44 030624.13

vetus® Electronic engine remote control

8.2 Wiring from the actuator to command stations, engines, gearboxes, trim/flaps, etc (out-

put cables)

Almost every cable is provided with its unique connector, therefore it is easy to identify the cable type, its function and

where to mount it. Each connector has a different polarization, so it is almost impossible to mount a cable in the wrong

position. For the description of all the types of cables, look at chapter 6.

When mounting the electronic engine cable on the actuator: align the polarization keys and insert carefully the M12

connector of the cable on the actuator M12 counterpart. Rotate then the M12 ring until the cable enters completely into

the counterpart. If the cable has been inserted correctly, it must be possible to screw completely by hand the cable with-

out too much efforts (around 6 full rotations). For more info look at chapter 6.

There are basically 4 types of actuators classified on the type of interface (mechanic or electronic) and on the type of

connector placed on the actuator itself (with or without neutral relay).

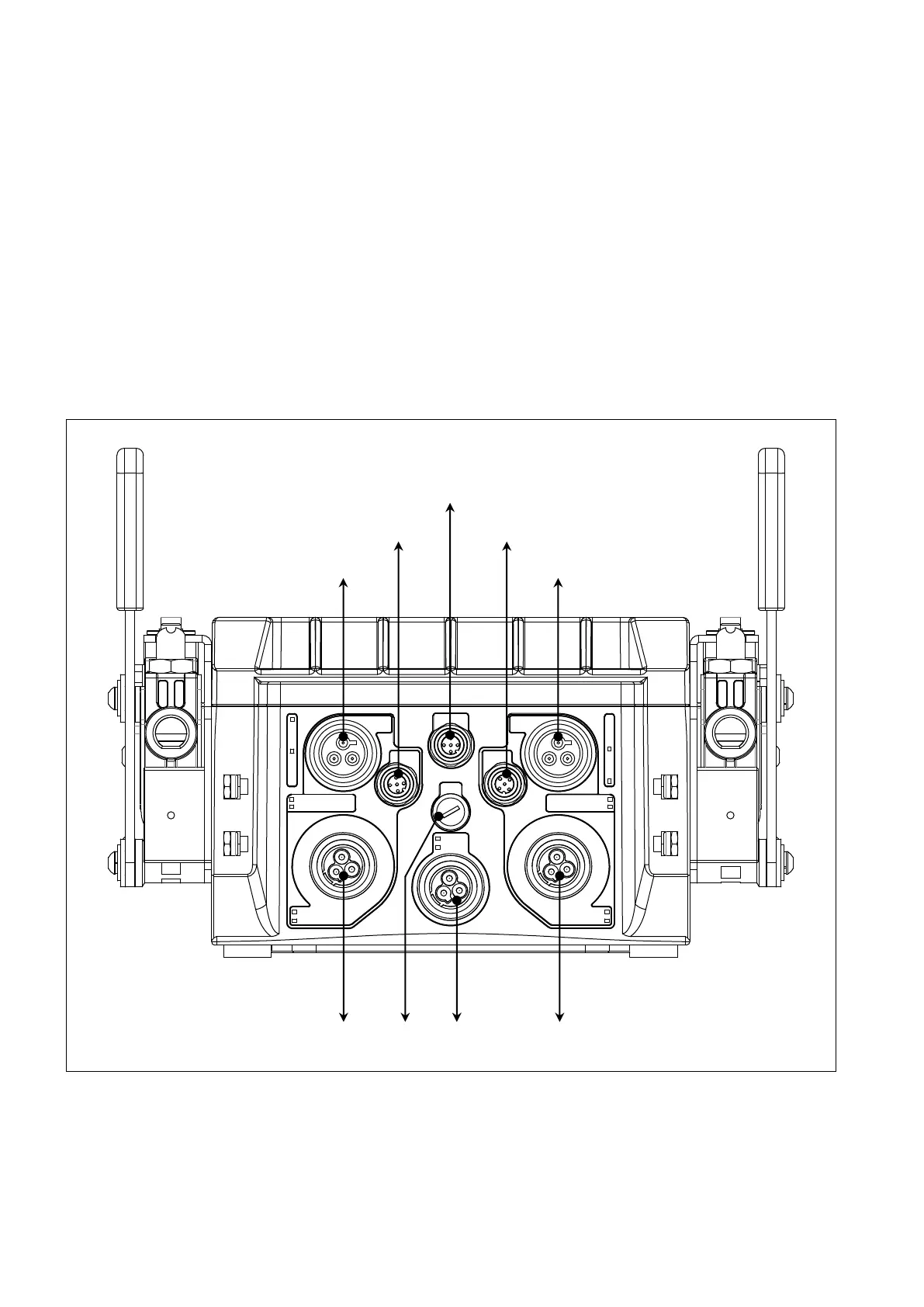

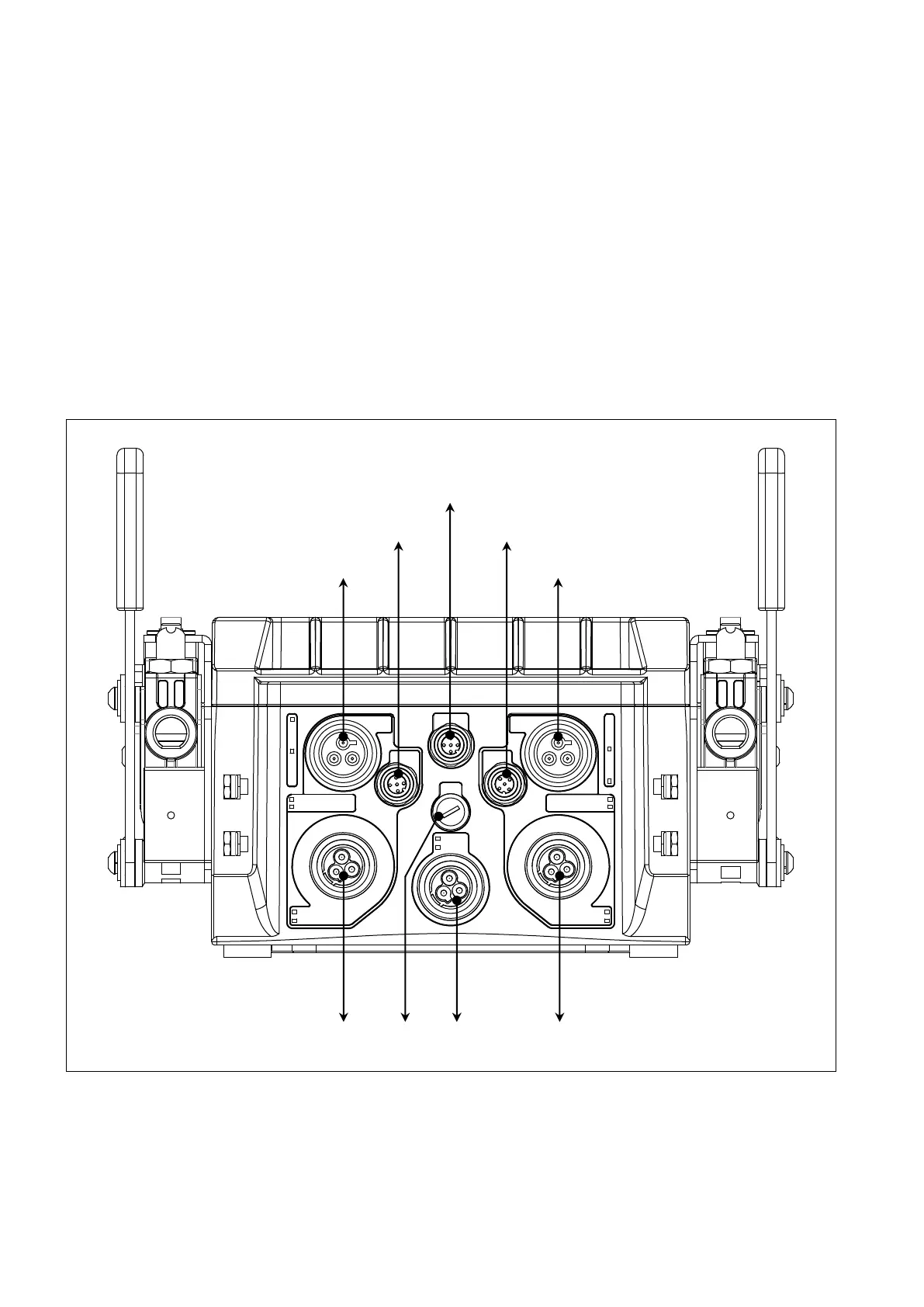

8.2.1 Actuator with mechanical interface without neutral relay

For better comprehension are depicted only the electrical connections and not the mechanical linkages. This actuator is

available in versions with neutral relay, with or without trim and it is suitable for the following applications:

• mechanical engine and mechanical gearbox (only 1 propulsion group per actuator)

• mechanical engine and solenoid driven gearbox (2 propulsion groups per actuator)

• electronic engine and mechanical gearbox (2 propulsion groups per actuator)

ThrottleGear

ThrottleGear

+12 V

+24 V

Trim

Flap

Trim

Flap

Gear

Neutral switch

Gear

Neutral switch

Mech left engine

Ein left engine

Mech left engine

Ein left engine

Canbus

Throttle Throttle

Left gearbox

Left engine - Trim/Flap

Left engine - Throttle

CANBus to the comman station

Left engine - Throttle

Right engine - Trim/Flap

Right gearboxFuse Supply

Loading...

Loading...