66 Maintenance Procedures

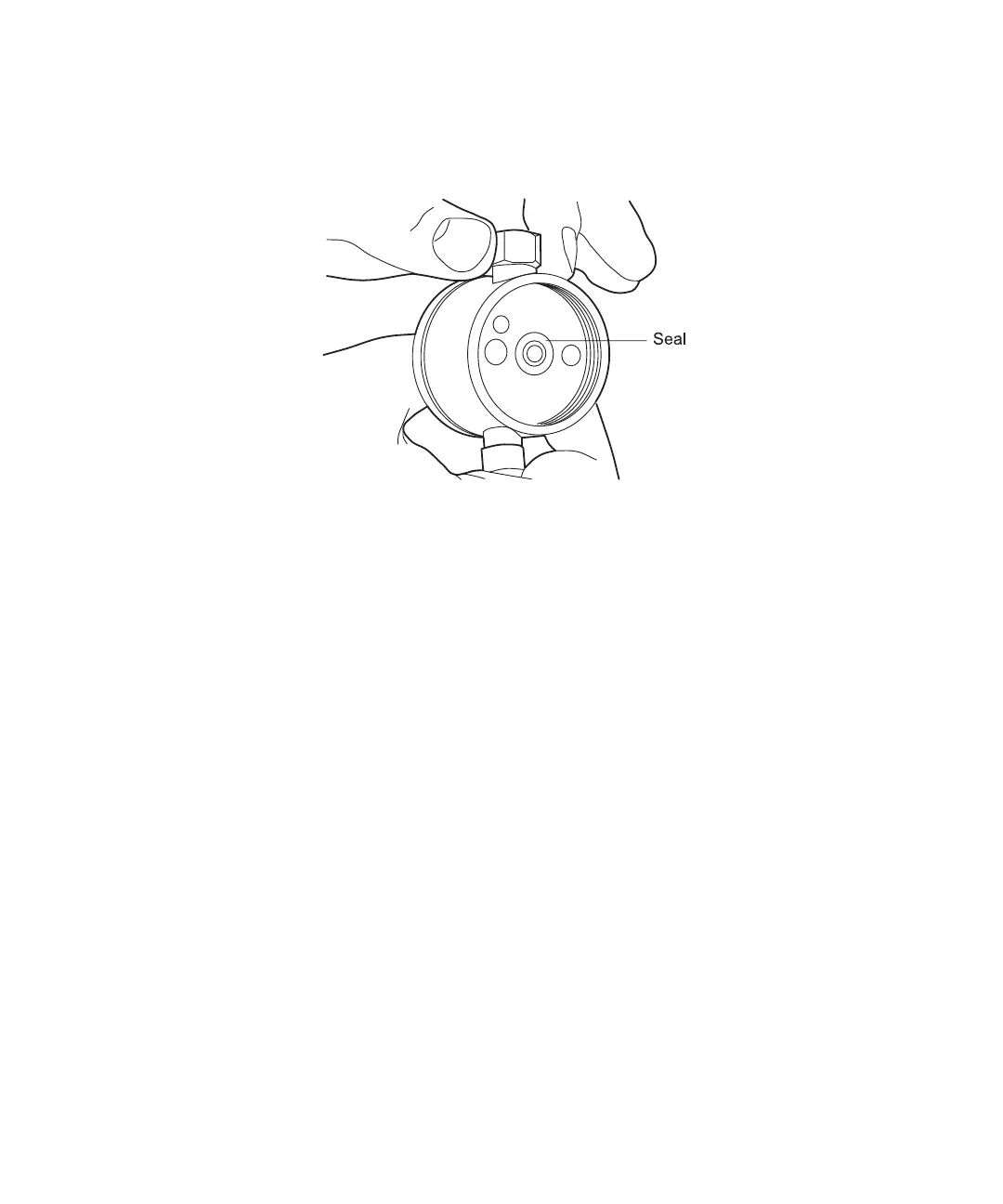

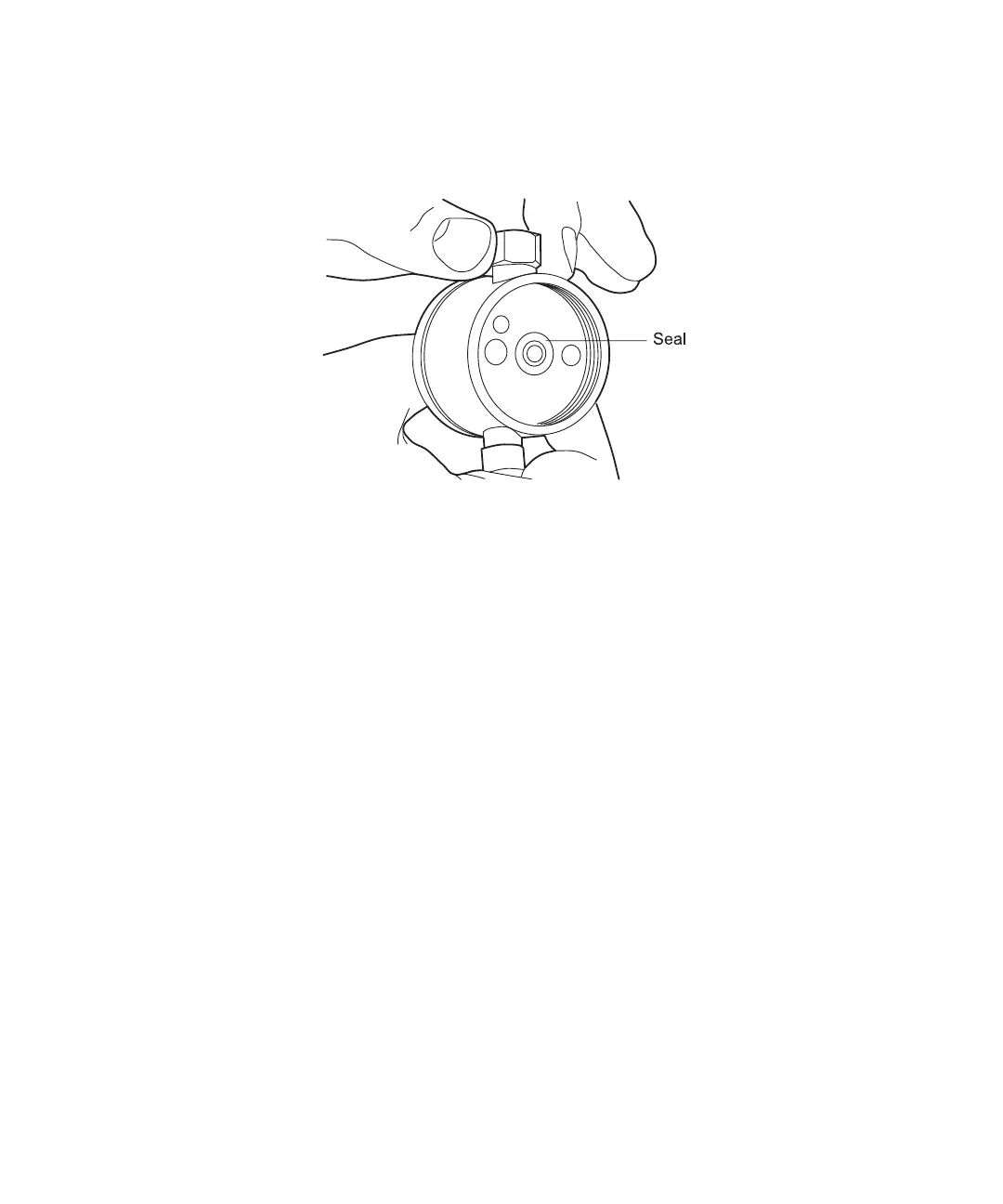

3. Using the seal insertion tool stand tip, pry the seal out of the pump head

(Figure 4-7). The stand tip holds the plunger seal for correct alignment in the pump

head.

Figure 4-7 Plunger Seal Orientation

4. Place the new plunger seal (wetted with methanol) on the seat (wetted with

methanol) for the analytical (100 µL) heads. Insert the plunger seal into the pump

head assembly. For 225 µL heads, insert the seal with the solid side facing out.

5. Use the stand tip to firmly seat the seal in the pump head.

6. Slide the pump head assembly into position over the plunger and replace the two

pump head mounting bolts. Tighten the bolts evenly by alternately tightening one

then the other by half turns.

7. Turn on the pump and set flow rate to 0.3 mL/min. The indicator rod (see

Figure 4-5) should move freely.

8. Set flow to 0 mL/min. Reconnect the eluent lines, reposition the eluent lines in the

reservoir, and prime the pump. Check for leaks. If there is a leak, verify pump head

and plunger seal installation.

Note: For priming information, see the Waters 600E Multisolvent Delivery System

User’s Guide, Chapter 3, Preparing Your System for Operation.

4.2.5 Cleaning and Replacing the Pump Plunger

This section describes accessing the pump plunger to:

• Clean the plunger

• Replace the plunger if there is excessive wear

Loading...

Loading...