Periodic Inspection and Maintenance

8

8.2 Inspection

YASKAWA SIEPYAIH6B01A HV600 AC Drive Bypass Technical Reference 557

DANGER! Electrical Shock Hazard. Do not examine, connect, or disconnect wiring on an energized bypass. Before servicing,

disconnect all power to the equipment and wait for the time specified on the warning label at a minimum. The internal capacitor

stays charged after the bypass is de-energized. The charge indicator LED extinguishes when the DC bus voltage decreases below

50 Vdc. When all indicators are OFF, remove the covers before measuring for dangerous voltages to make sure that the bypass is

safe. If you do work on the bypass when it is energized, it will cause serious injury or death from electrical shock.

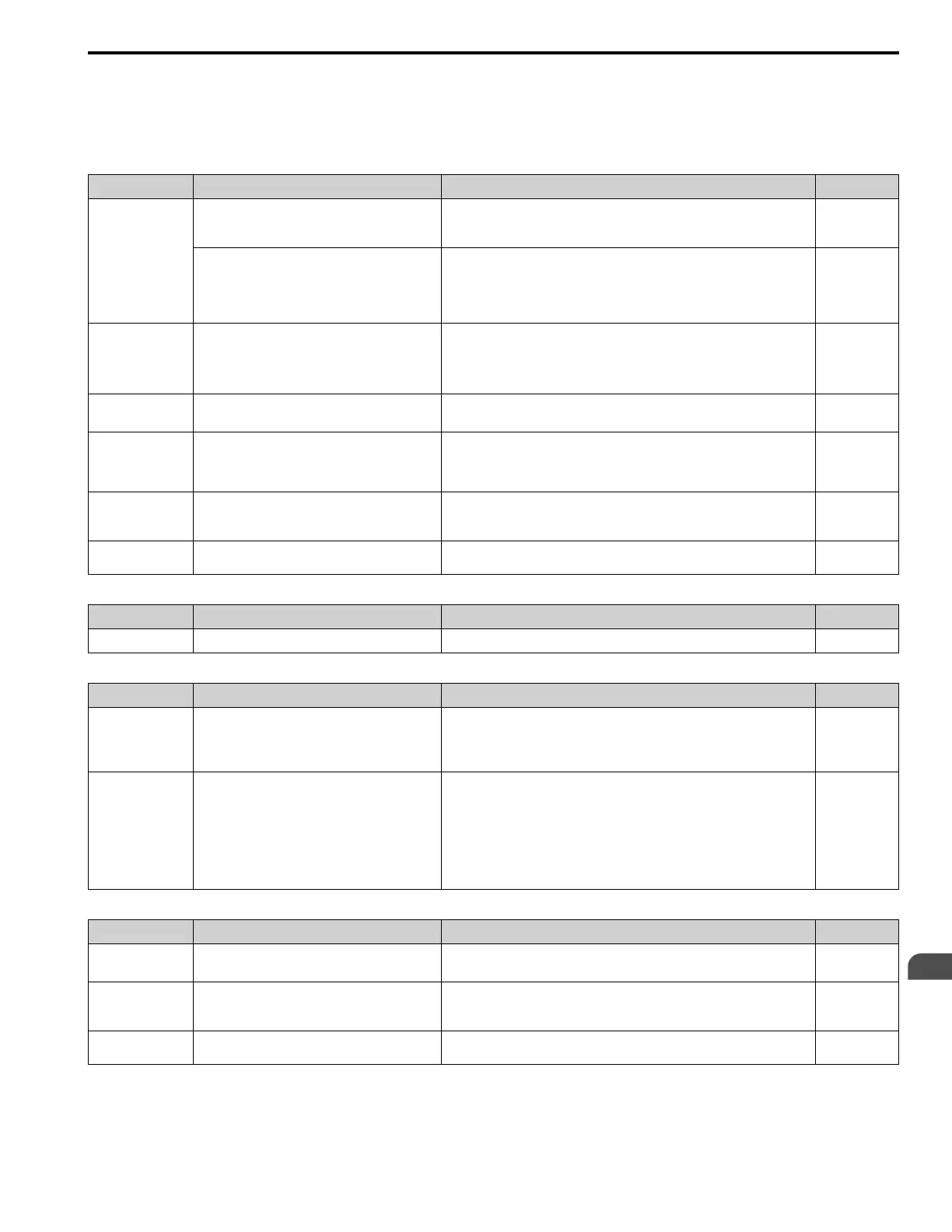

Table 8.2 Main Circuit Periodic Inspection Checklist

Inspection Area Inspection Points Corrective Action Checked

General

• Examine equipment for discoloration from too

much heat or deterioration.

• Examine for damaged parts.

• Replace damaged components as necessary.

• The drive does not have many serviceable parts and it could be necessary to

replace the drive.

Examine for dirt, unwanted particles, or dust on

components.

• Examine enclosure door seal.

• Use a vacuum cleaner to remove unwanted particles and dust without touching

the components.

• If you cannot remove unwanted particles and dust with a vacuum cleaner,

replace the components.

