Section

4-2 LX 31/41 Work Platform

Maintenance

4.1

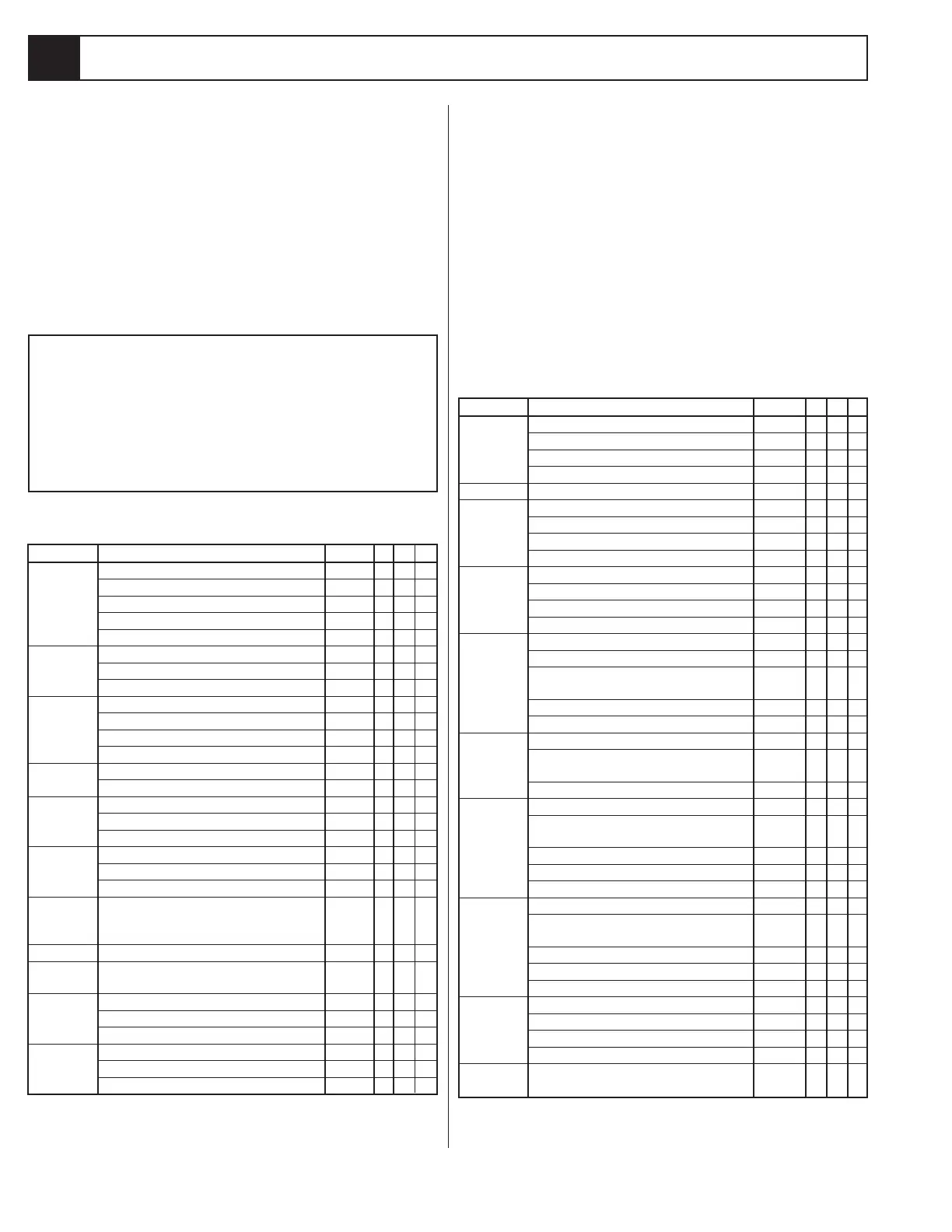

Preventative Maintenance Table Key

Interval

Daily=each shift or every day

50h/30d=every 50 hours or 30 days

250h/6m=every 250 hours or 6 months

1000h/2y=every 1000 hours or 2 years

Y=Yes/Acceptable

N=No/Not Acceptable

R=Repaired/Acceptable

Preventative Maintenance Report

Date: _______________________________________

Owner: ______________________________________

Model No: ___________________________________

Serial No: ____________________________________

Serviced By: __________________________________

Service Interval: _______________________________

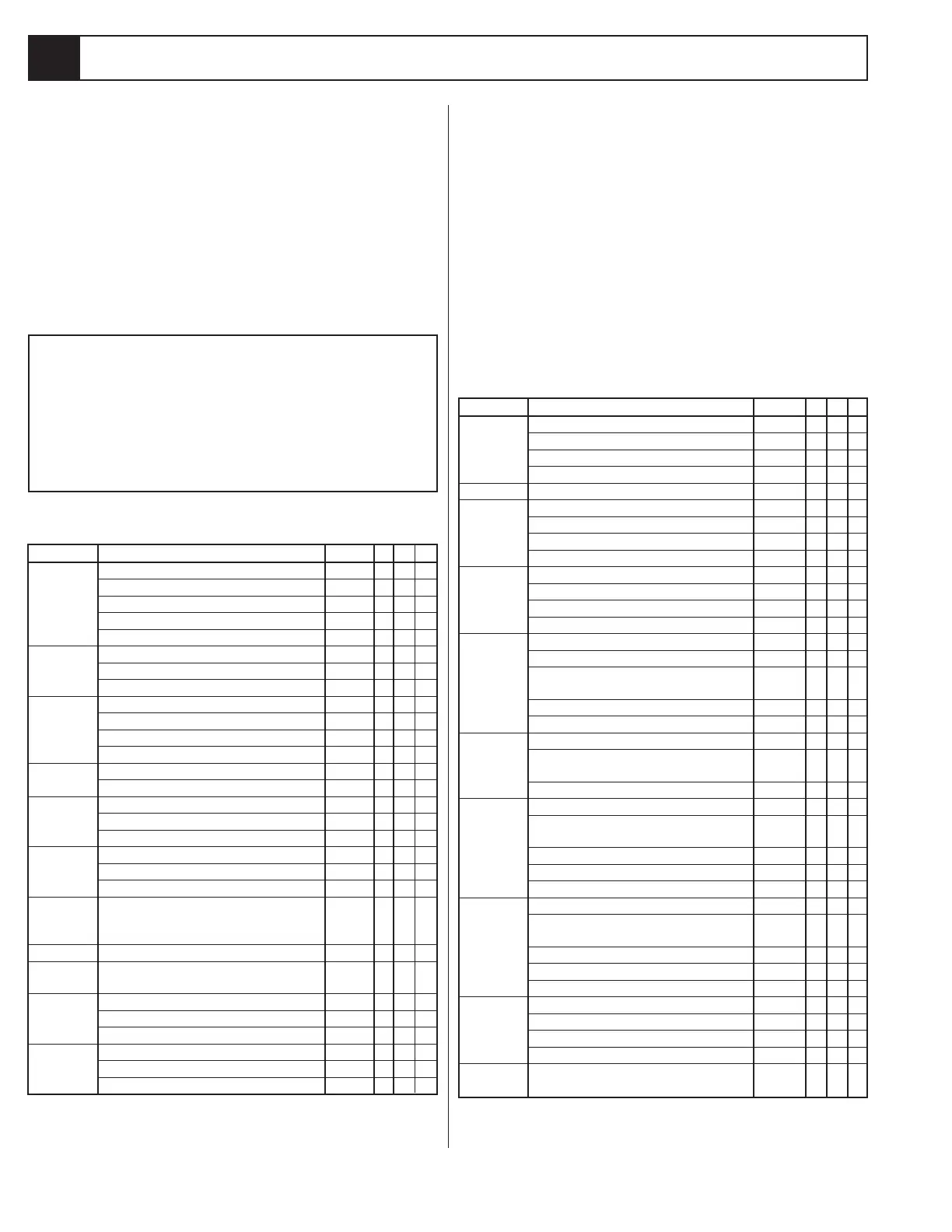

Table 4-1: Preventative Maintenance Checklist

COMPONENT INSPECTION OR SERVICES INTERVAL Y N R

Battery Check electrolyte level 6

M

Check specific gravity 6

M

Clean exterior 6

M

Check battery cable condition Daily

Clean terminals 6

M

Engine Oil Check level and condition Daily

and Check for leaks Daily

Filter Change oil filter 100

H

Engine Fuel Check fuel level Daily

System Check for leaks Daily

Replace fuel filter 6

M

Check air cleaner Daily

Engine Check coolant level (with engine cold) Daily

Coolant Replace coolant 3

M

Hydraulic Check oil level Daily

Oil Change filter 6

M

Drain and replace oil 2

Y

Hydraulic Check for leaks Daily

System Check hose connections 30

D

Check hoses for exterior wear 30

D

Emergency Operate the emergency lowering Daily

Hydraulic valve and check for serviceability

System

Controller Check switch operation Daily

Control Check the exterior of the cable Daily

Cable for pinching, binding or wear

Platform Check fasteners for proper torque Daily

Deck and Check welds for cracks Daily

