Section

4-7LX 31/41 Work Platform

Maintenance

4.5

9. Remove the gauge and replace the cap. Replace

the Green/White wire to terminal 17. Lower the

machine off of the jackstands.

STEERING RELIEF VALVES

1. Operate the hydraulic system 10 to 15 minutes to

warm the oil.

2. Install a 0-3000 P.S.I. gauge at the Main Pressure

Test Port.

3. Loosen the locknut or remove the cap on the Left

Steer Relief Valve.

4. Turn the adjustment screw two full turns counter-

clockwise.

5. Press the Steering Switch to the left and hold until

the system bypasses.

6. Turn the Steering Relief Valve adjustment screw

clockwise until the gauge reads 1500 P.S.I.

7. Tighten locknut or replace cap on Left Steering

Relief Valve.

8. Repeat process for Right Steering Relief Valve

BIDIRECTIONAL RELIEF VALVES

Note: Check or reset Drive Motor Relief Valves only

if you suspect that one of the Rear Wheels is not

turning due to premature bypass. This condition is

rare and Bidirectional Relief Valves should not be

reset as part of normal maintenance.

1. Operate the hydraulic system 10-15 minutes to

warm the oil.

2. Remove the cap and install a 0-3000 P.S.I. pressure

gauge at the Main Pressure Test Port.

3. Remove the Bidirectional Relief Valve from under

the rear drive motor and exchange with the Lift

Relief Valve.

4. Remove the cap from the Bidirectional Relief Valve

and turn the adjustment screw two full turns coun-

terclockwise.

5. Depress the Throttle Button and the Raise Button to

lift the platform to full height and hold until system

bypasses.

6. Turn the adjustment screw clockwise until the

pressure reaches 3000 P.S.I.

7. Replace the cap and return the Bidirectional Relief

Valve and the Lift Relief Valve to their original

positions.

8. Repeat as necessary for the other Bidirectional Relief

Valve.

9. Remove the gauge and replace the Test Port Cap.

7. Replace the cap, or tighten the locknut on the Lift

Relief Valve, and remove the load from the plat-

form.

COUNTERBALANCE VALVES

1. Operate the hydraulic system 10 to 15 minutes to

warm the oil.

2. Elevate the Front (4WD only), and Rear Wheels to

allow them to spin freely, and place on jackstands

suitable to support the weight of the machine.

3. Remove the Green/White wire from terminal 17 in

the Control Panel Assembly.

4. Install a 0-1000 P.S.I. pressure gauge at the Forward

Drive Pressure Test Port.

5. Loosen the locknut on the Reverse Counterbalance

Valve, push the control handle FORWARD, and

adjust the valve until the gauge reads 800 P.S.I.

(CW to decrease P.S.I., CCW to increase P.S.I.)

Tighten the locknut.

6. Install a 0-1000 P.S.I. pressure gauge at the Reverse

Drive Pressure Test Port.

7. Loosen the locknut on the Forward Counterbalance

Valve, push the control handle REVERSE, and adjust

the valve until the gauge reads 800 P.S.I. (CW to

decrease P.S.I., CCW to increase P.S.I.) Tighten the

locknut.