Conductors and

Wiring

• Examine wiring and connections for discoloration

or damage. Examine wiring and connections for

discoloration from too much heat.

• Examine wire insulation and shielding for

discoloration and wear.

Repair or replace damaged wiring.

Terminal Block

Examine terminals for stripped, damaged, or loose

connections.

• Tighten loose screws.

• Replace damaged screws or terminals.

Electromagnetic

Contactors and

Relays

• Examine contactors and relays for too much noise

during operation.

• Examine coils for signs of too much heat, such as

melted or broken insulation.

• Check coil voltage for overvoltage or undervoltage conditions.

• Replace broken relays, contactors, or circuit boards that you can remove.

Electrolytic capacitor

• Examine for leaks, discoloration, or cracks.

• Examine if the cap has come off, if there is

swelling, or if there are leaks from broken sides.

The drive does not have many serviceable parts and it could be necessary to replace

the drive.

Diodes, IGBT (Power

Transistor)

Examine for dust or other unwanted material collected

on the surface.

Use a vacuum cleaner to remove unwanted particles and dust without touching the

components.

Table 8.3 Motor Periodic Inspection Checklist

Inspection Area Inspection Points Corrective Action Checked

Operation Check Check for increased vibration or unusual noise. Stop the motor and contact approved maintenance personnel as necessary.