Rails Check condition of deck Daily

Tires Check for damage Daily

Check air pressure (50 psi [3.4 bar]) Daily

Check lug nuts (torque to 90 ft. lbs. [123 Nm]) 30

D

COMPONENT INSPECTION OR SERVICES INTERVAL Y N R

Hydraulic Wipe clean 30

D

Pump Check for leaks at mating surfaces 30

D

Check for hose fitting leaks Daily

Check mounting bolts for proper torque 30

D

Drive Motors Check for operation and leaks Daily

Torque Check for leaks Daily

Hubs Check Oil level 250

H

/6

M

Change Oil after break-in 50

H

/30

D

Change Oil 1000h/2y

Steering Check hardware & fittings for proper torque 6

M

System Grease pivot pins 30

D

Oil king pins 30

D

Check steering cylinder for leaks 30

D

Elevating Inspect for structural cracks Daily

Assembly Check pivot points for wear 30

D

Check mounting pin pivot bolts 30

D

for proper torque

Check elevating arms for bending 6

M

Grease linkage pins 30

D

Chassis Check hoses for pinch or rubbing points Daily

Check component mounting 6

M

for proper torque

Check welds for cracks Daily

Lift Check the cylinder rod for wear 30

D

Cylinder Check mounting pin pivot bolts 30

D

for proper torque

Check seals for leaks 30

D

Inspect pivot points for wear 30

D

Check fittings for proper torque 30

D

Axle Check the cylinder rod for wear 30

D

Cylinder Check mounting pin pivot bolts 30

D

for proper torque

Check seals for leaks 30

D

Inspect pivot points for wear 30

D

Check fittings for proper torque 30

D

Entire Check for and repair collision damage Daily

Unit Check fasteners for proper torque 3

M

Check for corrosion-remove and repaint 6

M

Lubricate 30

D

Labels Check for peeling, missing, or Daily

unreadable labels & replace

Table 4-1: Preventative Maintenance Checklist (cont'd.)

Loading...

Loading...