Selecting and Installing Fittings 11

Connector Components

Each tubing connector is composed of at least two parts:

•Ferrule

• Compression screw

The ferrule is the component that seals a junction. When pressure is applied to a ferrule,

the ferrule forms a seal against the junction surface by tightening the compression screw.

The connectors supplied with your 600E system are standard ferrule connectors used with

stainless steel tubing.

Note: Use of other-than-factory-installed connectors may cause problems. Connectors

differ due to ferrule shape and fitting bodies (lengths and threads). For guidance when

using nonstandard connectors, contact your local Waters representative.

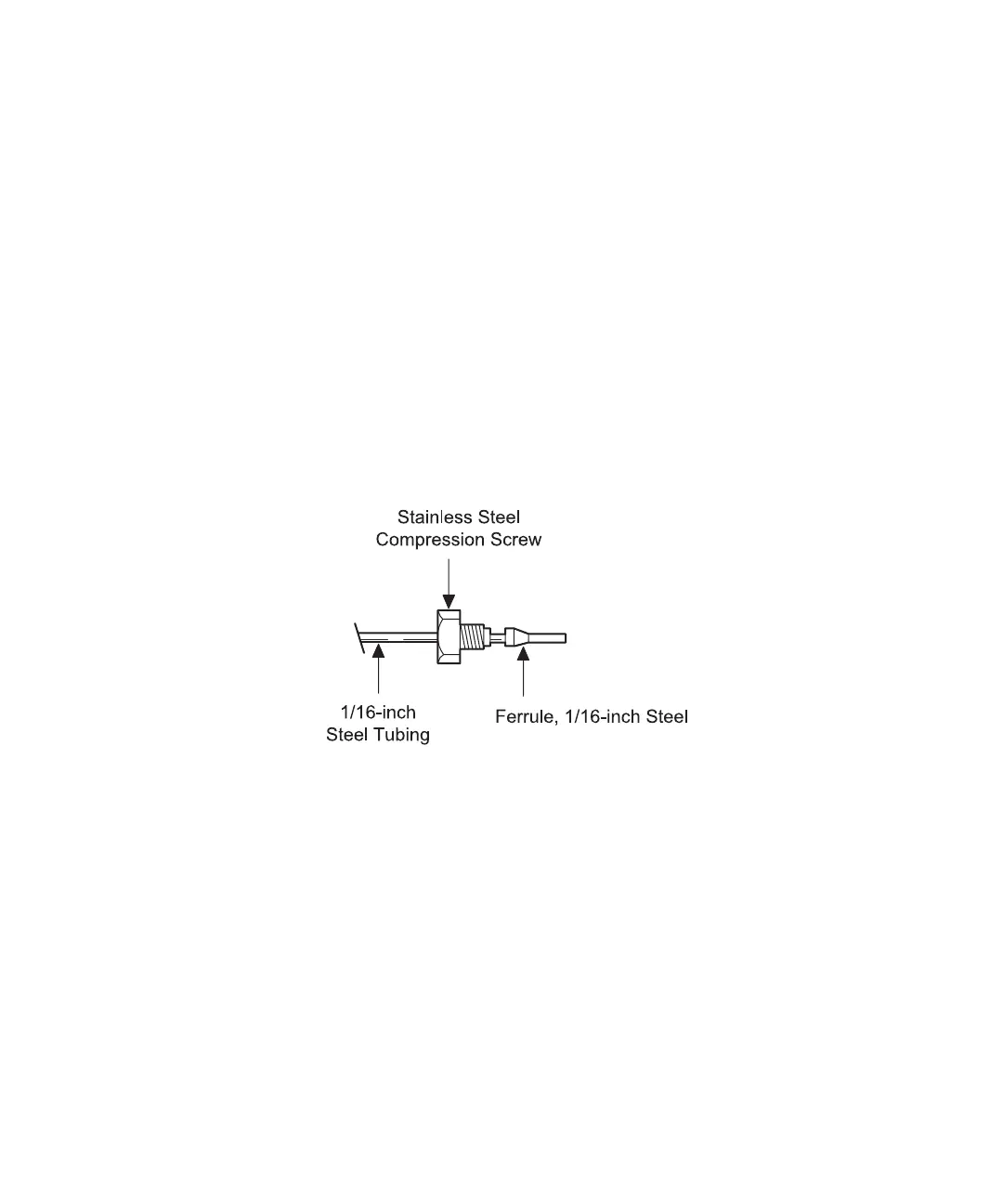

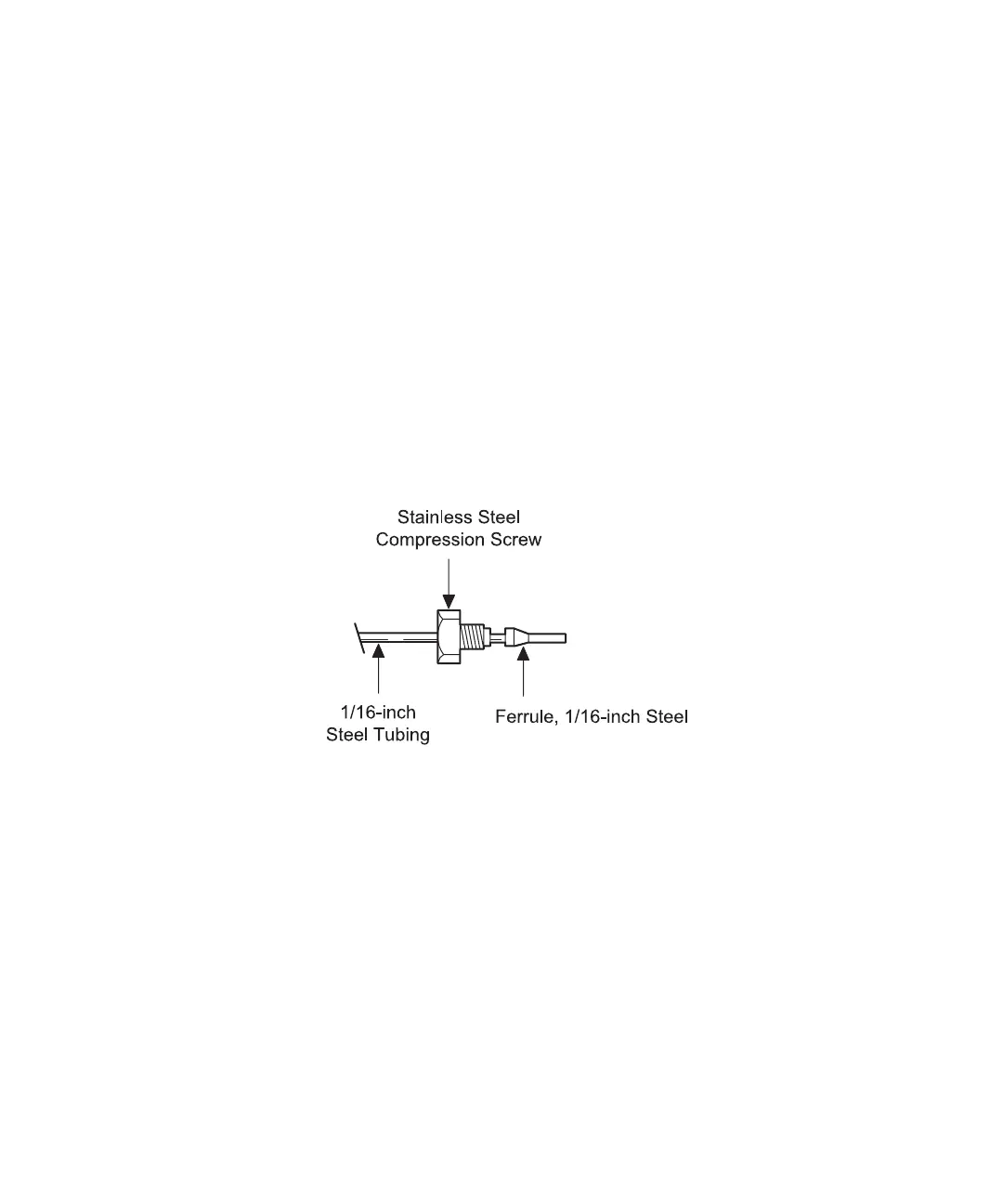

Figure 2-4 shows how to use the connectors listed above.

Figure 2-4 Compression Screw, Ferrule, and Tubing

Assembling a Standard Ferrule Connector

1. Slide the compression screw onto the tubing end (see Figure 2-4). Slide the ferrule

onto the tubing with the broad end of the taper toward the screw.

2. Push the tubing all the way into the fitting body until the tubing bottoms out. The

fitting body can be a stainless steel union, a column end, or any part of the system

that has a female receptacle.

3. While you hold the tubing securely in place (bottomed out), finger-tighten the

compression screw.

Loading...

Loading...