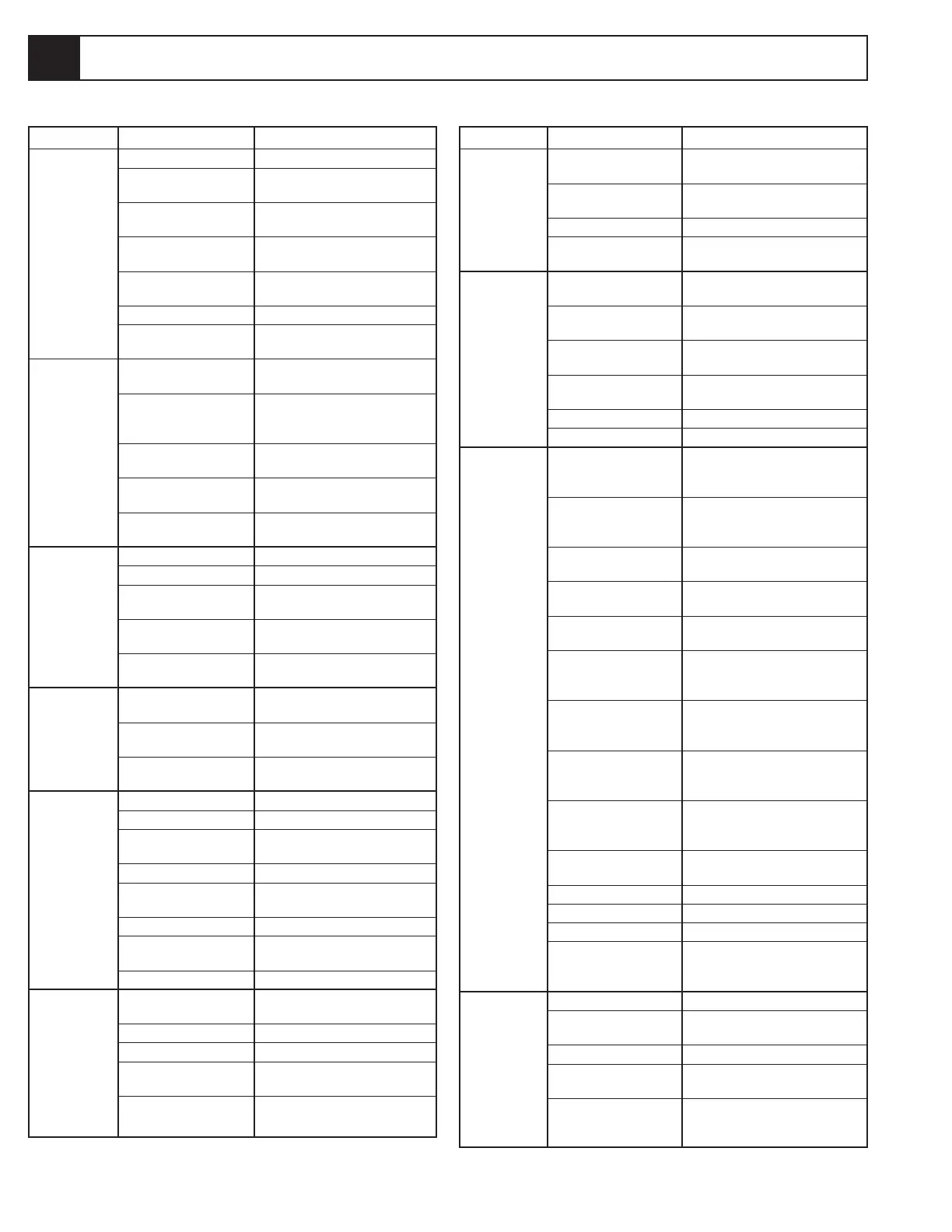

Section

Troubleshooting

5-2 LX 31/41 Work Platform

Table 5-1: Troubleshooting Guide (cont'd.)

PROBLEM PROBABLE CAUSE REMEDY

Engine starts 1. Low fuel level. Fill fuel tank.

then stops. 2. Fuel Filter clogged. Clean or replace the filter

element.

3. Air leaks in Tighten all fuel line connections

the fuel system. and clamps.

