3-3

Phaser 3635MFP

IQ1

Image Quality

Draft 4

IQ1 Image Quality Entry RAP

Use this RAP to determine the source of an image quality problem.

Initial Actions

• Check the condition of the paper. Do not use incorrectly cut paper, damp paper, paper

with rough edges, badly drilled paper, paper with wrapper wax or glue. Paper and media

should be stored flat, enclosed in wrappers, in a cool dry environment.

• Check that the paper is within specifications. Refer to GP 9 Paper and Media Specifica-

tions.

• Check that paper tray guides are set to the correct paper size.

• Check the document guides on the DADF.

• Check the original documents for defects.

• Ensure that the image adjustment mode selections are those used by the customer.

• Check that the machine fans are working, go to the OF3 Air Systems RAP.

Procedure

If necessary, refer to IQ1 Internal Test Patterns for:

• A description of image quality defects.

• The optimum test pattern to be used to diagnose the defect.

• An example of all internal test patterns.

If possible, use the customer job to recreate the image quality problem.

Enter dC606. Select a suitable test pattern. Select the Features, 1 or 2 sided and paper size.

Press Start Test. Go to the relevant RAP:

• IQ2 Blank Copies RAP

• IQ3 Black Copies or Prints RAP.

• IQ4 Blurred Image From the Scanner RAP

• IQ5 Vertical Black Lines or Bands RAP

• IQ6 Vertical White Lines RAP

• IQ7 Light Image RAP

• IQ8 Dark Image RAP

• IQ9 Background RAP

• IQ10 Ghost Images RAP

• IQ11 Stains on Back of Paper RAP

• IQ12 Poor Fusing RAP

• IQ13 Partial Blank Image (Not Periodic) RAP

• IQ14 Partial Blank Image (Periodic) RAP

• IQ15 Different Image Density (Left and Right) RAP

• IQ16 Horizontal Bands RAP

• IQ17 Periodic Printing Defects Check RAP

• IQ18 DADF Lead Edge Offset RAP

• IQ19 Poor Registration RAP.

IQ1 Internal Test Patterns

Table 1 defines the image defect, gives a description of the defect and identifies the optimum

test pattern to be used.

NOTE: There are 19 internal test patterns, but only 7 are unique. Each test pattern is available

more than one time. Only the first occurrence of a test pattern is shown in Table 1.

Table 2 describes the test patterns and the purpose for which they should be used to identify

image quality defects.