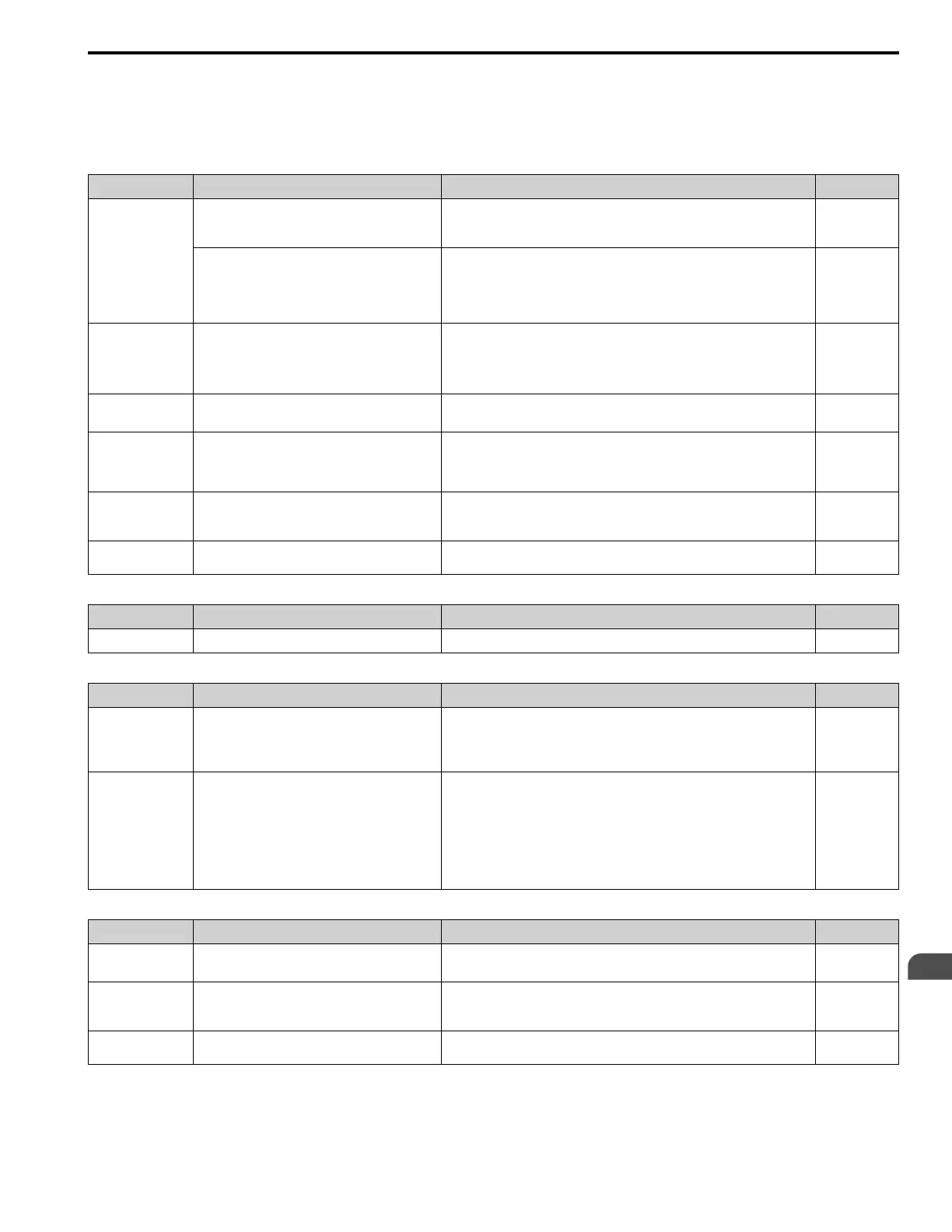

Table 8.4 Control Circuit Periodic Inspection Checklist

Inspection Area Inspection Points Corrective Action Checked

General

• Examine terminals for stripped, damaged, or loose

connections.

• Make sure that all terminals have been correctly

tightened.

• Tighten loose screws.

• Replace damaged screws or terminals.

• If terminals are integral to a circuit board, it could be necessary to replace the

control board or the drive.

Circuit Boards

• Check for odor, discoloration, or rust.

• Make sure that all connections are correctly

fastened.

• Make sure that the surface of the circuit board does

not have dust or oil mist.

• Tighten loose connections.

• Use a vacuum cleaner to remove unwanted particles and dust without touching

the components.

• If you cannot remove unwanted particles and dust with a vacuum cleaner,

replace the components.

• Do not use solvents to clean the board.

• The drive does not have many serviceable parts and it could be necessary to

replace the drive.

Table 8.5 Cooling System Periodic Inspection Checklist

Inspection Area Inspection Points Corrective Action Checked

Cooling fan

• Check for unusual oscillation or unusual noise.

• Check for damaged or missing fan blades.

Clean or replace the fans as necessary.

Heatsink

• Examine for dust or other unwanted material

collected on the surface.

• Examine for dirt.

Use a vacuum cleaner to remove unwanted particles and dust without touching the

components.

Air Duct

Examine air intake, exhaust openings and make sure

that there are no unwanted materials on the surface.

Clear blockages and clean air duct as necessary.

Loading...

Loading...