Section

4-4 LX 31/41 Work Platform

Maintenance

4.3 Battery Maintenance

Hazard of explosive gas mixture. Keep

sparks, flame, and smoking material away

from battery.

Always wear safety glasses when working

with batteries.

Battery fluid is highly corrosive. Thoroughly

rinse away any spilled fluid with clean

water.

BATTERY INSPECTION AND

CLEANING

Check battery fluid level daily, especially if work plat-

form is being used in a warm, dry climate. If required,

add distilled water ONLY. Use of tap water with high

mineral content will shorten battery life.

The battery and cables should be inspected regularly for

signs of cracks in the case, electrolyte leakage and

corrosion of the terminals. Inspect cables for worn spots

or breaks in the insulation and for broken cable termi-

nals.

Clean the battery when it shows signs of corrosion at the

terminals or when electrolyte has overflowed during

charging. Use a baking soda solution to clean the

battery, taking care not to get the solution inside the

cells. Rinse thoroughly with clean water. Clean battery

and cable contact surfaces to a bright metal finish

whenever a cable is removed.

4.4

4.4 Lubrication

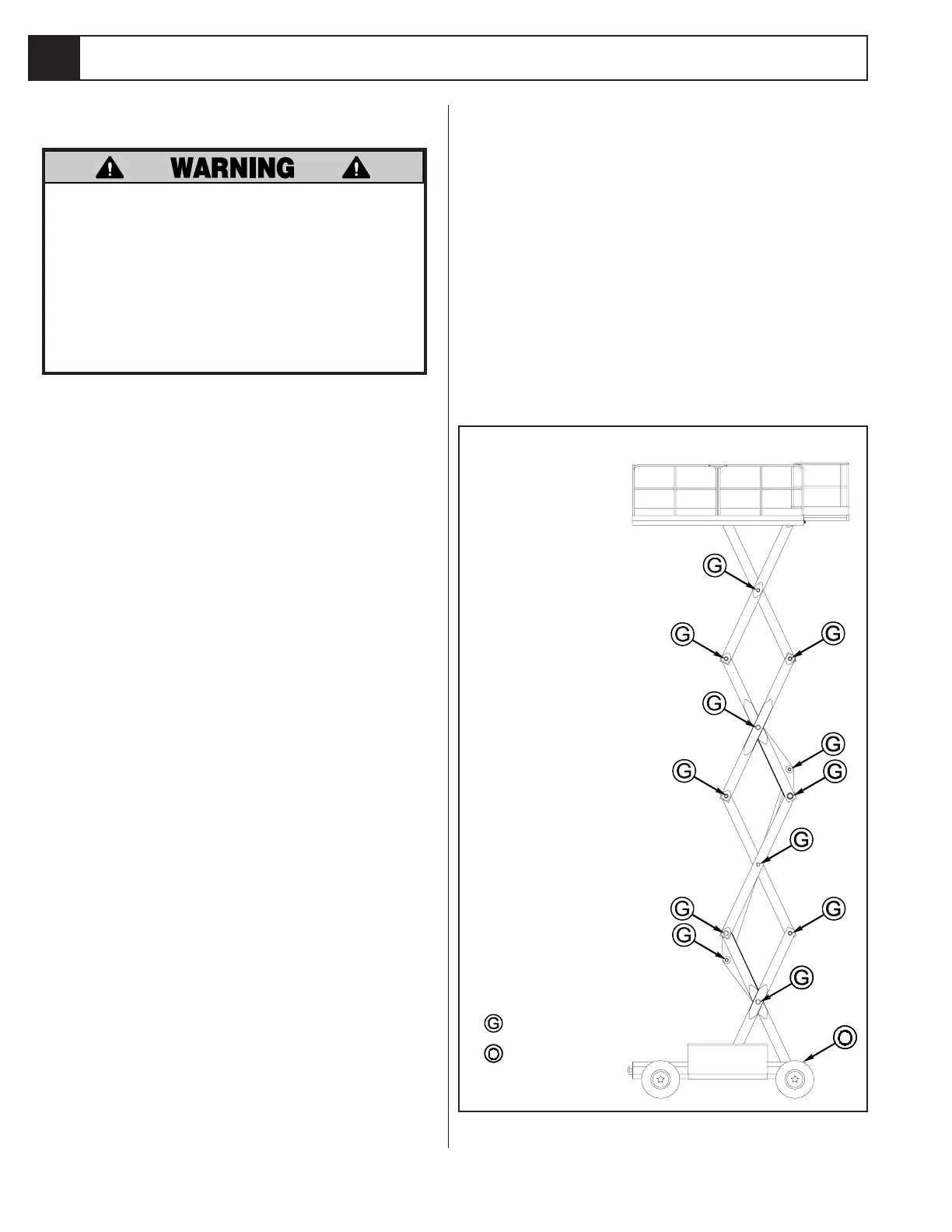

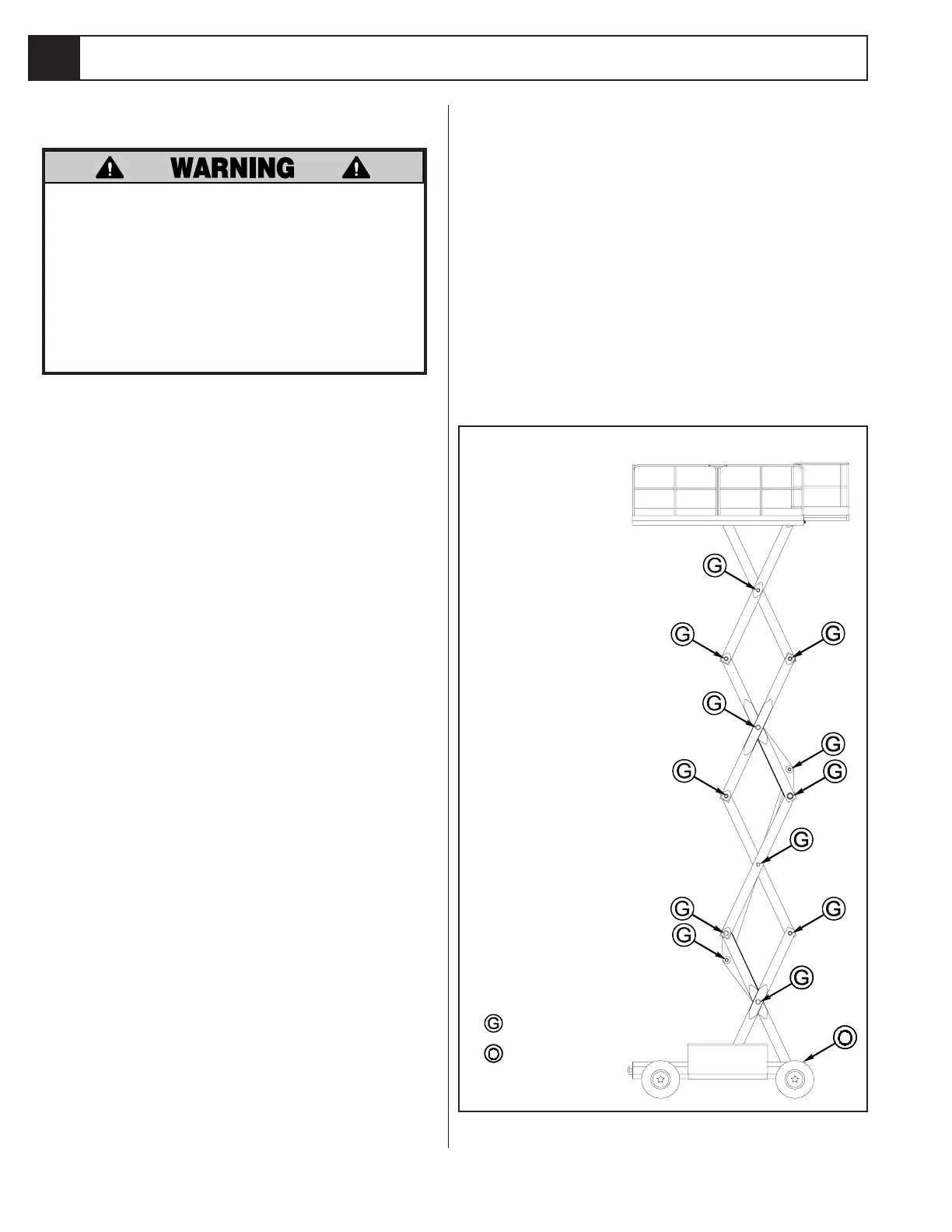

Refer to Table 4-1 for the lubrication intervals and

Figure 4-2 for location of items that require lubrication

service. Refer to the appropriate sections for lubrication

information on the Steering Linkage, Torque hubs,

Hydraulic Oil and Filter, and Engine Oil and Filter.

GREASE FITTINGS

Wipe each grease fitting before and after greasing. Using

multipurpose grease in a grease gun, pump the grease

into the fitting until grease just begins to appear at the

edges of the pivot, wipe off any excess grease.

STEERING LINKAGE

Apply one or two drops of penetrating oil to each pivot

and King Pin bearing.

TORQUE HUBS

Note: Change oil in torque hubs after the first 50

hours of operation. Change every 1000 hours there-

after.

1. Remove Torque Hub from rear drive assembly (refer

to section 4.9).

2. Remove drain plug from underside of Torque Hub.

3. Drain oil from unit.

4. Replace drain plug.

5. Remove fill plug from top side of torque hub.

6. Fill unit with 90 wt. gear oil.

7. Replace fill plug.

Figure 4-2: Lubrication Chart

Grease

Oil

Loading...

Loading...