5.11 Troubleshooting without Fault Display

YASKAWA ELECTRIC EZZ010928 FSDrive-MV1000 Instructions 157

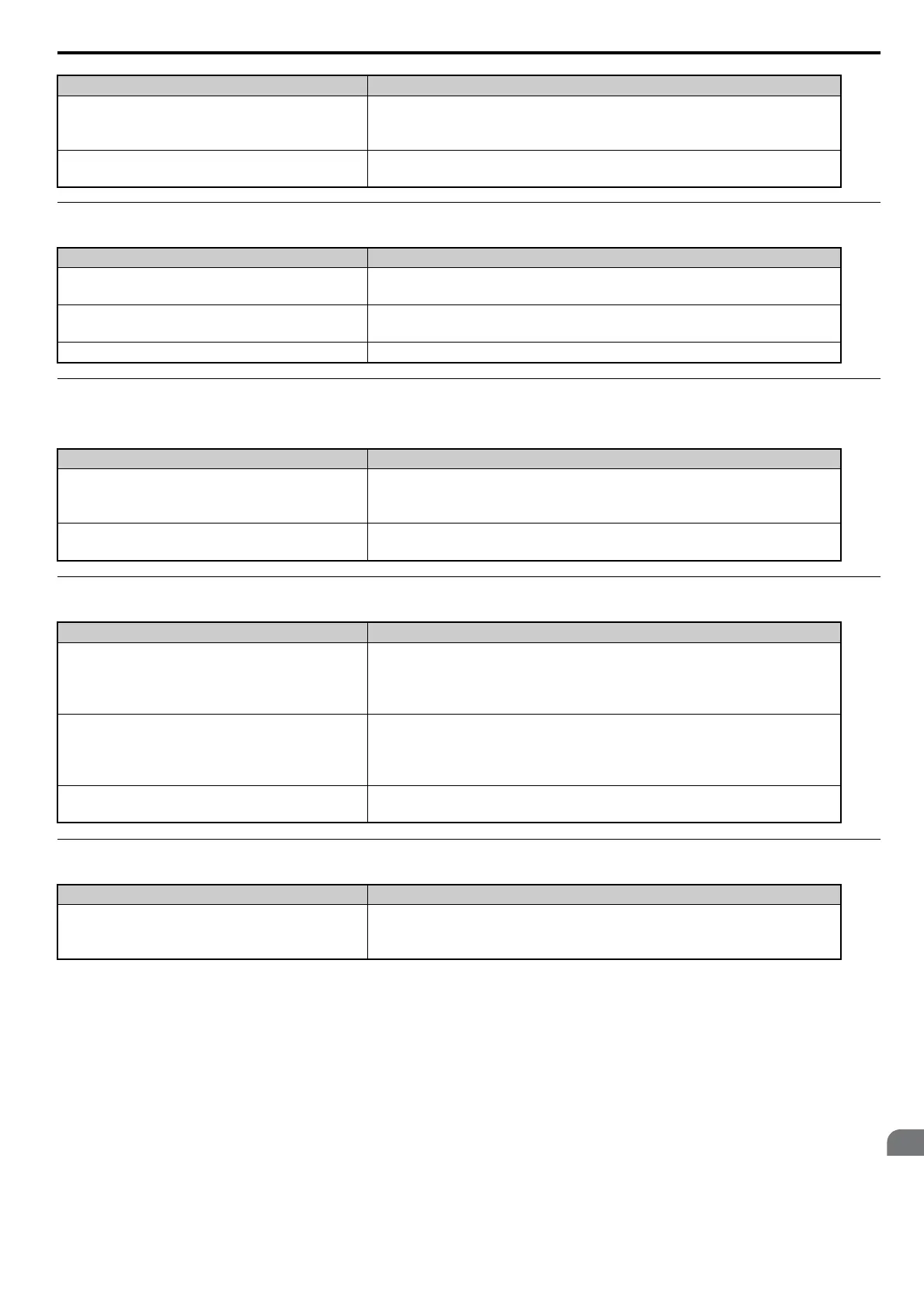

◆ Insufficient Starting Torque

◆ Motor Rotates After the Drive Output is Shut Off (Motor Rotates During DC Injection

Braking)

