C

HAPTER

3. M

AINTENANCE

P

ROCEDURES

3-79

02.9628.0010 CONFIDENTIAL

7-Oct-97

CAUTION

: It is essential that tilt mechanism belt be adjusted correctly.

Overtightening belt can cause high failure rate.

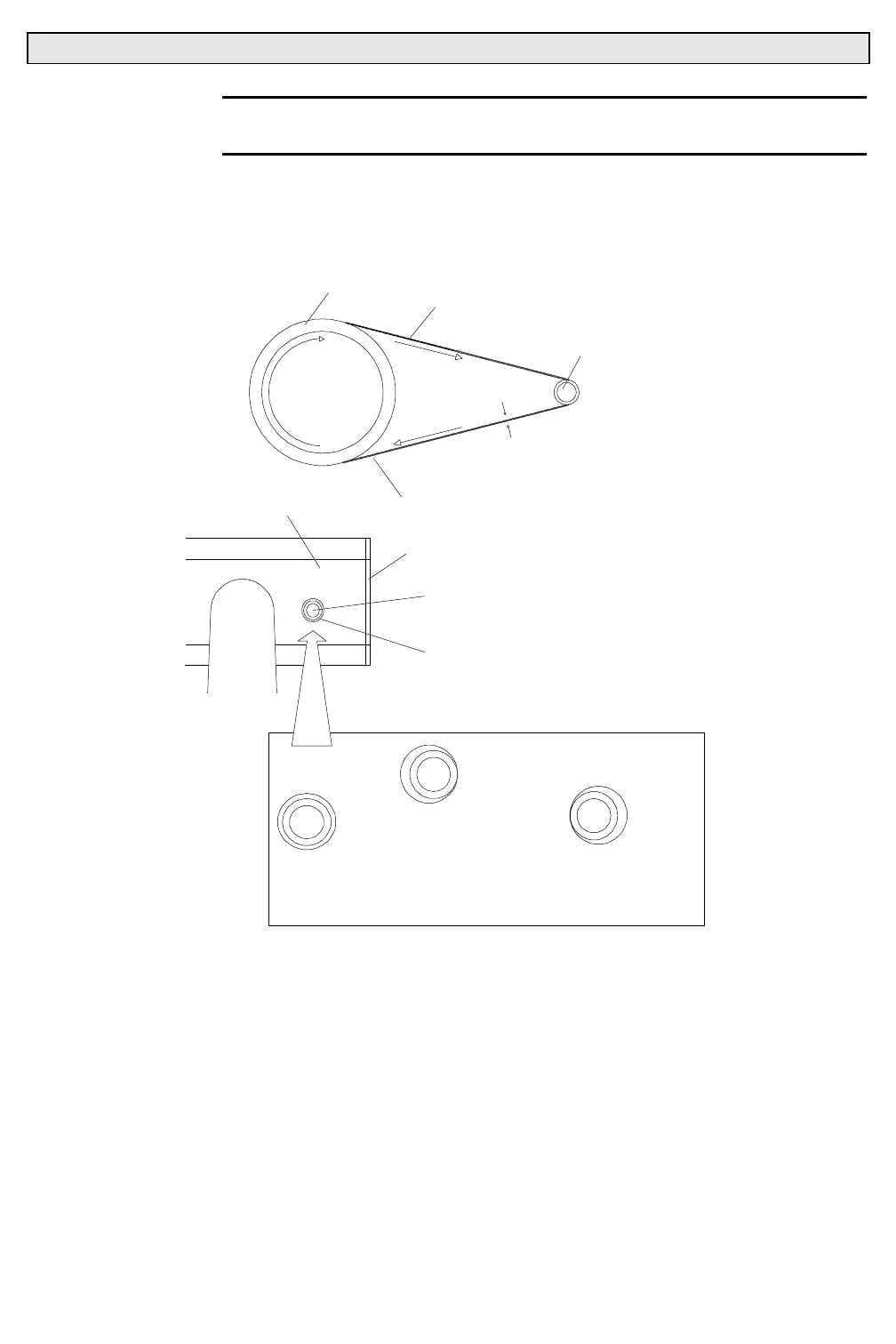

Step 13. Adjust belt tension.

a. Tighten belt adjustment screw and then check tension of

belt (

Figure 3-26

).

