Section

4-13LX 31/41 Work Platform

Maintenance

4.9

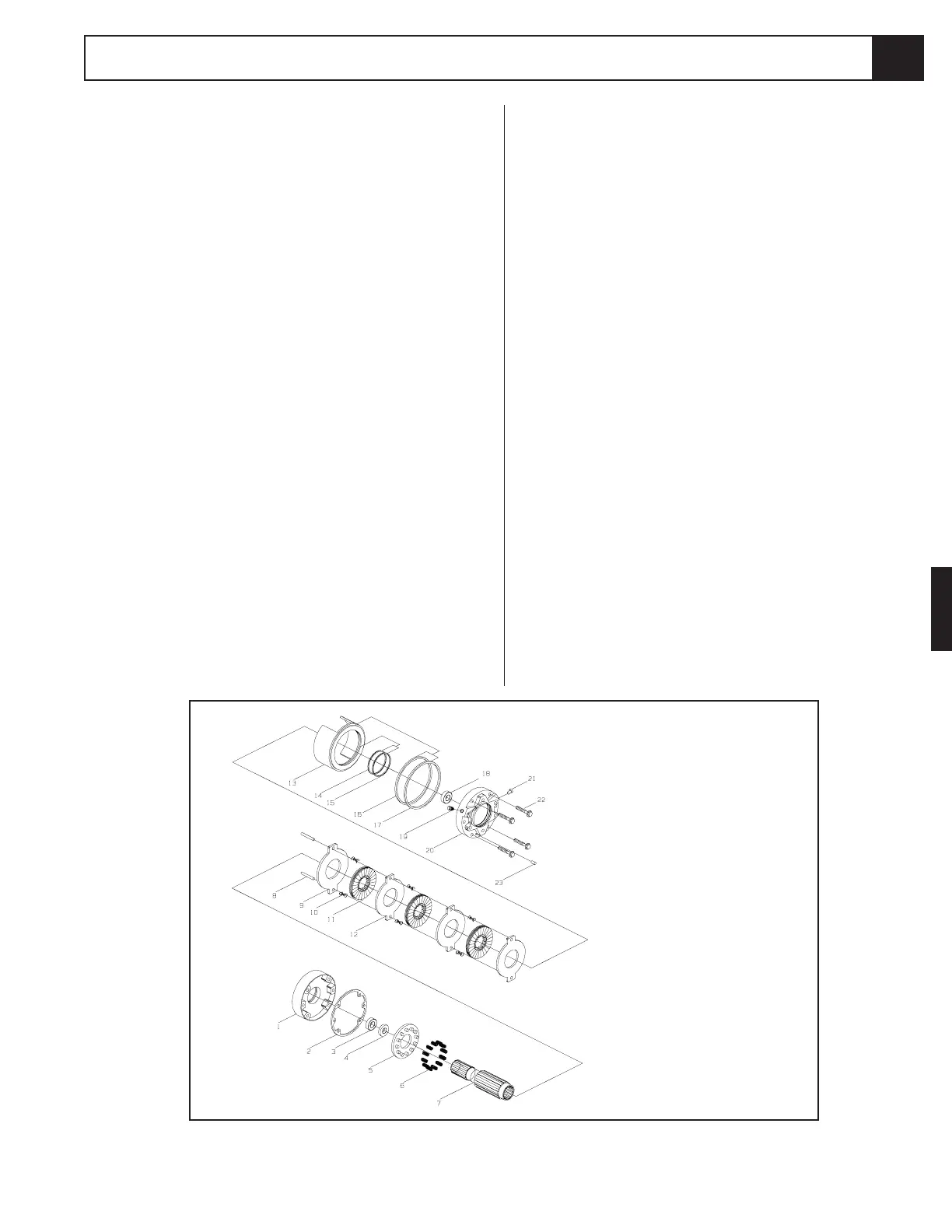

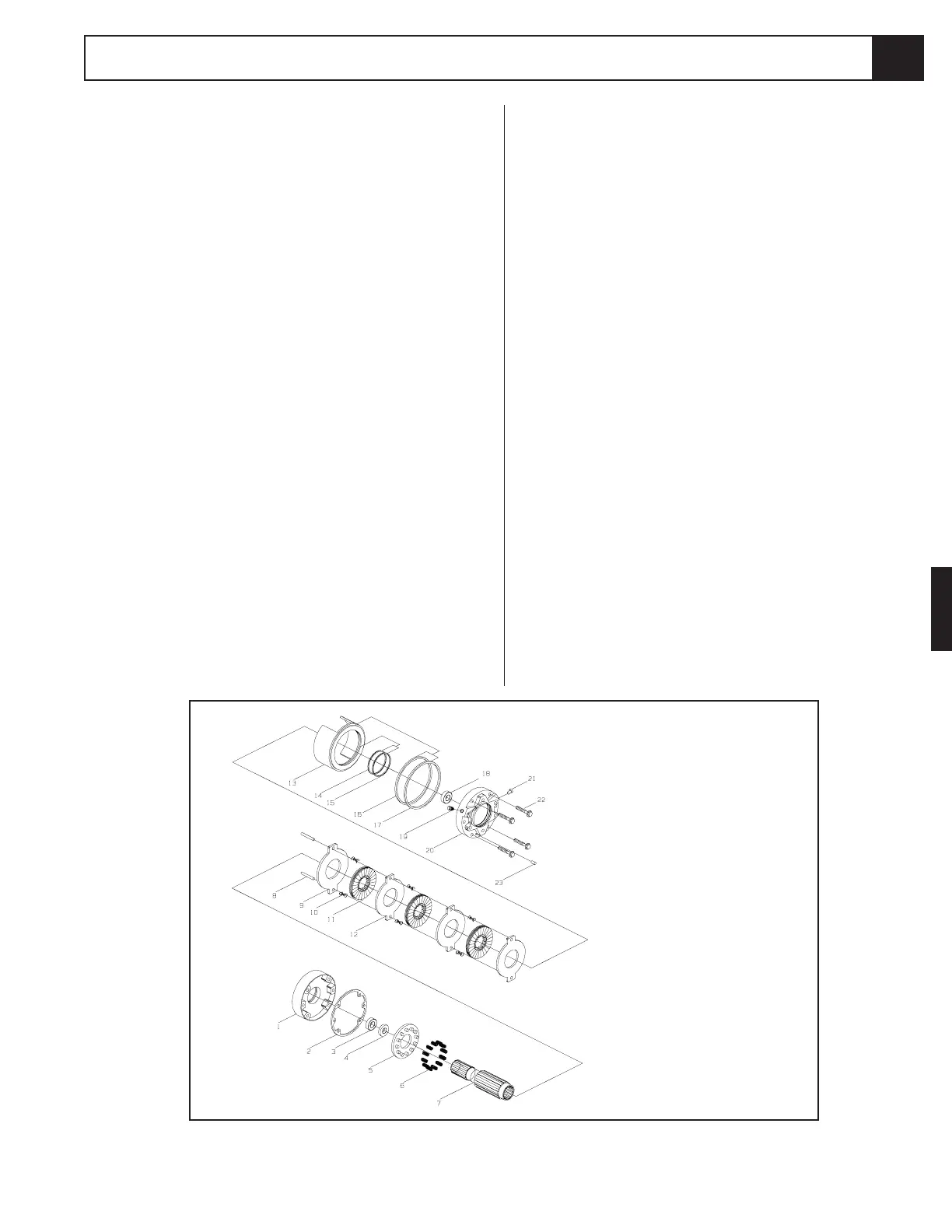

Figure 4-15: Brake Assembly

1. Housing

2. Gasket

3. Ball Bearing

4. Oil Seal

5. Spring Retainer

6. Spring, Compression

7. Shaft

8. Pin, Torque

9. Primary Disk

10. Spring, Compression

11. Rotating Disk.

12. Stationary Disk

13. Piston

14. Backup Ring

15. O-ring

16. Backup Ring

17. O-ring

18. Ball Bearing

19. Plug, Protective

20. Power Plate

21. Bleeder Screw

22. Capscrew

23. Pressure Relief Valve

Installation

1. Install the torque hub to the rear axle. Align the

holes and install the eight capscrews, tighten.

2. Coat the output shaft of the brake with high pressure

molybdenum grease and install brake into torque

hub. Align holes and install the two socket head

through bolts, tighten.

3. Coat the output shaft of the drive motor with high

pressure molybdenum grease and install into brake.

Align holes and install the four capscrews, tighten.

4. Reinstall the hose assemblies to the drive motor and

brake.

5. Reinstall the wheel and wheel nuts onto the torque

hub. Torque the wheel nuts to 90 ft. lbs. (122 N-m).

6. Remove the jack stands used to block the wheels.

Lower the jack and remove.

7. Operate the drive system to check for leaks. If the

brake was serviced, bleed out the air using the bleed

valve located on the brake housing.

Seal Replacement, Brake (Figure 4-15)

1. With shaft protrusion downward remove the cap-

screws (22) from the brake assembly.