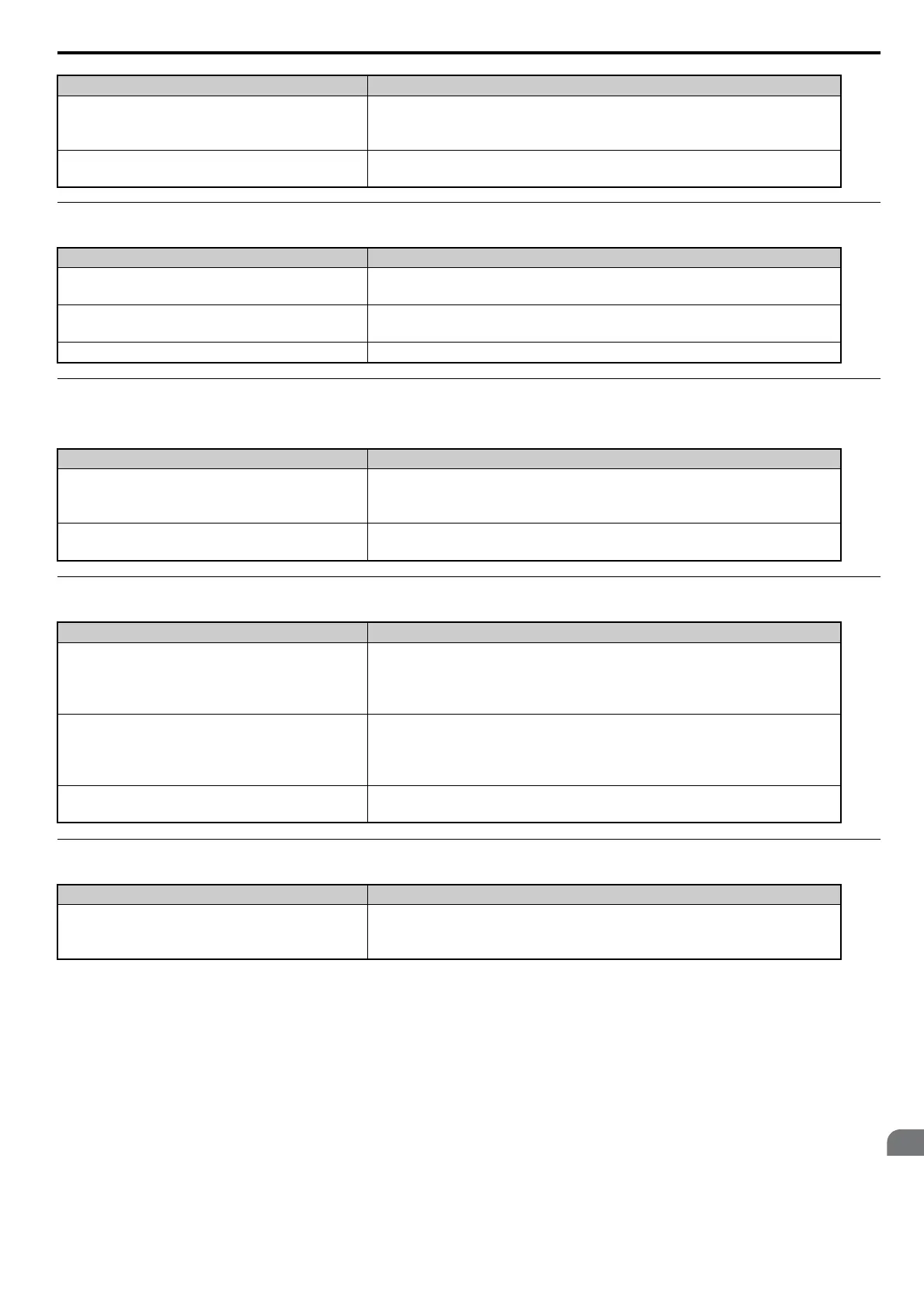

◆ Output Frequency is not as High as Frequency Reference

◆ Motor Does Not Restart after Power Loss

Reverse drive output frequency and speed detection.

When output frequency rises, the sensor detects a

speed decrease.

⇒Set PID output for reverse characteristics (b5-09 = 1).

Adjustment made to PID parameter settings are

insufficient.

⇒ Make the adjustments by referring to the information on the PID control

parameters (b5-) in the separate FSDrive-MV1000 Parameter Guide.

Cause Possible Solutions

Auto-Tuning has not yet been performed (required for

vector control modes).

Perform Auto-Tuning. Refer to Motor Performance Fine-Tuning on page 110.

The control mode was changed after performing

Auto-Tuning.

Perform Auto-Tuning again.

Only Stationary Auto-Tuning was performed. Perform Rotational Auto-Tuning.

Cause Possible Solutions

DC Injection Braking is set too low and the drive

cannot decelerate properly.

⇒Adjust the DC Injection braking settings.

• Increase the current level for DC Injection Braking (b2-02).

• Increase the DC Injection Braking time at stop (b2-04).

The stopping method is set so that the drive coasts to

stop.

Set b1-03 (Stopping Method Selection) to 0 or 2.

Cause Possible Solutions

Frequency reference is set within the range of the

Jump frequency.

⇒Adjust the parameters used for the Jump frequency function (d3-01, d3-02, d3-

03, d3-04).

Note: Enabling the Jump frequency prevents the drive from outputting

the frequencies specified in the Jump range.

Upper limit for the frequency reference has been

exceeded.

⇒Set the maximum output frequency and the upper limit for the frequency

reference to more appropriate values (E1-04, d2-01).

Note: The following calculation yields the upper value for the output

frequency = E1-04 x d2-01 / 100

Large load triggered Stall Prevention function during

acceleration.

⇒Reduce the load.

⇒Adjust the Stall Prevention level during acceleration (L3-02).

Cause Possible Solutions

The Run command was not issued again when power

was restored.

Check the sequence and wiring that has been set up to enter the Run command.

⇒A relay should be set up to make sure the Run command remains enabled

throughout any power loss.

Cause Possible Solutions

Loading...

Loading...