4. Water in the fuel. Drain the tank if necessary to

remove all water.

5. Fuel pump Check fuel delivery, replace

defective/damaged. pump if necessary.

6. Clogged air filter. Clean or replace air filter.

7. Key Switch. Switch defective or damaged.

Replace the switch.

All functions 1. Hydraulic Check hydraulic fluid level,

inoperable. Reservoir low. top off as required.

Engine starts. 2. Faulty Hydraulic Check pressure and delivery

Pump. of the Hydraulic Pump.

Replace if required.

3. Damaged Drive Remove pump from engine

Coupling. and check coupling.

4. Proportional Check operation. Replace if

Valve. required.

5. Faulty Proportional Check operation. Adjust or

Controller. replace if required.

Loss of power 1. Clogged Air Filter. Clean or replace the filter.

2. Clogged Fuel Filter. Replace the filter.

3. Incorrect fuel. Drain and refill tank with

proper fuel.

4. Fuel pump Replace the pump.

defective/damaged.

5. Incorrect Fuel Mixture. Follow Idle Speed Adjustment

(Gasoline) procedure, Section 4.14.

Engine stops. 1. Fuel Tank empty. Refill tank and prime system

as required.

2. Water in fuel. Drain fuel system to remove all

water and refill with fresh fuel.

3. Oil Pressure Switch Check Pressure Switch.

inoperative. Replace if faulty.

All Controller 1. Blown fuse. Find short. Replace fuse.

functions 2. Key Switch. Replace switch if inoperative.

inoperative. 3. Faulty Interlock Check Interlock Switch for

Switch. continuity, replace if faulty.

4. Faulty E-Stop Switch. Replace E-Stop Switch if inoperative.

5. Control Cable. Test cable and replace if

damaged.

6. Faulty Controller. Replace Controller if inoperative.

7. Faulty Proportional Replace Proportional Valve if

Valve. inoperative.

8. Faulty Cutout Relay. Replace Cutout Relay if inoperative.

Platform will 1. Platform Observe maximum load rating.

not elevate. overloaded.

2. Out of level. Elevate only on level ground.

3. Lift Relay Faulty. Check / replace lift relay.

4. Lift Valve faulty. Test solenoid and replace

if inoperable.

5. Lift Relief Check and Replace the relief

Valve. valve if necessary.

