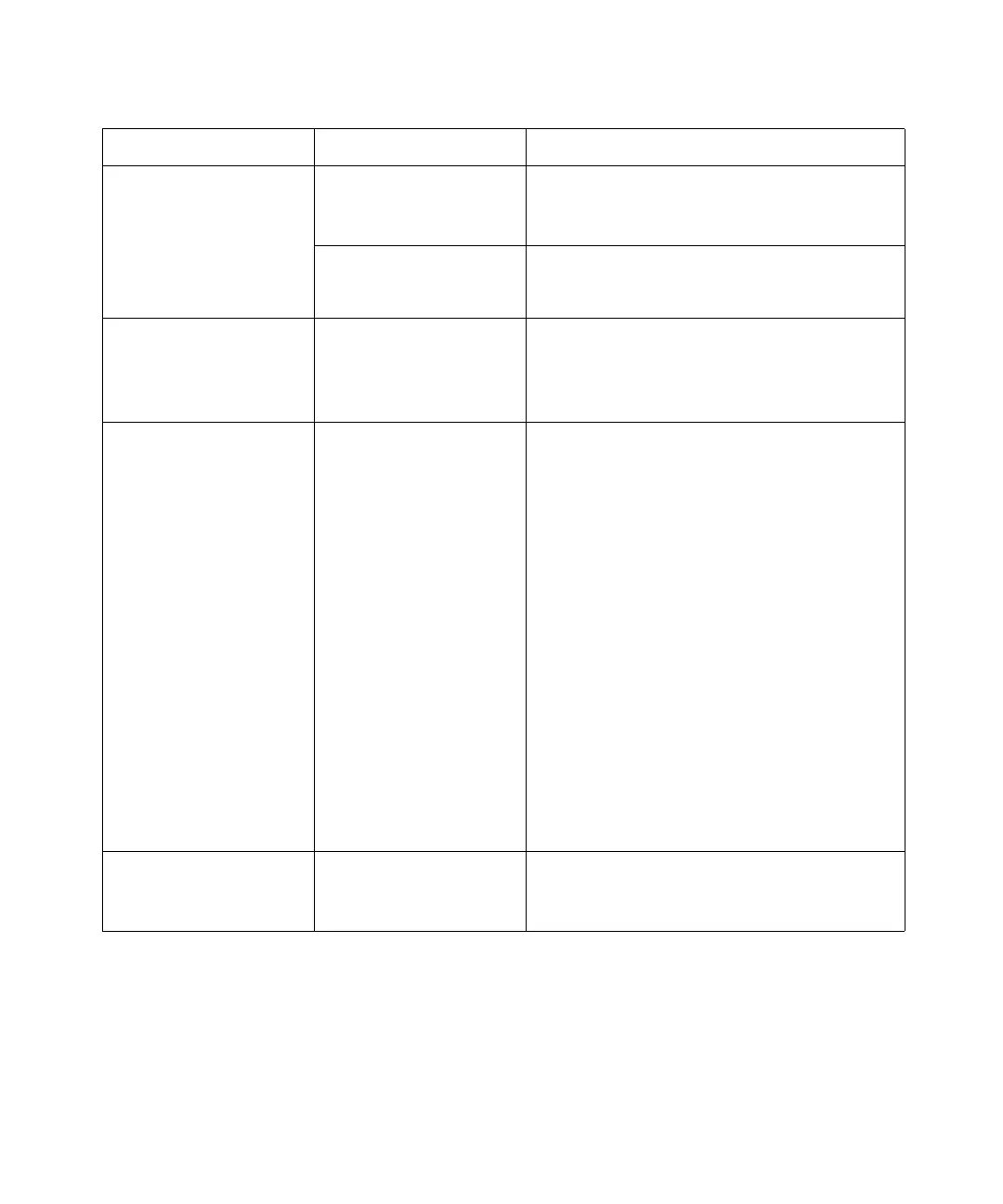

Troubleshooting the Rheodyne 7725i Manual Injector 125

Rotor seal leakage

(liquid dripping

between stator and

stator ring, or from

needle port or vent

tube)

Pressure adjusting

screw loose

Tighten pressure adjusting screw. Refer to

Section 4.4.4, Tightening the Pressure

Adjusting Screw.

Scratches on rotor seal Replace rotor seal. Refer to Section 4.4.3,

Rotor Seal Leakage.

Needle seal leakage Syringe needle OD

smaller than needle

seal, reducing sample

loading accuracy

Try another syringe needle. Gently push on

plastic needle guide to deform Teflon sleeve

to provide a better needle fit. See

Section 4.4.1, Tightening the Needle Seal.

Plugged valve passages

or vent lines

Unfiltered eluent or

sample, or buffer solu-

tions crystallized in

vent lines

Remove the stator and clean the passages

with a wire of 0.005-inch maximum

diameter.

