10 Making Fluidic Connections to the 600E Pump

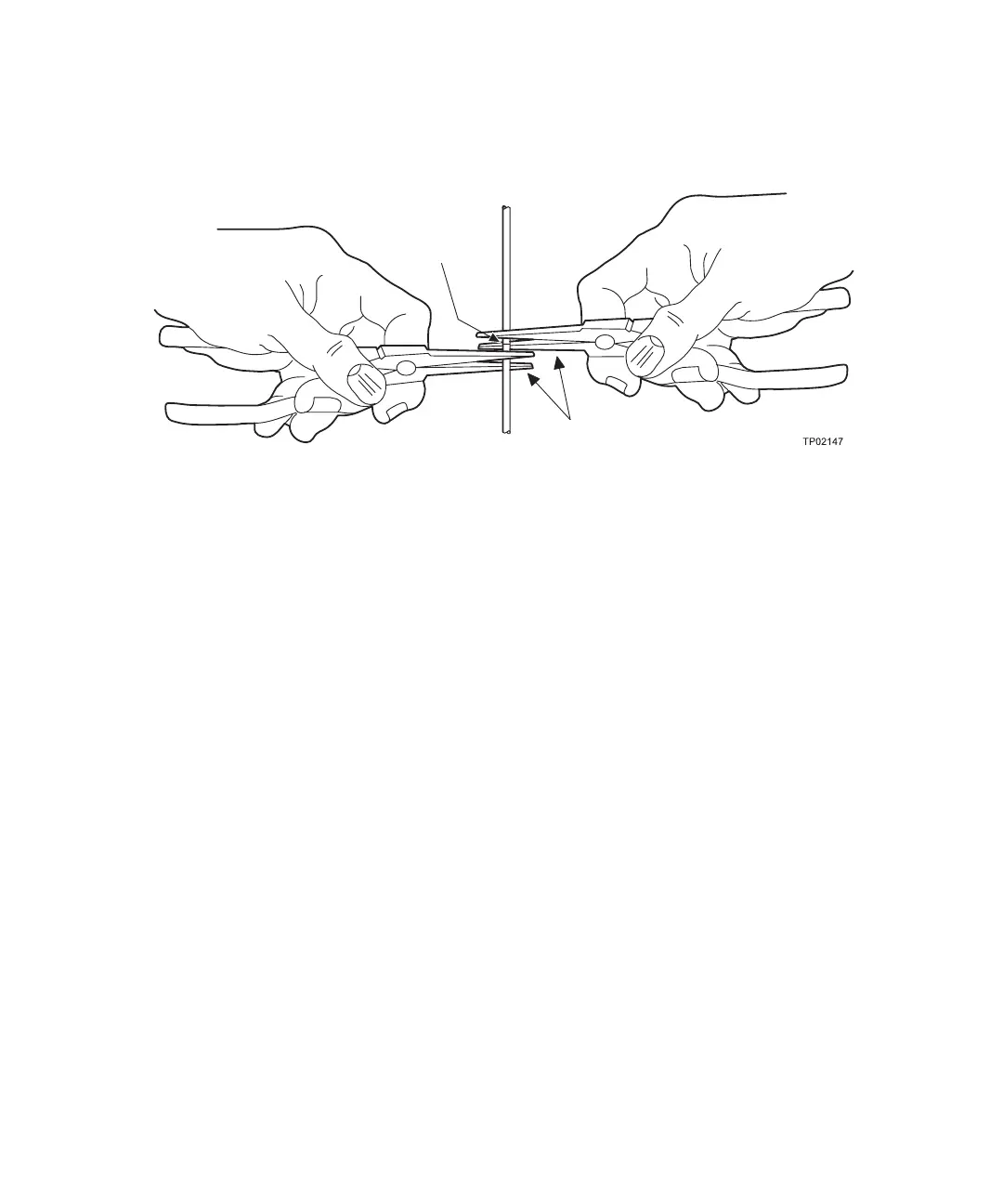

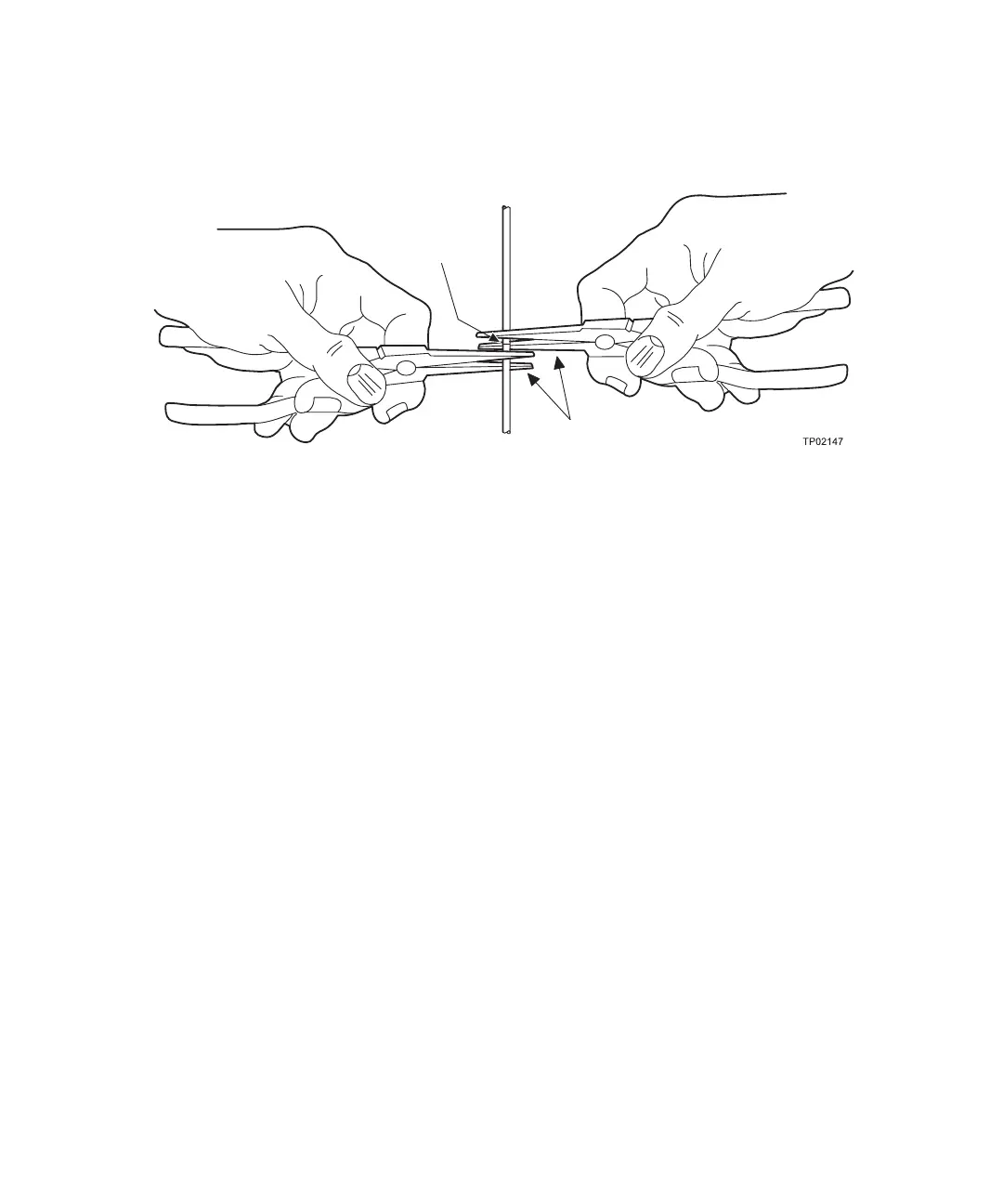

3. Grip the cut tubing with two pairs of smooth-jawed pliers, one on each side of the

score (Figure 2-3). Gently bend the tubing back and forth until it snaps. This leaves

the tubing bore open with a minimum of burrs.

Figure 2-3 Breaking the Stainless Steel Tubing

Deburring Tubing

4. Inspect the cut for burrs or scratches and for perpendicularity. The tubing must be

completely open, without debris or burrs in the hole. If necessary, debur the hole

with a very fine file or deburring tool.

Note: The tubing end must be smooth, fully open, and without burrs to allow proper

seating in the compression fitting and to prevent particles from blocking the tubing.

5. Prior to connection, flush the tubing with solvent to remove any remaining particle.

6. Attach the individual ferrules, compression fittings, and nuts as described below and

in the column or instrument operator’s manual.

2.1.2 Installing Connectors and Fittings

This section includes procedures for installing different types of connectors and fittings on

tubing.

This section covers:

• Connector components

• Assembling a standard ferrule connector

• Assembling a reverse ferrule connector

• Replacing ferrules

Pliers

Loading...

Loading...