FEED SIDE OF BELT

TENSION SIDE OF BELT

PULLEY

DRIVE PULLEY

BELT MUST BE TAUT

(NO DEFLECTIONS)

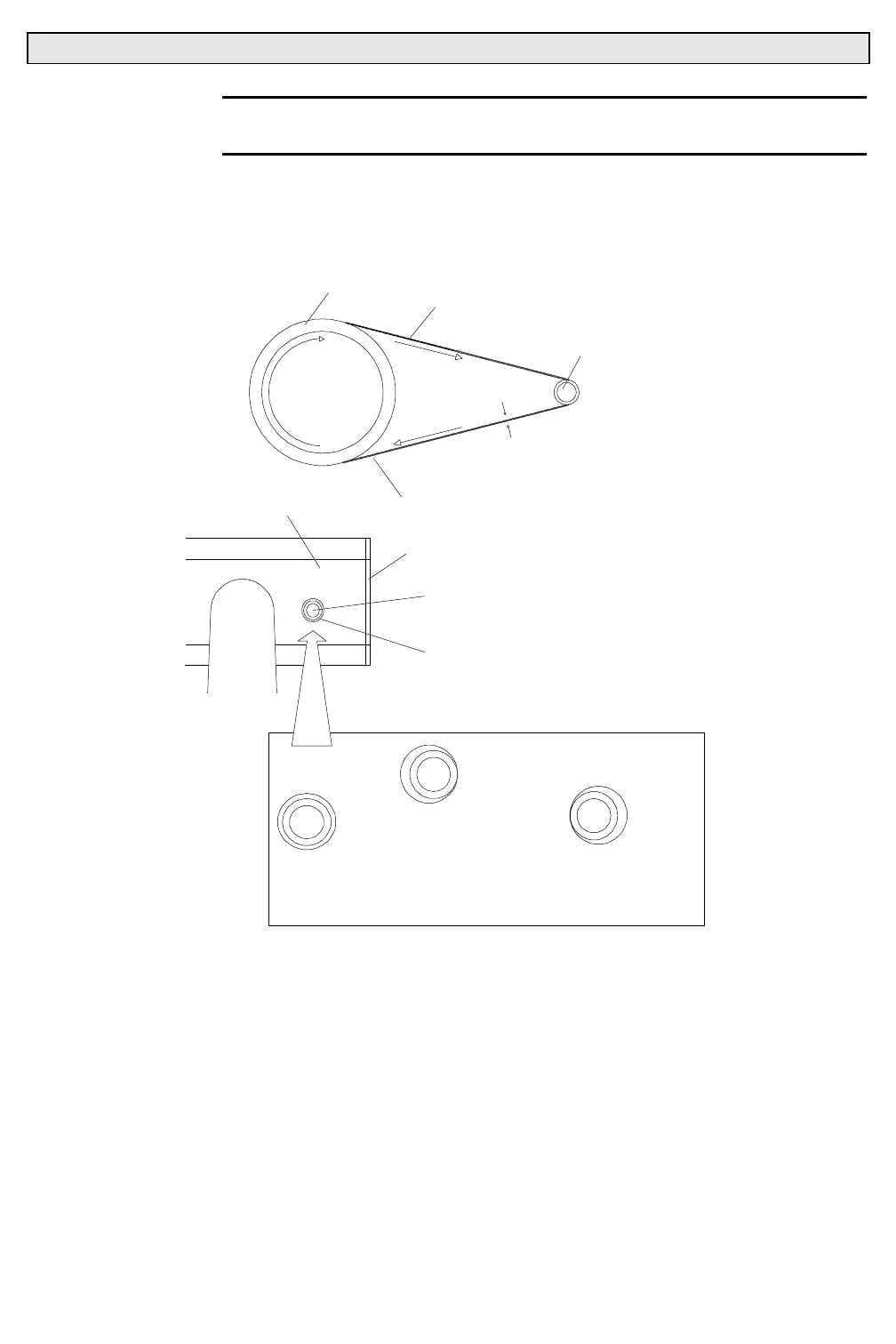

PULLEY SIDE RAIL

REAR COVER

BEARING

HOLE

DRIVEVW

GOOD:

GAP EXISTS BETWEEN

BEARING AND HOLE

TOO TIGHT:

BEARING IS FLUSH

AGAINST HOLE

TOO LOOSE:

BEARING IS FLUSH

AGAINST HOLE

Figure 3-26. Tilt Mechanism Adjustment Screw Setting

b. Turn head so that pulleys rotate back and forth. At same

time, slowly tighten adjustment screw until both tension and

feed sides of belt are taut (no deflections).

Step 14. Complete tilt mechanism replacement by doing Steps 2 thru 11

in reverse.

Loading...

Loading...