If the valve passage remains plugged,

disconnect the tubing at the vent valve

outlet. If this clears the passage, replace the

tubing. If the passage remains blocked,

disconnect the compression screw at the

vent valve inlet. If this reduces the pressure,

rebuild the vent valve (see the documenta-

tion included with the 7725i injector.

Ensure eluent and sample are properly

filtered to prevent additional precipitation.

Flush the flow passages and vent lines with

water after use of salt solutions. Salt solu-

tions should not sit stagnant in the valve

overnight or for long periods of time.

Gradient does not start Position sensing switch

is not sending the inject

signal to controller

Replace the position sensing switch as

described in Section 4.4.2, Replacing the

Position Sensing Switch.

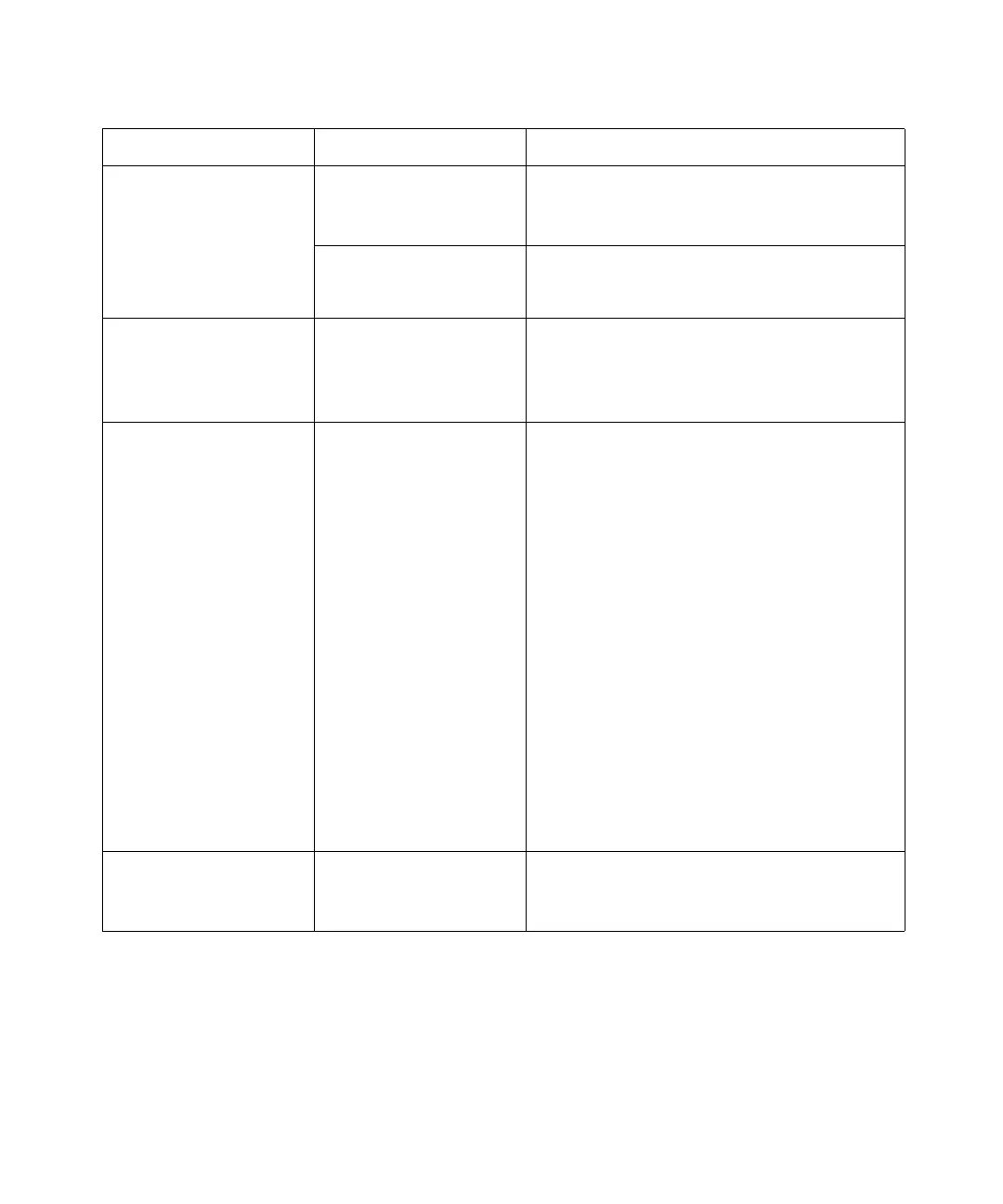

Table 6-2 Rheodyne 7725i Injector Troubleshooting (Continued)

Symptom Possible Cause Corrective Action

Loading...

Loading...