2. Remove the power plate (20) from the housing (1).

3. Remove the gasket (2), discard.

4. Remove the piston (13) from the power plate (20)

by introducing low pressure air (15 psi) into the

hydraulic inlet. Make sure the piston is pointed

away from anyone.

5. Remove o-rings (15 & 17) and backup rings (14 & 16)

from the inner and outer diameter grooves of the

piston, discard.

6. Clean the piston (13) and power plate (20) assem-

blies with solvent. Inspect the sealing surfaces of the

piston (13) and power plate (20). Inspect the seal

grooves in the piston. Replace these parts if they are

damaged or scratched deeply. Lubricate piston

(13), power plate (20), and seals (14, 15, 16, & 17)

with clean hydraulic oil prior to assembly.

7. Install the backup rings (14 & 16) and o-rings (15 & 17)

into the seal grooves in the piston.

8. Install the piston into the power plate using a shop

press. Be careful not to damage the seals during

assembly. Center the cutouts in the piston with the

torque pin holes in the power plate. Press the

piston to a depth no less than flush, but not exceed-

ing 0.120 in. below the surface of the power plate at

the cutouts in the piston. This depth is critical, the

brake will not hold if it is exceeded.

9. Install gasket (2).

10. Install power plate / piston assembly (13 & 20) to

housing (1) using capscrews (22). Tighten sequen-

tially, one turn at a time, to press the two assemblies

together. Torque capscrews 50 to 60 ft.-lbs.

Loading...

Loading...