5-1

IM80B80T10E 21th Edition : Jul.1,2007-00

< 5.MAINTENANCE >

5. MAINTENANCE

The EML500 has been strictly adjusted during the production process. Furthermore, the use of

highly integrated circuits has eliminated moving parts; thus ensuring greater reliability. However,

daily inspection and periodic maintenance are necessary for accurate and stable operation of the

system.

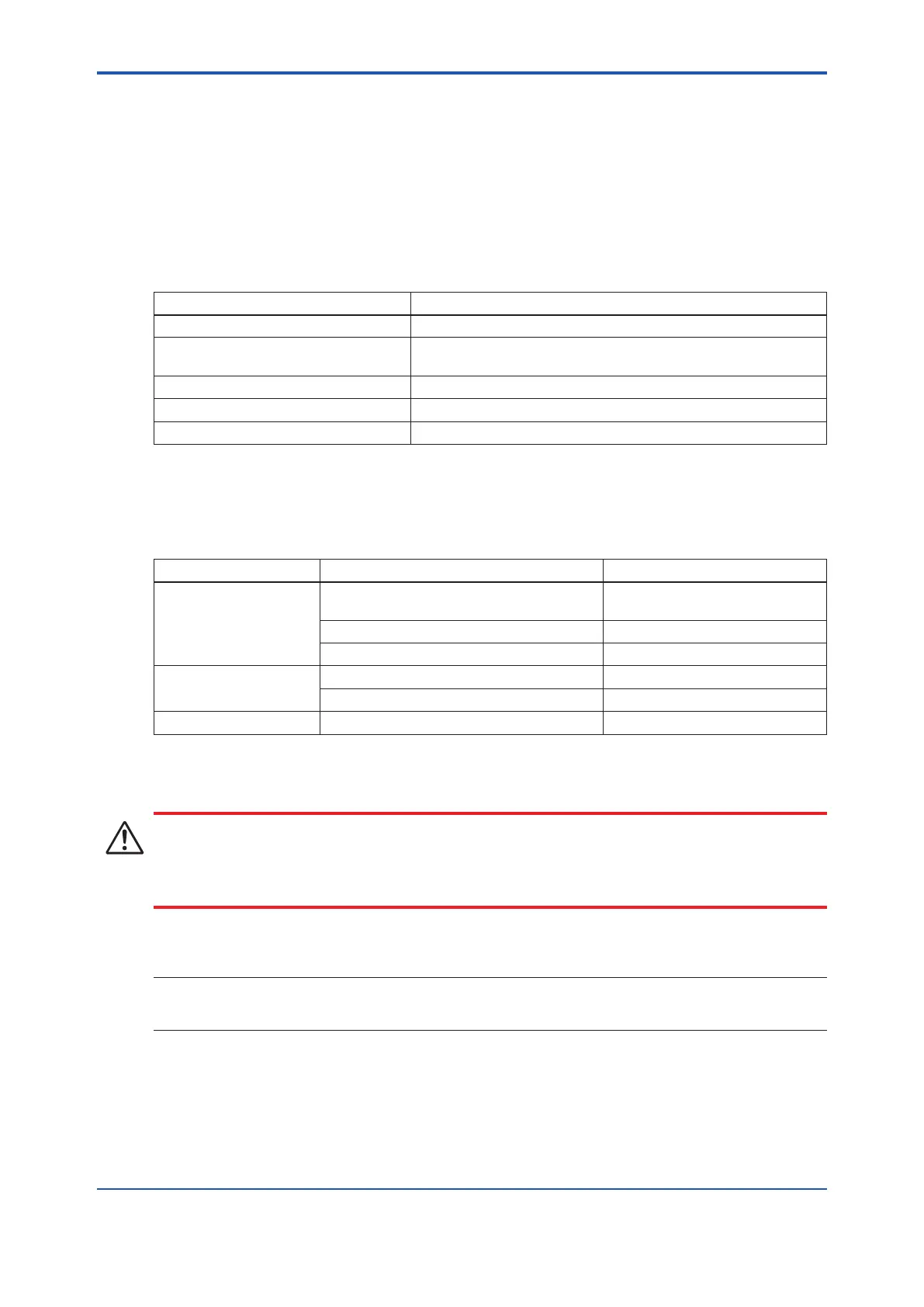

5.1 Daily Inspection

Inspection Item Description

Dimmer Check the dimmer function.

Speed indicator Check that the reading of the speed indicator is identical to the speed

on the master indicator.

Distance display Check the displayed distance with respect to the speed display.

Error indicator Check that there is no error indicated in the master unit.

Lamp test Do the lamp test to check the lighting of the LEDs.

5.2 Periodic Inspection

Inspection Item Description Frequency of Inspection

Sensor Check for contamination on the electrodes in

the sensor, and clean it off.

Once every three months

Check the wiring connections. Every year

Check the connector. Every year

Master indicator Check the display and individual LEDs. Once every 6 months

Check the speed using test output Once every 6 months

Speed indicator Check the lighting. Once every 6 months

Note: Refer to Section 6.4(1) for cleaning the electrode.

CAUTION

Do not use a megger for inspection purposes except for on board power supply terminals.

Otherwise, the equipment may be damaged.

NOTE

If there are contaminants or microorganisms adhering to or around the sensor electrode, the speed

cannot be measured accurately. The tip of the sensor must be kept clean.

Loading...

Loading...