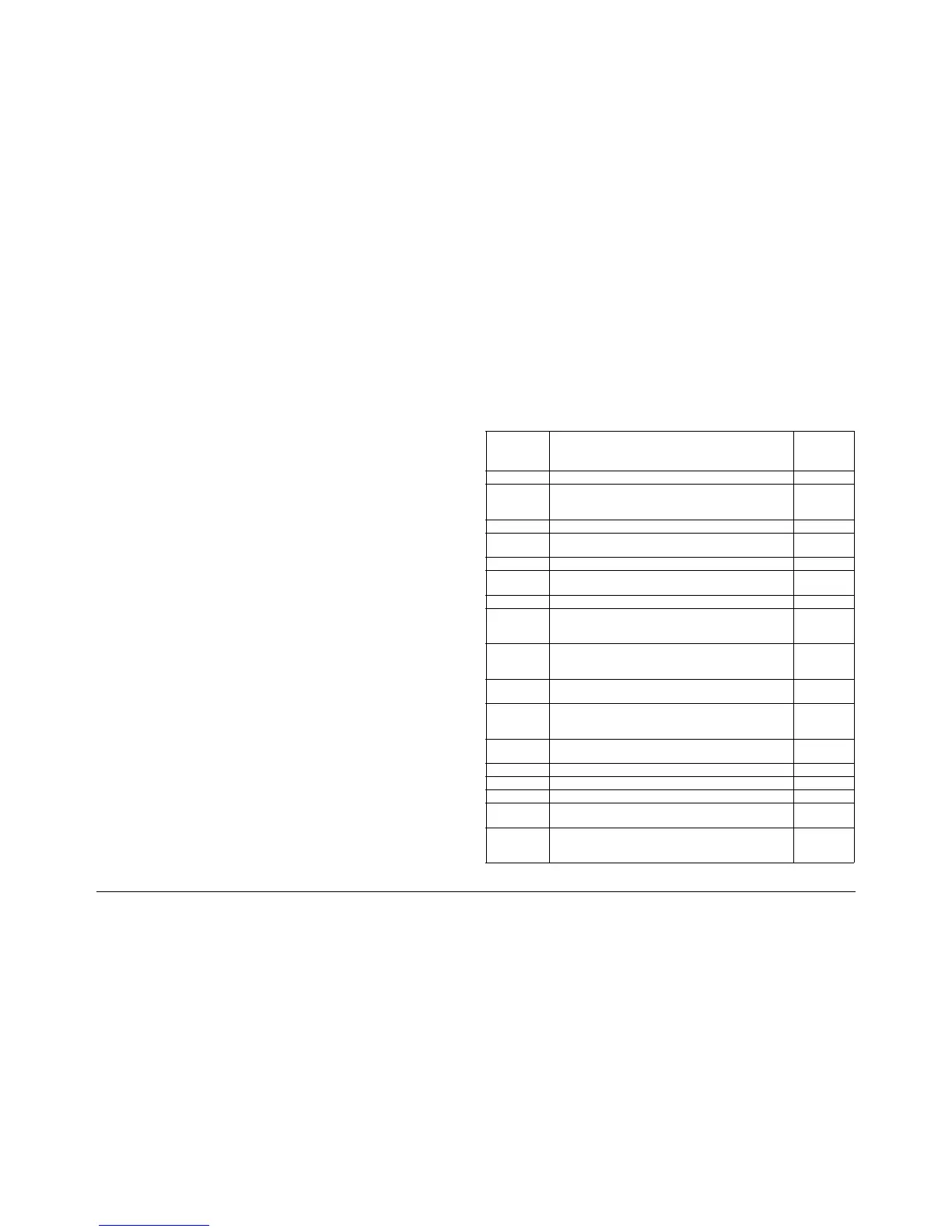

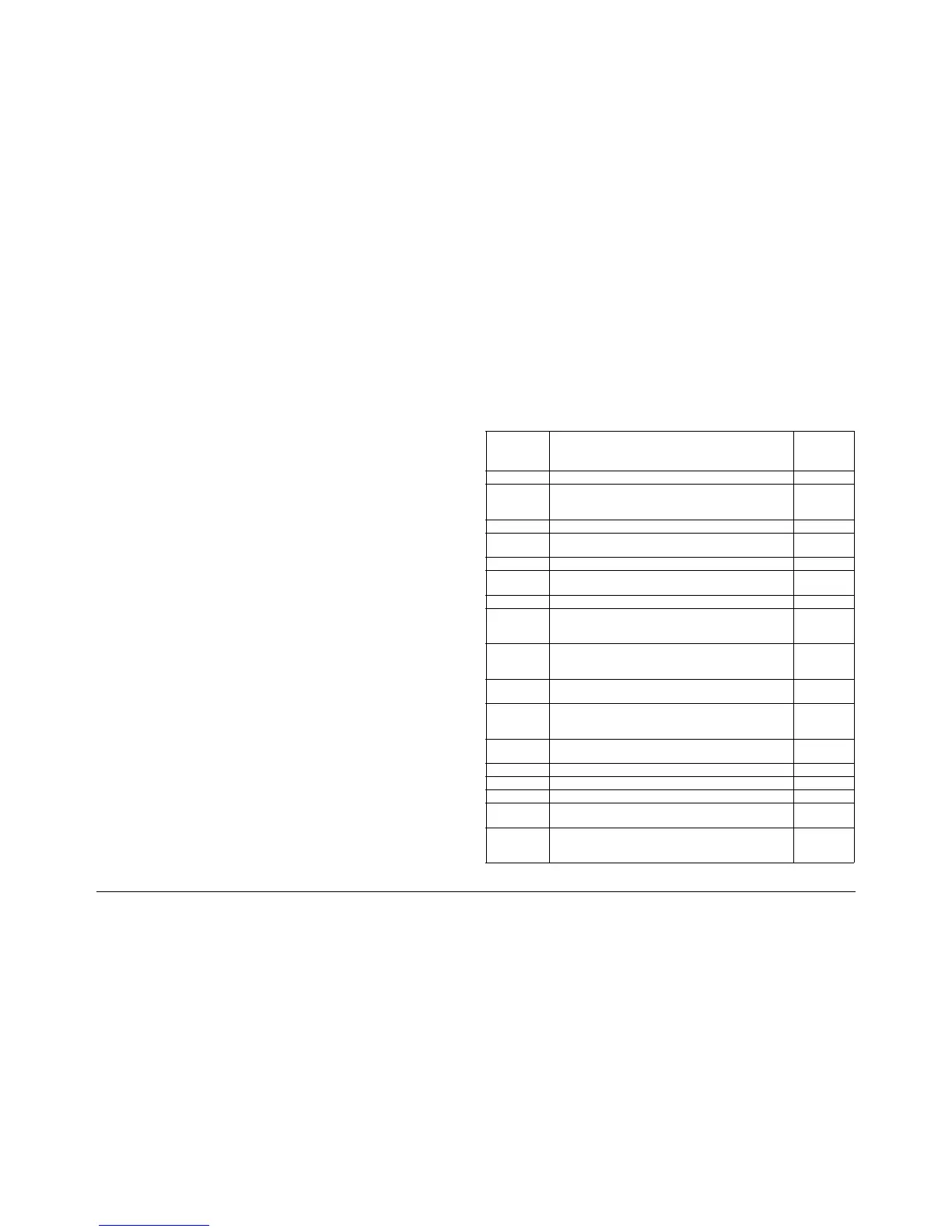

Table 1 Image quality defects

Image quality

defect Description of defect

Optimum

internal test

pattern

Background Uniform darkening across all the non print areas 1

Bands Grey to dark in the light or non-image areas of the print in the

process direction or across the process direction. See also

narrow bands.

1

Beads on print Developer beads in the light or non-image areas of the print. 1, 7, 8

Black image A print that is black or grey all over, but has no visible image

of the original document.

1, 7, 8

Blank image No visible image. 1, 7, 8

Blurred image Part or whole of the image has the appearance of being out

of focus.

1, 7, 8

Dark prints Very dark background with a visible image. 1, 7, 8

Deletions Areas of the image missing from the print. Deletions may be

in the form of white spots, marks, lines, or whole areas of

toner missing from the print.

1, 6

Displaced and

fragmented

image

Distorted images, part images and missing images (scram-

bled images). Displaced images.

1

Light image The image is visible on the print, but with insufficient solid

area density.

1

Lines Black or white lines across the process direction or in the pro-

cess direction. See also the description, displaced and frag-

mented image.

1, 7

Magnification At 100% magnification the printed image differs from the size

of the image on the original document.

7

Marks Dark marks in the non-image areas of the print. 1, 7

Misregistration The image on the paper is misregistered. 7

Narrow Bands Bands across the process direction visible in halftone areas. 1, 4, 5

Non uniformity Variation in image quality and density across the print. See

also uneven density.

4, 5

Offsetting A previous image that was not removed from the fuser roll

during the cleaning cycle. The image is repeated at regular

intervals.

1, 5

Loading...

Loading...