Section

4-25LX 31/41 Work Platform

Maintenance

4.12

INSTALLATION

NOTE: Before installing the cylinder, check the pins

and bearings for excessive wear. Replace if neces-

sary.

1. Using a suitable lifting device, lower the cylinder

into the elevating assembly from the front. DO

NOT sling the cylinder by the rod end pivot, this

will cause the cylinder to extend when hoisted.

2. Align the pivots and install the pivot pins, lower one

first, then the upper one.

3. Install the retaining bolts into the pivot pins.

4. Install the down valve and cable assembly. Adjust

the cable to stop on the collar of the cable jacket,

before the down valve reaches the full extent of it's

pull. The down valve may leak if the cable is

allowed to pull the spool of the valve beyond it's

limit.

5. Install the hoses.

6. Lift and lower the machine for several cycles to work

out the air. Check for leaks, repair as necessary.

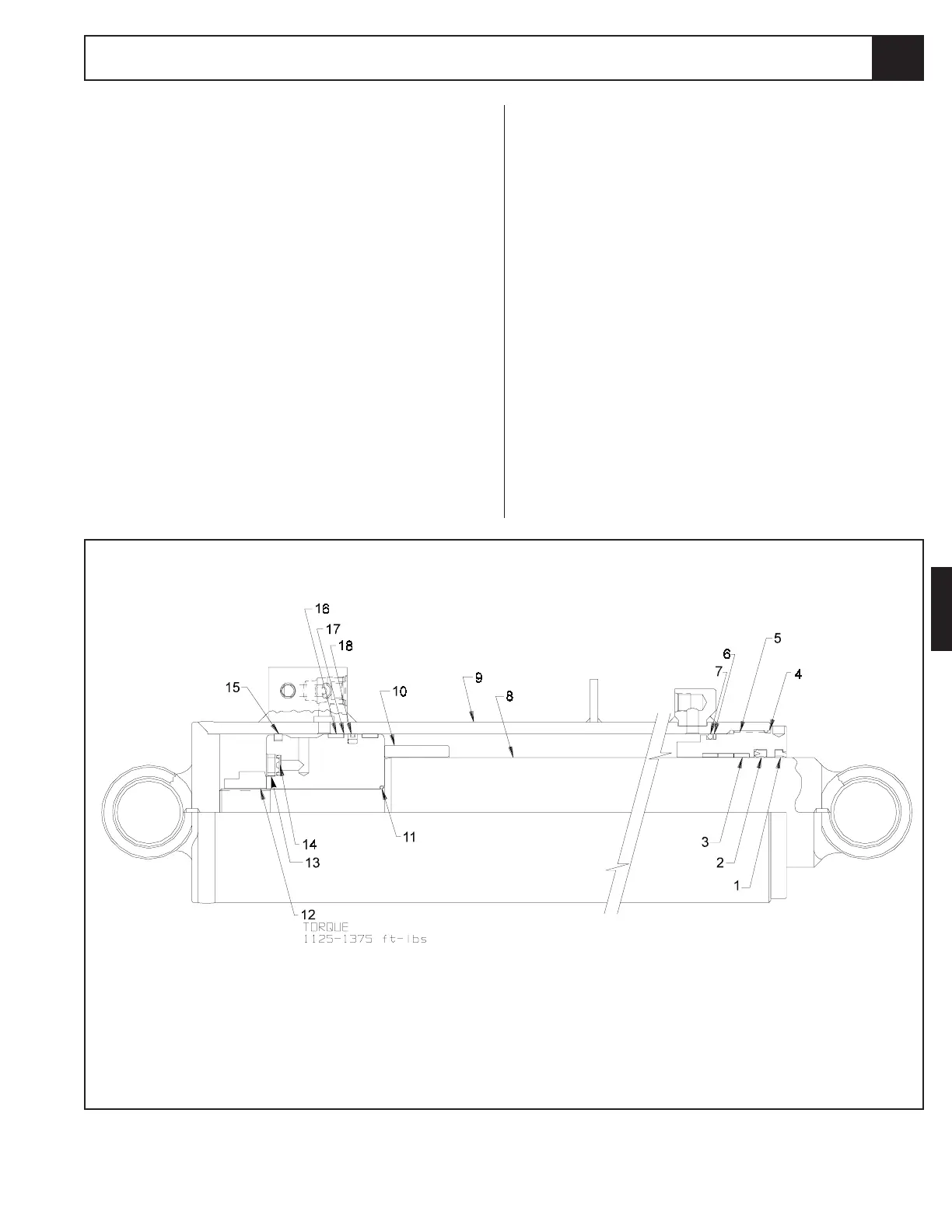

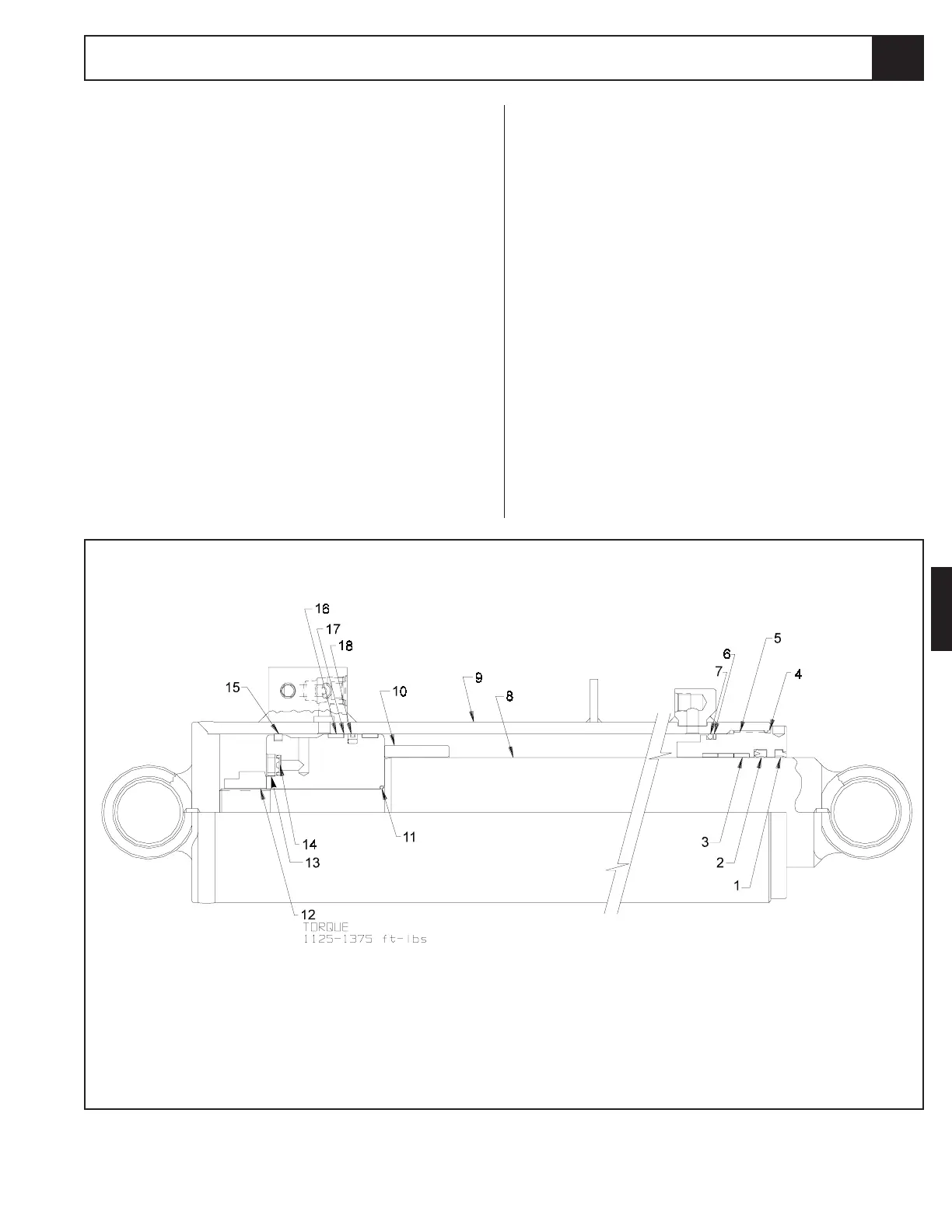

Figure 4-24 Lift Cylinder Cross Section

1. Rod wiper

2. Rod seal

3. Wear ring 3 req'd

4. O-ring

5. Head

6. Backup ring

7. O-ring

8. Rod weldment

9. Tube weldment

10. Spacer

11. O-ring

12. Locknut

13. Bushing

14. Orifice

15. Cast iron ring

16. Wear ring 2 req'd

17. Piston

18. Piston seal

Loading...

Loading...