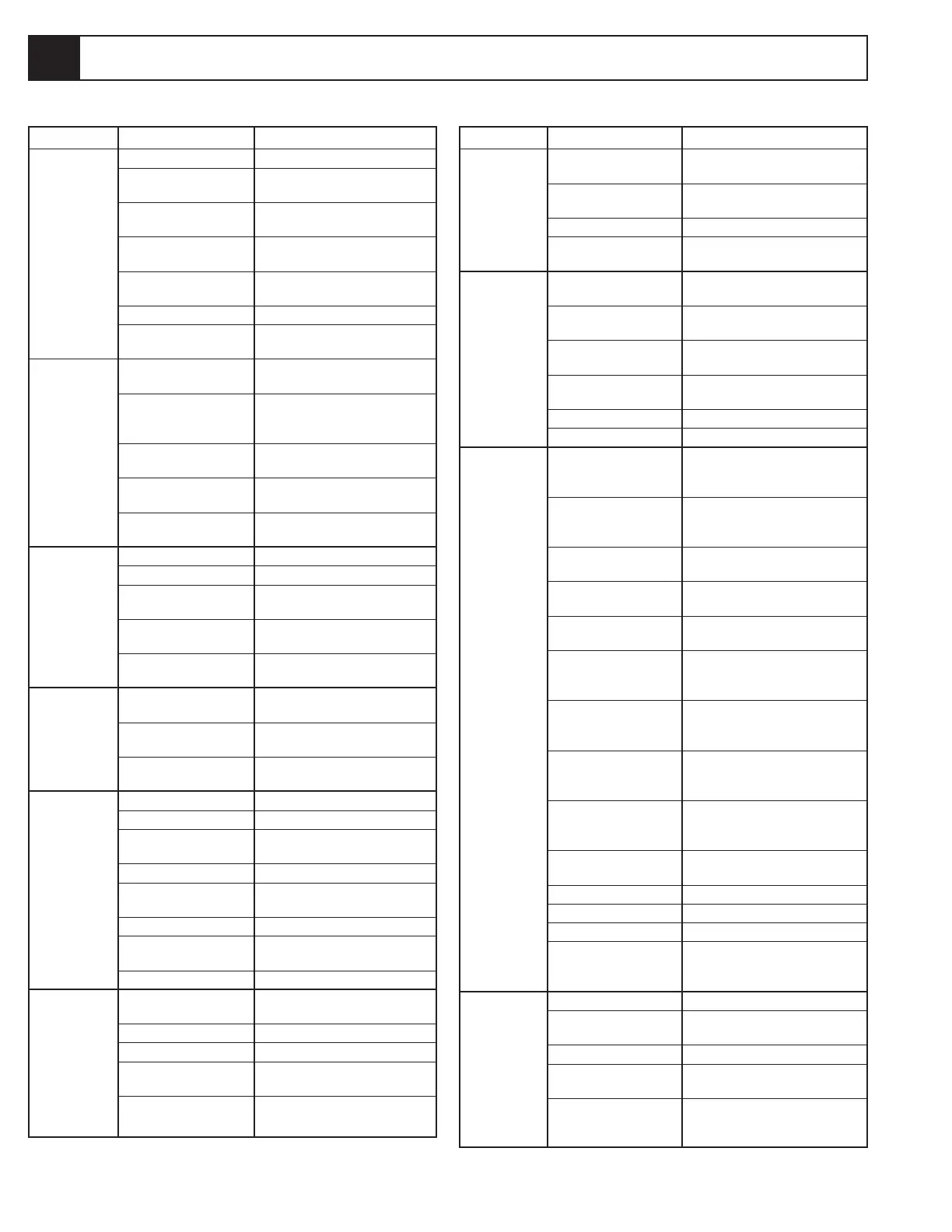

PROBLEM PROBABLE CAUSE REMEDY

Platform will 6. Drive/Lift Switch on Test switch, replace if

not elevate. upper controls. inoperable.

(cont'd) 7. Hydraulic Pump. Check for pressure and delivery.

Repair or replace if inoperative.

8. Proportional Valve. Test and replace if inoperable.

9. Proportional Test controller, replace

Controller. if inoperable.

Unit will not 1. Steering Valve Test coils, replace if inoperative.

steer. Coils (right and left).

2. Open circuit Test cable for continuity, replace

in Control Cable. if defective.

3. Steering Valve. Test valve, replace if not

serviceable.

4. Mechanical Replace damaged parts.

damage.

5. Steering Switch. Replace steering switch.

6. Steering Orifice. Remove and clean orifice.

Unit will not 1. Drive/Lift Switch. Position switch in DRIVE

drive. position. Test switch and

(Platform replace if inoperative.

Lowered) 2. Forward or Test solenoid and replace if

Reverse Solenoid inoperative.

Valve.

3. Control Cable. Test cable and replace if

damaged.

5. Proportional Check controller adjustments,

Controller. replace if inoperable.

6. Main Relief Valve. Test relief valve and replace if

not serviceable.

7. Hydraulic Pump. Test pump pressure and

delivery. Replace if not

serviceable.

8. Hydraulic Test hydraulic pressure at

Motors. drive circuit. If normal, replace

motors.

9. Drive Relay. Check for contact closure when

energized. If contacts do not

close, replace the relay.

10. Lift/Drive Check for continuity across

Relay. contacts, if none replace the

relay.

10. Cutout Relay. If cutout relay is faulty, alarm will

sound. Test and replace cutout relay.

11. Platform Down Switch. Test and replace magnet switch

12. Froward or Reverse Test / replace Forward or Reverse

Relay. Relay.

13. Series / Parallel valve. Trade Series / Parallel valves with

Forward / Reverse Valves. If problem

moves, replace affected valve.

Unit will not 1. Down Limit Switch. Test / replace magnet switch.

drive full 2. Series/Parallel Test solenoid and replace if

speed. Valve solenoids. inoperable.

3. Proportional Controller. Replace controller if not adjustable.

4. Proportional Replace valve if Lift function is

Valve. also affected.

5. Hydraulic Inspect the motors and replace

Motors worn. if not serviceable.

5.1

Loading...

Loading...