8. Recheck the pressures and adjust as necessary.

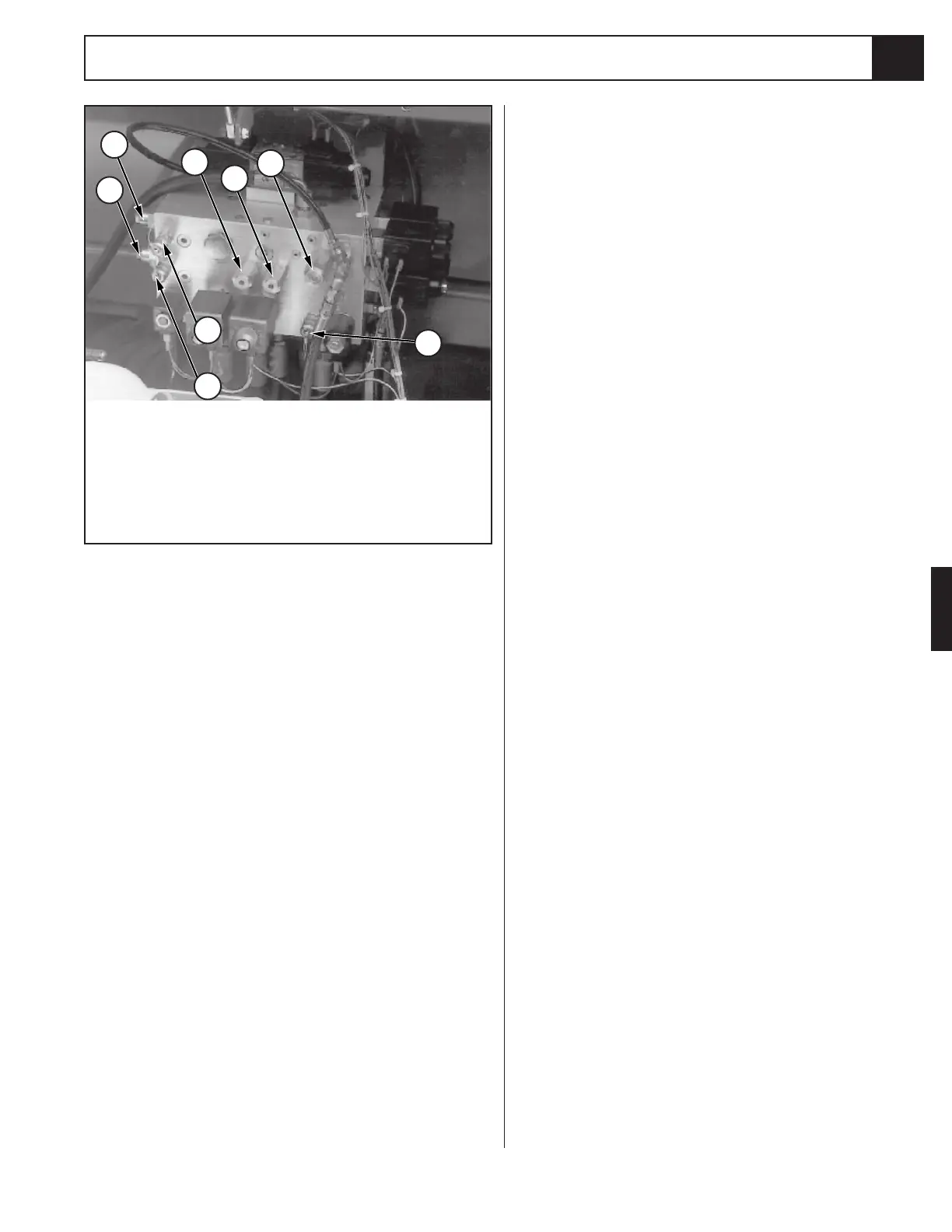

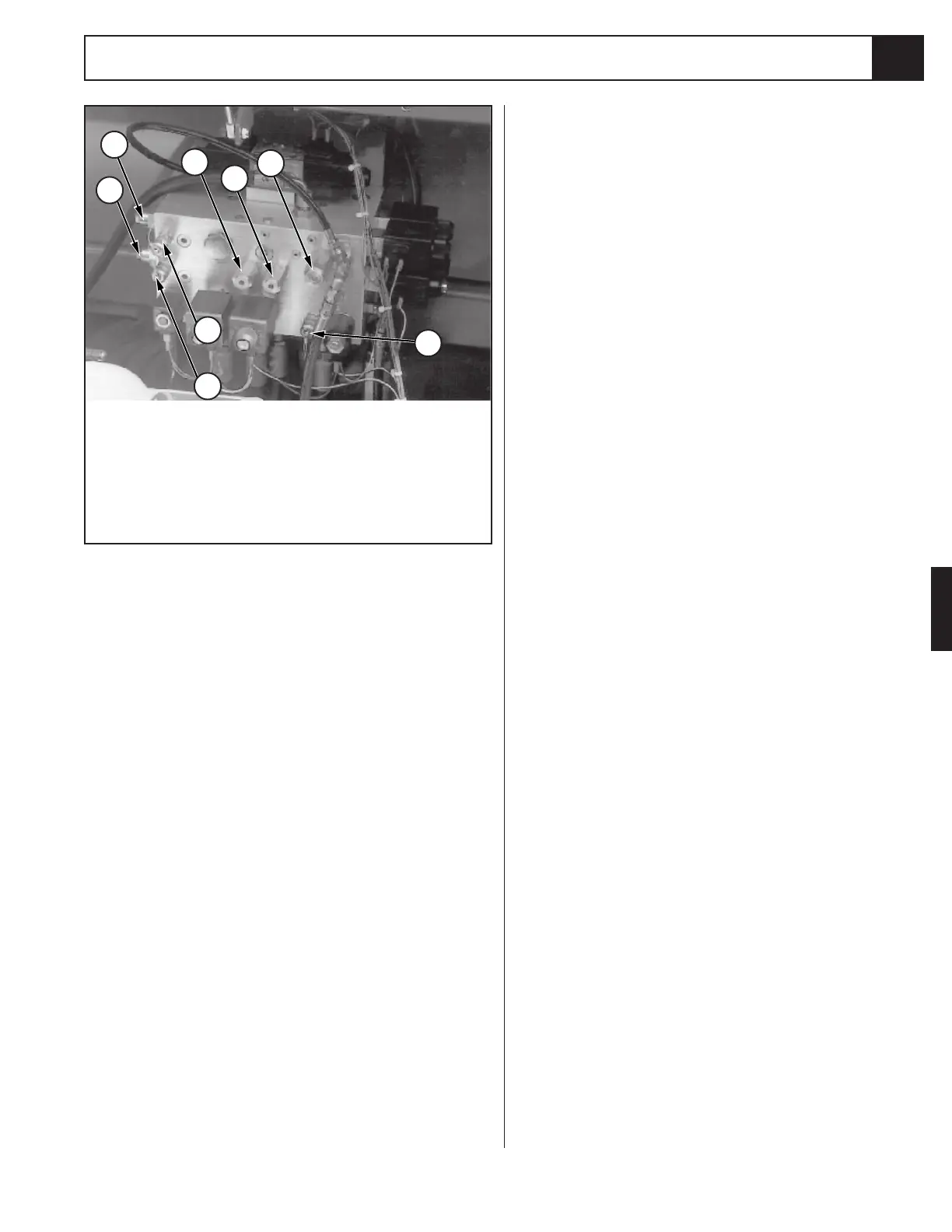

Figure 4-7: Valve Manifold

1

2

3

4

5

6

7

8

1. FWD Counter Balance Valve

2. REV Counter Balance Valve

3. FWD Drive PSI Test Port

4. REV Drive PSI Test Port

5. Steer Right Relief Valve

6. Steer Left Relief Valve

7. Lift Relief Valve

8. Main PSI Test Port

Loading...

Loading...