to

4.5

kgf/m

28.9

to 32.5 ft/lbs.

28.9

to 32.5 ftllbs.

•

Bearing case bolts 1

1.3

to

1.6

kgf/m

1.3

to

1.6

kgf/m

9.4

to

11.6

ft/lbs.

9.4

to

11.6

ft/lbs.

•

Bearing case bolts 2

2.7 to

3.1

kgf/m 2.7 to

3.1

kgf/m

19.5

to 22.4 ftllbs.

19.5

to 22.4 ft/lbs.

• Flywheel bolts

5.5

to

6.0

kgf/m

5.5

to

6.0

kgf/m

39.8

to 43.4 ftllbs.

39.8

to 43.4 ftllbs.

•

Connecting

rod

bolts

1.5

to

1.9

kgf/m

1.5

to

1.9

kgf/m

10.8

to

13.7

ft/lbs.

10.8

to

13.7

ft/lbs.

•

Rocker arm bracket

1.0

to

1.15

kgf/m

1.0

to

1.15

kgf/m

studs

7.23

to

8.32

ft/lbs. 7.23 to

8.32

ft/lbs.

• Idle

gear shaft bolts

1.0

to

1.15

kgf/m

1.0

to

1.15

kgf/m

7.23 to

8.32

ft/lbs. 7.23 to

8.32

ft/lbs.

Glow plugs

2.0 to

2.5

kgf/lbs. 2.0 to 2.5 kgf/m

(No need to

apply oil)

14.5

to

18.1

ft/lbs.

14.5

to

18.1

ft/lbs.

Drain plugs

3.3

to

3.8

kgf/m

3.3

to

3.8

kgf/m

23.9

to

27.5

ftllbs.

23.9

to

27.5

ftllbs.

Nozzle holders

5.0

to

7.0

kgf/m

5.0

to

7.0

kgf/m

36.2 to

50.6

ftllbs. 36.2 to

50.6

ftllbs.

Bis

1.5

to

2.0

kgf/m

1.5

to 2.0 kgf/m

Oil

10.8

to

14.5

ft/lbs.

10.8

to

14.5

ftllbs.

switch

Taper Screw

1.5

to 2.0 kgf/m

1.5

to

2.0

kgf/m

10.8

to

14.5

ftllbs.

10.8

to

14.5

tt/lbs.

Fuel limit lock

nut

0.8

to

1.0

kgf/m

0.8

to

1.0

kgf/m

5.8

to

7.2

ft/lbs.

5.8

to

7.2

ftllbs.

Fuel limit

cap nut

0.8

to

1.0

kgf/m

0.8

to

1.0

kgf/m

5.8

to

7.2

ft/lbs.

5.8

to

7.2

ft/lbs.

Injection

pipes

2.5

to

3.5

kgf/m

2.5 to

3.5

kgf/m

18.1

to

25.3

tt/l

bs.

18.1

to

25.3

ftllbs.

•

Crankshaft nut

10.0

to

11.0

kgf/m

10.0

to

11.0

kgf/m

72.3

to

79.6

ft/lbs.

72.3 to

79.6

ft/lbs.

Air vent screw

Not Used Not Used

(on

injection pump)

34

Loading...

Loading...