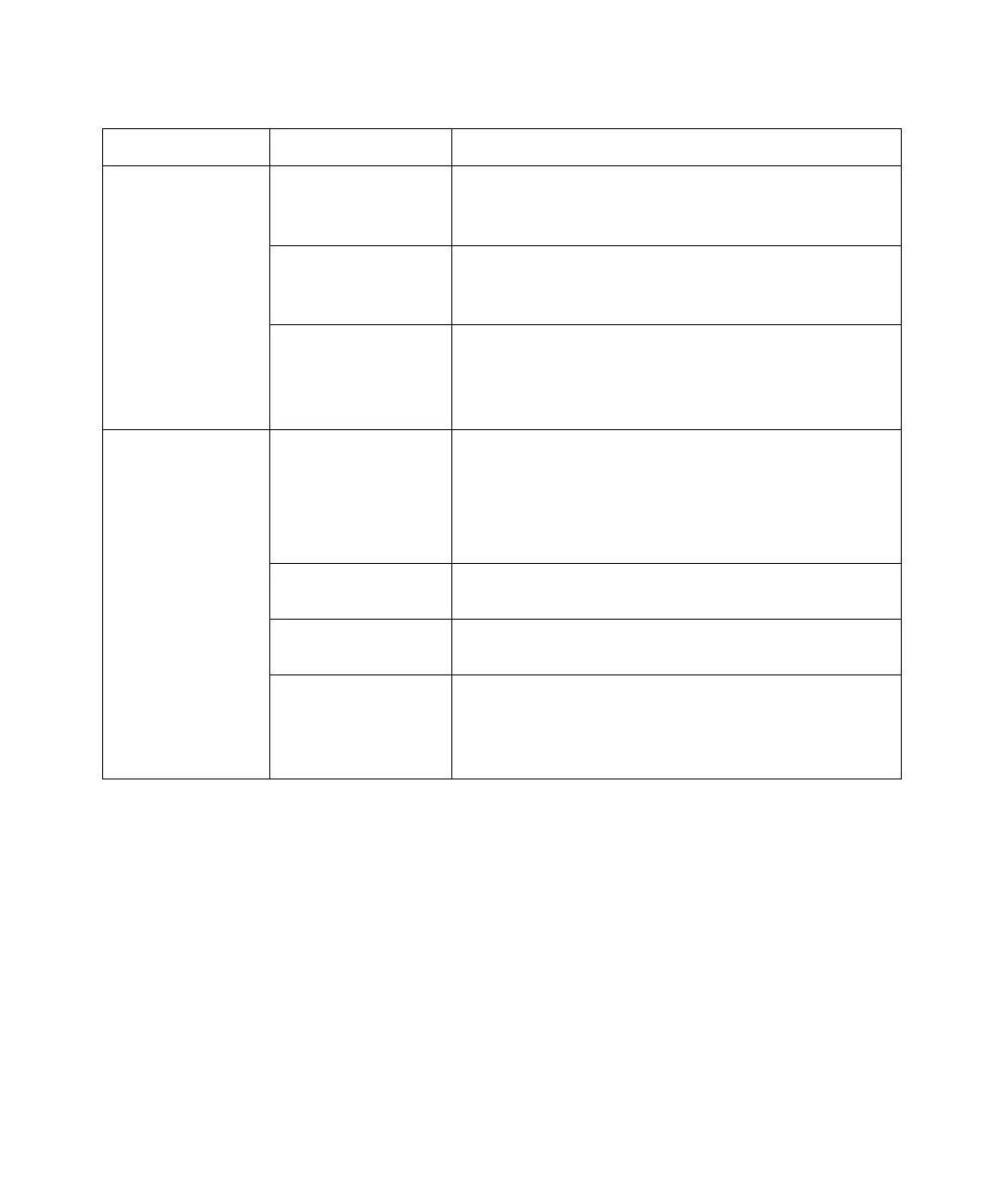

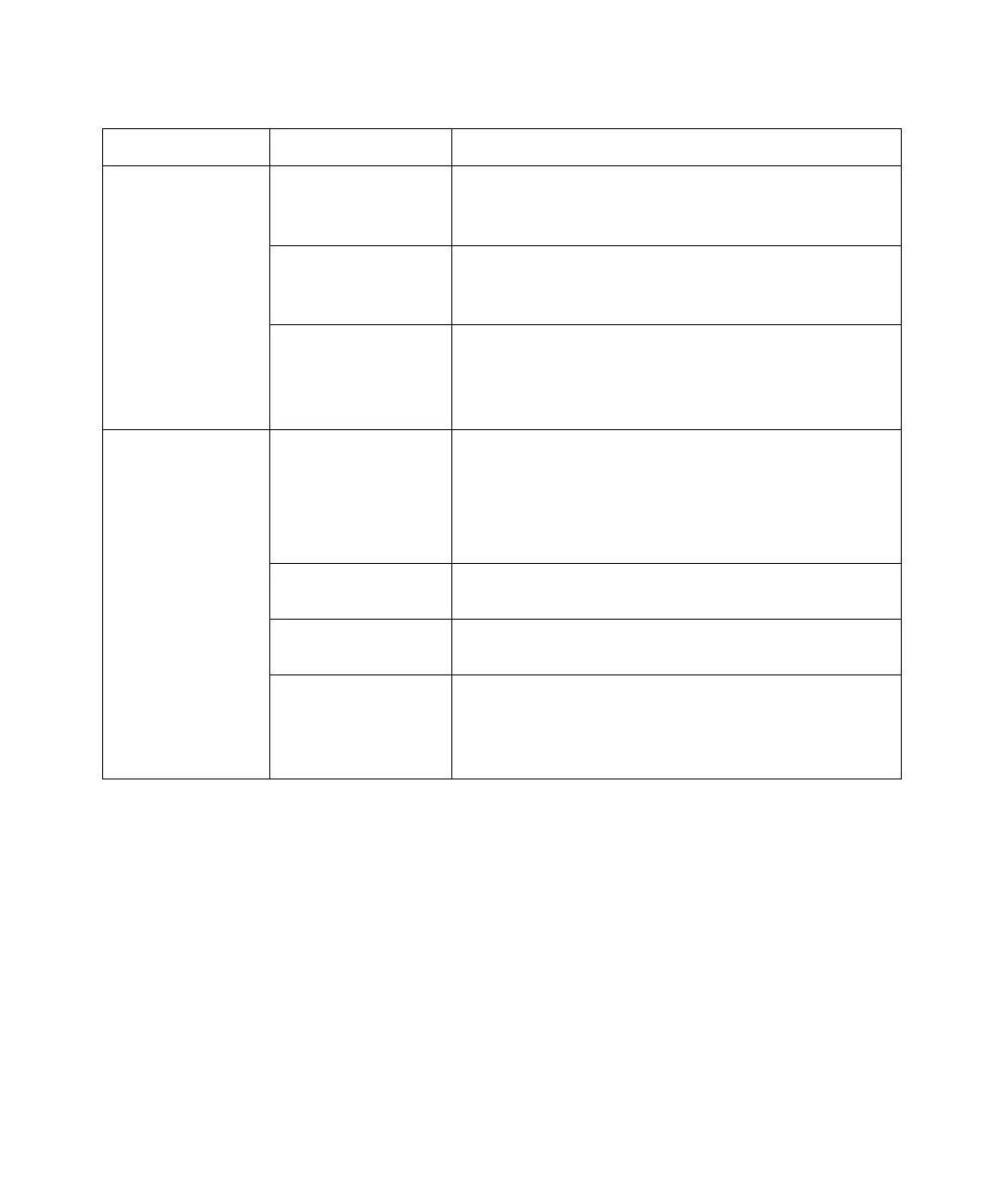

122 Troubleshooting

Leak from pump

head (continued)

Loose pump head Tighten the two pump head screw(s). Ensure both

screws are tightened equally to prevent seal wear. Do

not overtighten.

Loose compression

screw(s) on the

pump head

Tighten the loose compression screw(s) with a

5/16-inch open-end wrench.

Loose inlet or outlet

check valve

Tighten the loose check valve(s). Do not overtighten.

Verify fittings and ferrules for under/overtightening

and wear. Replace if necessary. Refer to Section 2.1,

Selecting and Installing Fittings.

Erratic flow

rate/pump

pulsations

Mobile phase

improperly

degassed or sparged

Degas or sparge the eluent(s) and reequilibrate the

system (see the Waters 600E Multisolvent Delivery

System User’s Guide, Chapter 3).

Limit the amount of helium sparging to avoid

depleting volatile mobile phase components.

Pump not primed Prime the pump (see the Waters 600E Multisolvent

Delivery System User’s Guide, Chapter 3).

Reservoir low or out

of eluent

Check eluent level in reservoirs. Refill as necessary,

and degas/helium-sparge.

Air bubble in pump

head

Prime pump to remove bubble (see the Waters 600E

Multisolvent Delivery System User’s Guide,

Chapter 3). Ensure there are no air bubbles in the

eluent inlet lines. Degas or helium-sparge eluents.

Table 6-1 600E System Troubleshooting (Continued)

Symptom Possible Cause Corrective Action

Loading...

Loading...